High temperature slag waste heat recovery system and method

A waste heat recovery system and waste heat recovery technology, applied in the direction of recycling technology, etc., can solve the problems of not fully considering the impact of the slag treatment system on production equipment, etc., and achieve the effect of compact layout, solving environmental pollution problems, and high sensible heat efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

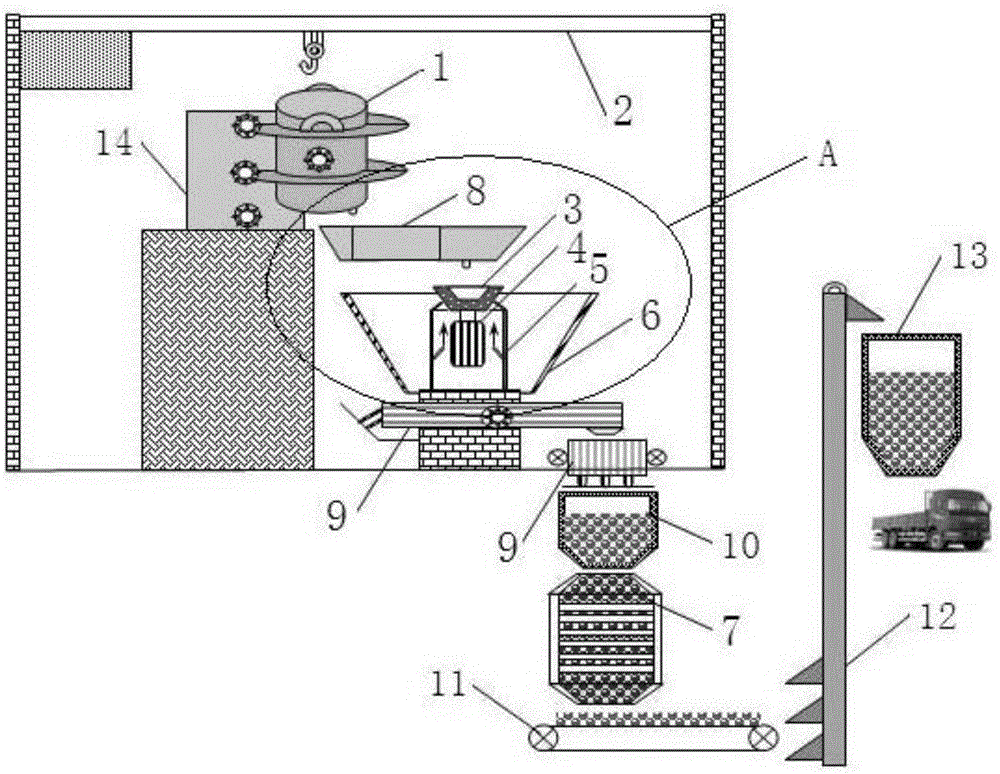

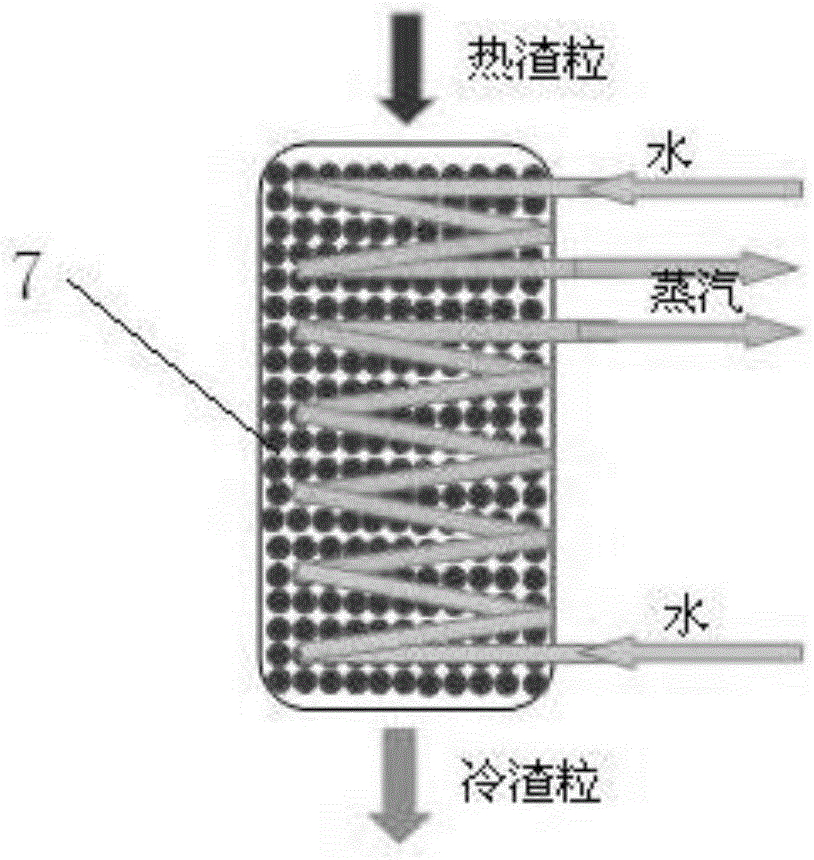

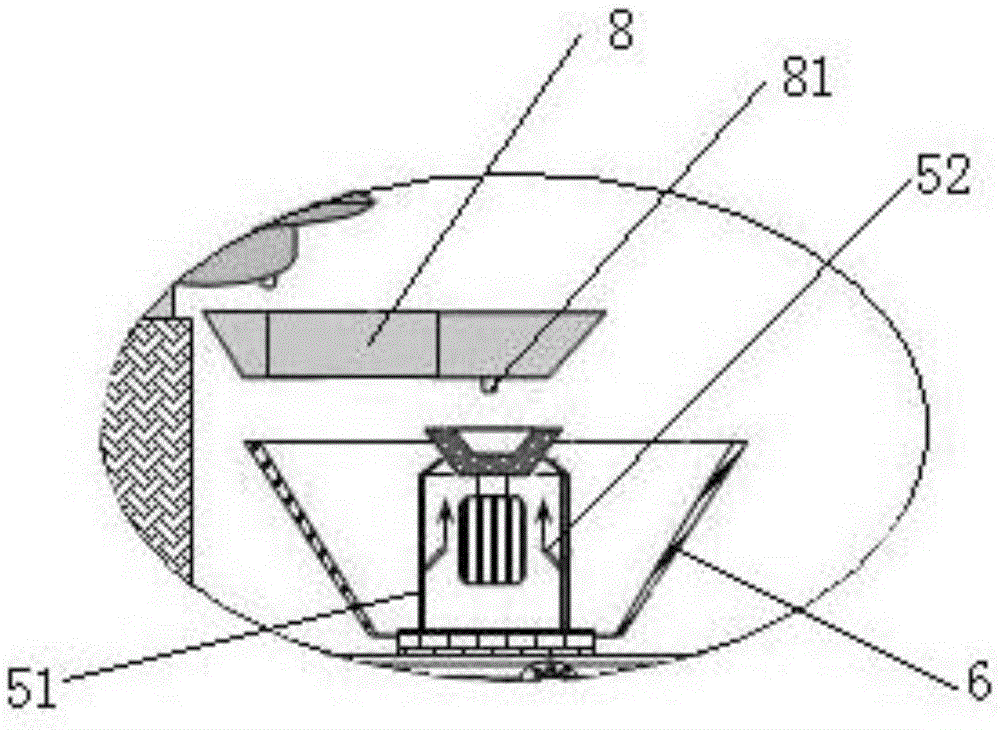

[0028] As shown in the figure, the high-temperature slag waste heat recovery system in this embodiment includes a slag conveying unit, a slag granulation unit for granulating slag, and a slag granulation unit for granulating the slag particles formed after granulation. A waste heat recovery unit for waste heat recovery; the slag conveying unit is mainly composed of a slag tank 1 and a crane 2 for conveying the slag tank 1; the slag granulation unit is mainly composed of a rotor 3 for granulating slag, a rotor 3 The rotating device 4 providing the rotating power, the granulation cooling device 5 used for cooling the rotor cup 3 and the rotating device 4, and the slag collection cooling device 6 used for cooling the splashed slag of the rotor cup and the granulation cooling device 5 , the granulation cooling device 5 is arranged on the periph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com