Method for measuring inductance parameter of permanent magnet synchronous motor

A permanent magnet synchronous motor, inductance parameter technology, applied in the measurement device, measuring electrical variables, measuring resistance/reactance/impedance, etc. Measurement deviation accumulation and other problems, to achieve the effect of easy implementation, high measurement accuracy, and accurate inductance parameter measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

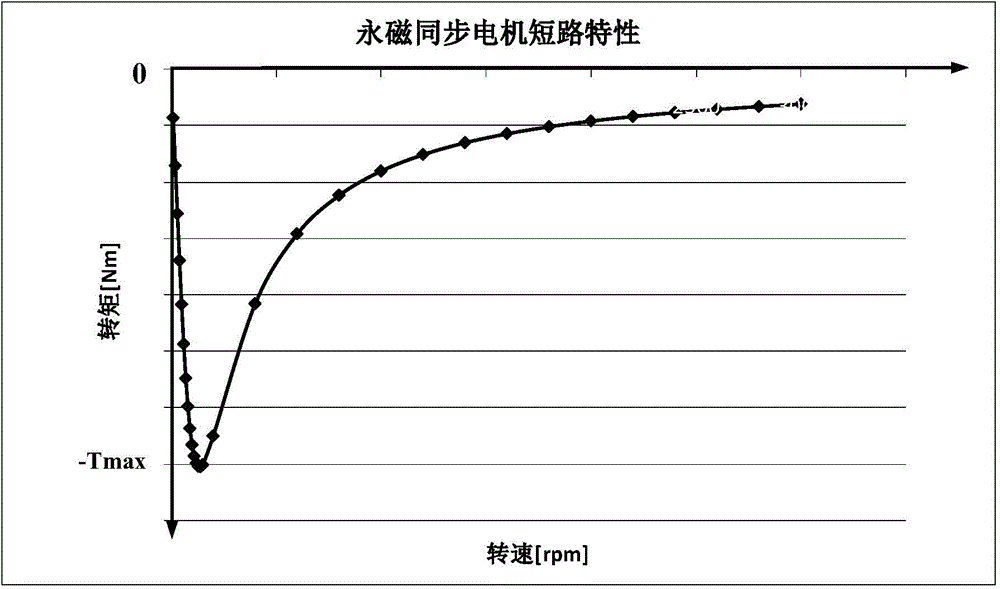

[0044] The purpose of the invention is to measure the inductance parameter of the permanent magnet synchronous motor through the three-phase short circuit of the motor.

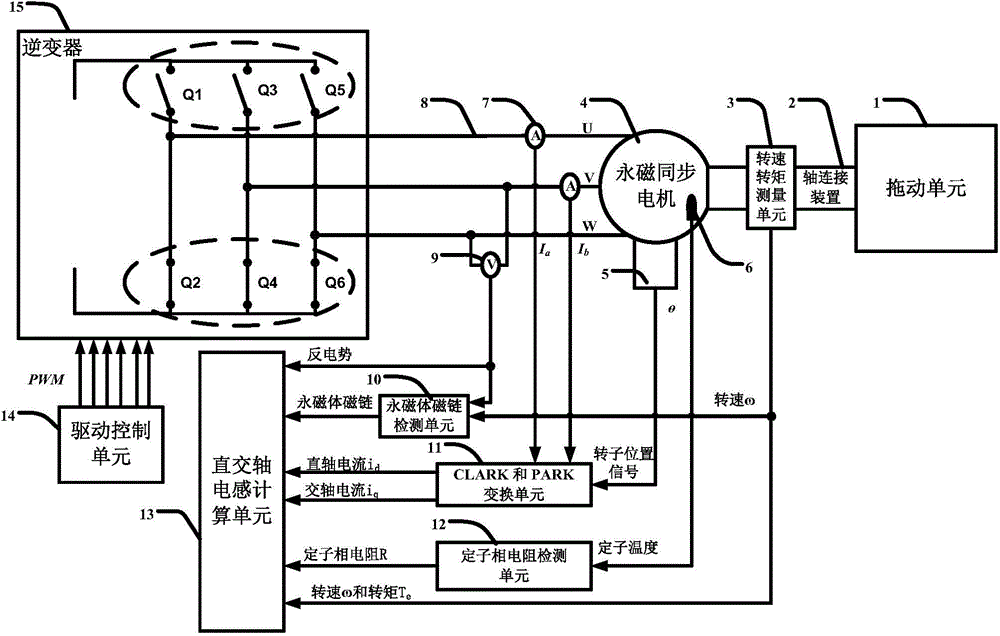

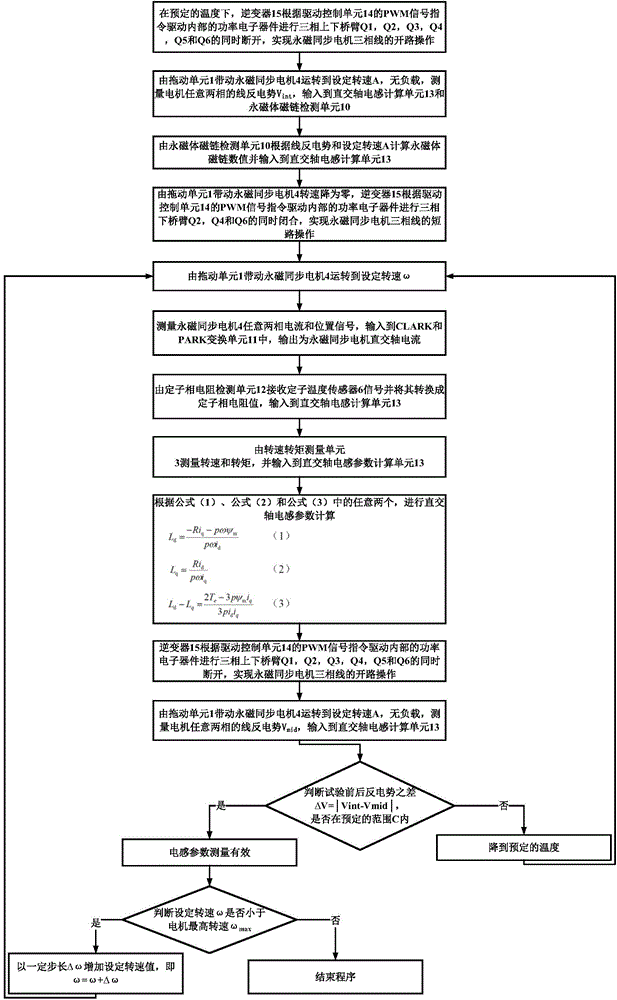

[0045] Such as figure 1 As shown, the drag unit 1 is used to drag the permanent magnet synchronous motor 4 to the set speed ω; the shaft connection device 2 is used to connect the mechanical interface between the drag unit 1 and the permanent magnet synchronous motor 4; the speed torque measurement unit 3 Used to measure the rotational speed ω and torque T of the mechanically connected shaft between the drag unit 1 and the permanent magnet synchronous motor 4 e The motor position sensor 5 is used to detect the absolute position of the motor rotor, which is an absolute position sensor, such as a resolver or an absolute position photoelectric encoder; the stator temperature sensor 6 is used to detect the motor stator temperature; the current sensor 7 is used to detect the phase current, It can be a non-contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com