A kind of water-based anti-graffiti paint

An anti-graffiti and coating technology, applied in the direction of coating, etc., can solve the problems that indoor wall coatings cannot be used, anti-graffiti materials are not environmentally friendly, and cannot prevent graffiti, so as to improve scrubability, scrub resistance, and enhancement The effect of wetting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

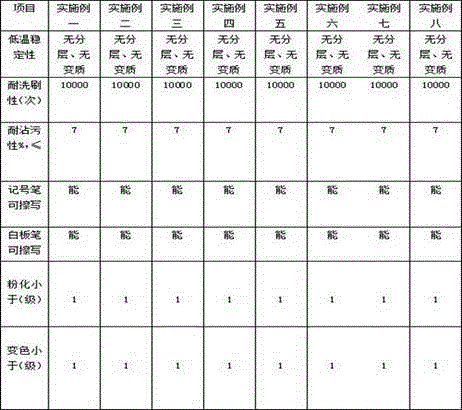

Examples

Embodiment 1

[0042] 1. Preparation of fluorine-containing nano-silica dispersion: Add 70 kg of deionized water into the mixer, and then add 20 kg of nano-silica, 5 kg of fluorine-containing surfactant, and dispersant under low-speed stirring (400rpm) 4 kg, 1 kg of defoamer, after high-speed dispersion for 30 minutes, add to the grinder for high-speed grinding (1000rpm), until the fineness is 5 μm, then filter to make a fluorine-containing nano-silica dispersion;

[0043] 2. Preparation of dispersion slurry: Add 200 kg of deionized water into the mixer, add 5 kg of dispersant, 2 kg of defoamer, 1 kg of wetting agent, 10 kg of film-forming aid, 175 kg of heavy calcium powder, 150 kg of titanium dioxide, high-speed dispersion (1000rpm) for 45 minutes, and filter to a fineness of 30 μm to make a dispersion slurry;

[0044] 3. Preparation of film-forming material: Add 300 kg of EVA emulsion, 150 kg of fluorosilicone resin, and 50 kg of coupling agent into a stirring tank and fully mix to form a...

Embodiment 2

[0047] 1. Preparation of fluorine-containing nano-silica dispersion: Add 65 kg of deionized water into the mixer, and then add 25 kg of nano-silica, 5 kg of fluorine-containing surfactant, and dispersant in turn under low-speed stirring (450rpm) 4 kg, 1 kg of defoamer, high-speed dispersion at 800 rpm for 45 minutes, then added to a grinder for high-speed grinding (1000 rpm), until the fineness is 5 μm, and then filtered to make a fluorine-containing nano-silica dispersion.

[0048] 2. Preparation of dispersion slurry: Add 250 kg of deionized water into the mixer, add 5 kg of dispersant, 2 kg of defoamer, 1 kg of wetting agent, 15 kg of film-forming aid, Heavy calcium powder 200kg, titanium dioxide 200kg, high-speed dispersion (1000rpm) for 45 minutes, until the fineness is 30μm and filtered to make dispersion slurry.

[0049]3. Preparation of film-forming material: Add 350 kg of EVA emulsion, 100 kg of fluorosilicone resin, and 50 kg of coupling agent into a stirring tank and...

Embodiment 3

[0052] 1. Preparation of fluorine-containing nano-silica dispersion: Add 40 kg of deionized water into the mixer, and then add 30 kg of nano-silica, 6 kg of fluorine-containing surfactant, and dispersant under low-speed stirring (450rpm) 4 kg, 0.75 kg of defoamer, high-speed dispersion at 1500 rpm for 15 minutes, then added to a grinder for high-speed grinding (1200 rpm), until the fineness is 5 μm, then filtered to make a fluorine-containing nano-silica dispersion.

[0053] 2. Preparation of dispersion slurry: Add 160 kg of deionized water into the mixer, add 6 kg of dispersant, 1 kg of defoamer, 0.9 kg of wetting agent, 18 kg of film-forming aid, 60 kg of heavy calcium powder, 60 kg of titanium dioxide, disperse at high speed (1000rpm) for 15 minutes, and filter to a fineness of 30 μm to make a dispersion slurry;

[0054] 3. Preparation of film-forming material: Add 200 kg of EVA emulsion, 200 kg of fluorosilicone resin, and 12 kg of coupling agent into a stirring tank and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com