Multiplex aldehyde-removal internal wall latex paint and preparation method thereof

A technology of aldehyde interior wall and latex paint, applied in the field of aldehyde removal paint and its preparation, multiple aldehyde removal interior wall latex paint and its preparation field, can solve the problems of poor durability, low efficiency, single aldehyde removal effect, etc., and achieve improved air quality Quality, improve air quality, improve aldehyde removal efficiency and its persistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

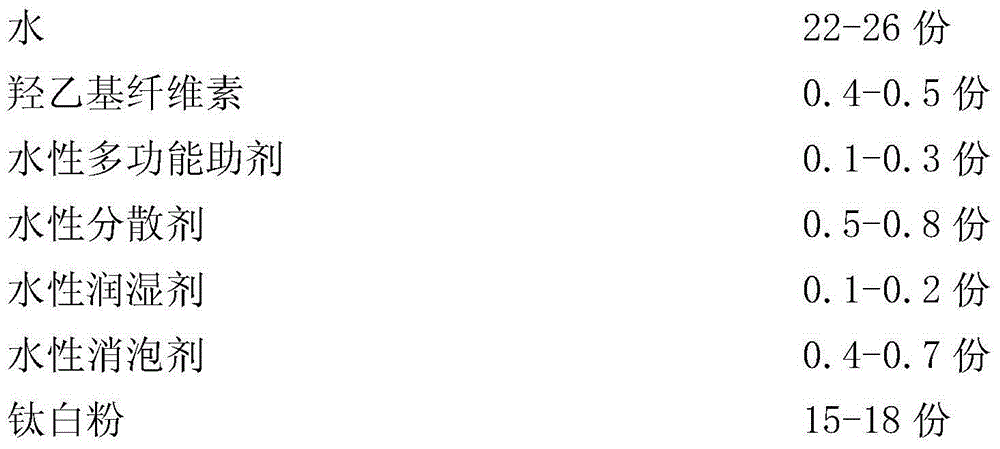

[0031] A multiple aldehyde-removing interior wall latex paint, which is prepared from the following raw materials according to the following mass ratio through the following steps:

[0032] (1) Add 22-26 parts of water into the dispersing tank, add 0.4-0.5 parts of hydroxyethyl cellulose and 0.1-0.3 parts of water-based multifunctional additives in sequence at a speed of 350-550r / min, and disperse for 1-3 minutes;

[0033] (2) After increasing the speed to 800-1000r / min, add 0.5-0.8 parts of water-based dispersant, 0.1-0.2 parts of water-based wetting agent, 0.4-0.7 parts of water-based defoamer, 15-18 parts of titanium dioxide, 8- After 10 parts of kaolin, 10-15 parts of calcium carbonate, 4-5 parts of diatomaceous earth, 2-3 parts of negative ion slurry and 1-2 parts of imidazolidinone, increase the speed again to 1800-2000r / min and disperse for 15-20min , and then detect whether the fineness is ≤60 μm, and if the fineness is ≤60 μm, proceed to step (3);

[0034] (3) After ...

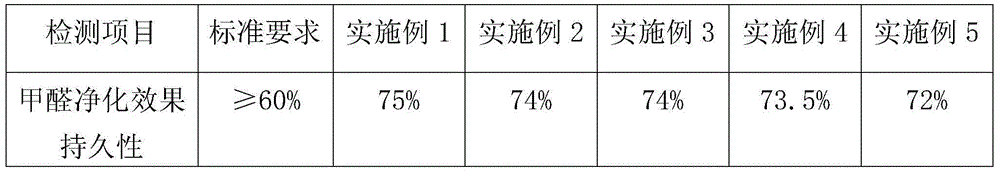

Embodiment 1

[0036] Embodiment 1 (best embodiment)

[0037] A multiple aldehyde-removing interior wall latex paint, which is prepared from the following raw materials according to the following mass ratio through the following steps:

[0038] (1) Add 24.3 parts of water into the dispersing tank, add 0.45 parts of hydroxyethyl cellulose and 0.15 parts of water-based multi-functional additives in sequence at 450r / min, and disperse for 2 minutes;

[0039] (2) After increasing the rotation speed to 900r / min, add 0.6 parts of water-based dispersant, 0.2 parts of water-based wetting agent, 0.6 parts of water-based defoamer, 16 parts of titanium dioxide, 8 parts of kaolin, 13 parts of calcium carbonate, and 5 parts of silicon After algal earth, 2 parts of negative ion slurry and 1.5 parts of imidazolidinone, increase the speed again to 1900r / min and disperse for 18 minutes, then check whether the fineness is ≤60 μm, and if the fineness is ≤60 μm, continue to step (3);

[0040] (3) After reducing...

Embodiment 2

[0042] A multiple aldehyde-removing interior wall latex paint, which is prepared from the following raw materials according to the following mass ratio through the following steps:

[0043] (1) Add 25.9 parts of water into the dispersing tank, add 0.45 parts of hydroxyethyl cellulose and 0.15 parts of water-based multifunctional additives in sequence at a speed of 550r / min, and disperse for 3 minutes;

[0044](2) After increasing the speed to 1000r / min, add 0.6 parts of water-based dispersant, 0.2 parts of water-based wetting agent, 0.5 parts of water-based defoamer, 15 parts of titanium dioxide, 10 parts of kaolin, 13 parts of calcium carbonate, and 4 parts of silicon After diatomaceous earth, 2.5 parts of negative ion slurry and 1.5 parts of imidazolidinone, increase the speed again to 2000r / min and disperse for 20 minutes, then check whether the fineness is ≤60 μm, and if the fineness is ≤60 μm, continue to step (3);

[0045] (3) After reducing the speed to 1200r / min, add 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com