Completely biodegradable waterproof paper

A biodegradable, waterproof paper technology, applied in papermaking, paper coatings, textiles and papermaking, etc., can solve the problems of white pollution, difficult to biodegrade, not completely biodegradable, etc., and achieve good hydrophobicity and good adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

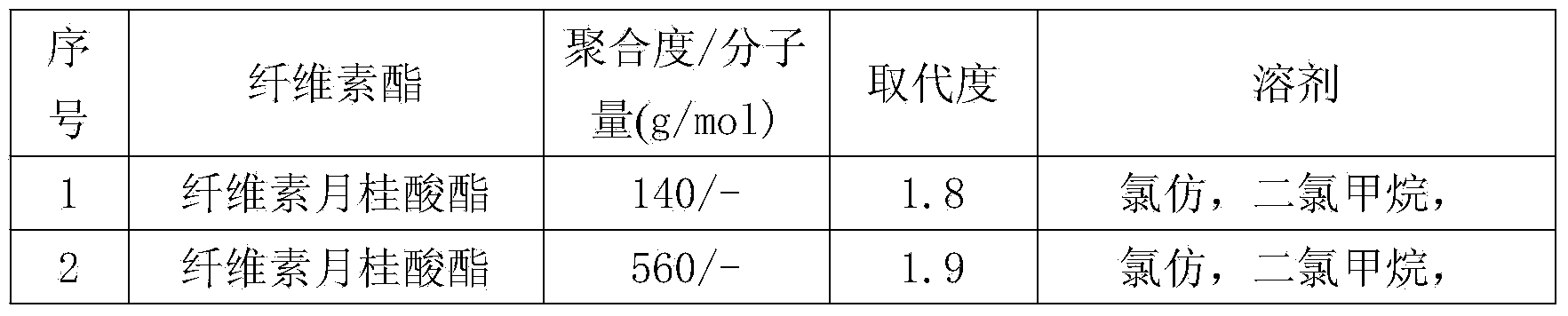

[0018] Embodiment 1 cellulose ester coating (dipping method)

[0019] Dissolve cellulose laurate in dichloromethane to form a solution with a concentration of 1mg / mL. Immerse plain paper in the solution for 30 seconds, take it out and dry it naturally. The thickness of the coating formed on the surface is 3nm (measured by atomic force microscope AFM) ), the weight gain ratio is 11%, the measured contact angle (static contact angle meter) is 88°, and the paper contact angle is 25°. Put the dried paper horizontally into water and soak for 1 minute, take it out and weigh it, the weight gain ratio is 47.6%, which is lower than the water absorption weight gain ratio of untreated paper 176.3%. In the case of water immersion, the strength of waterproof paper does not decrease, while the strength of ordinary paper is already very low, and almost completely loses its strength. After natural drying at 30°C, the weight and shape of the waterproof paper were completely recovered, while t...

Embodiment 2

[0028] Embodiment 2 cellulose ester coating (dipping method)

[0029] Cellulose laurate is dissolved in chloroform to form a solution with a mass concentration of 3 mg / mL, the paper is immersed in the solution for 30 seconds, taken out and dried naturally, the thickness of the coating formed on the surface is 6nm measured by atomic force microscope (AFM), increasing The weight ratio was 24%, and the measured contact angle (static contact angle meter) was 95°. Put it horizontally into water and soak for 1 minute, take it out and weigh it, the weight gain ratio is 20.8%, which is far lower than the weight gain ratio of untreated paper which is 176.3%. In the case of water immersion, the strength of waterproof paper does not decrease, while the strength of ordinary paper is already very low, and almost completely loses its strength. After natural drying at 30°C, the weight and shape of the waterproof paper were completely recovered, while the weight of the ordinary paper was rec...

Embodiment 3

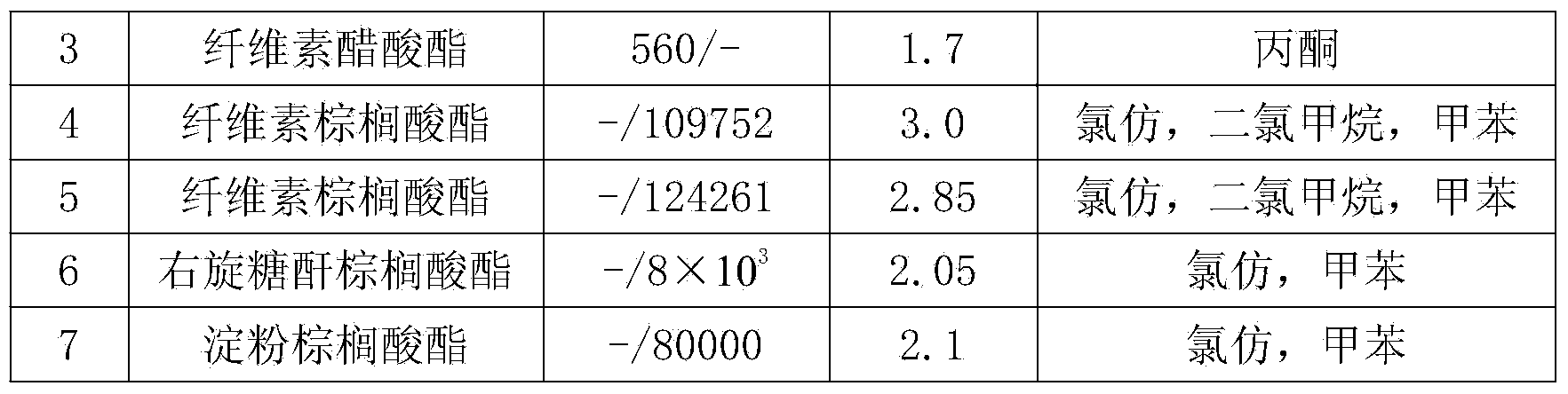

[0030] Embodiment 3 cellulose ester coating (dipping method)

[0031] Cellulose palmitate was dissolved in chloroform to form a 50mg / mL solution, and the paper was horizontally immersed in the solution for 20s, 40s, 60s and 3min respectively. The results are shown in Table 2. In the case of water immersion, the strength of waterproof paper does not decrease, while the strength of ordinary paper is already very low, and almost completely loses its strength. After natural drying at 30°C, the weight and shape of the waterproof paper were completely restored. Although the weight of the ordinary paper recovered, it was seriously warped and deformed. The details are shown in Table 2:

[0032] Table 2 Example 5 Dip Coating Example

[0033] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com