Method for forming self-aligned metal silicide

A metal silicide, metal silicide layer technology, applied in electrical components, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems affecting surface uniformity, unavoidable, metal silicide morphology defects, etc., to improve Interface states, repairs and defects, effects of reducing or avoiding surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

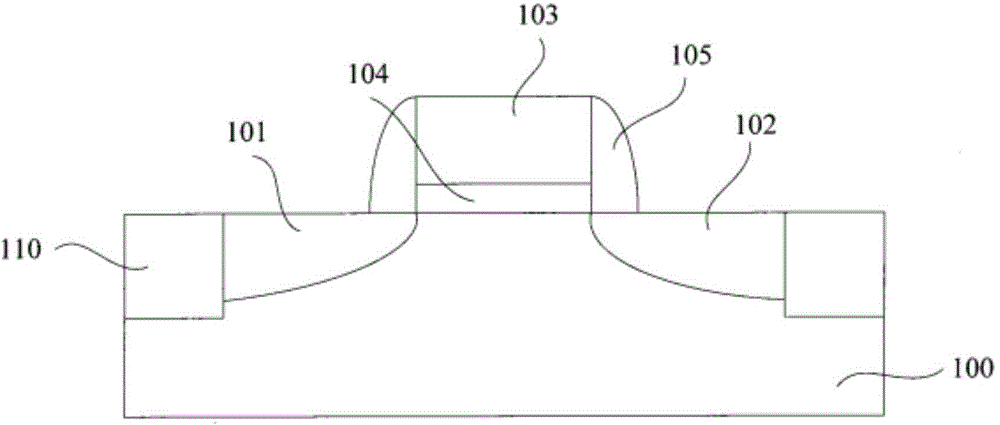

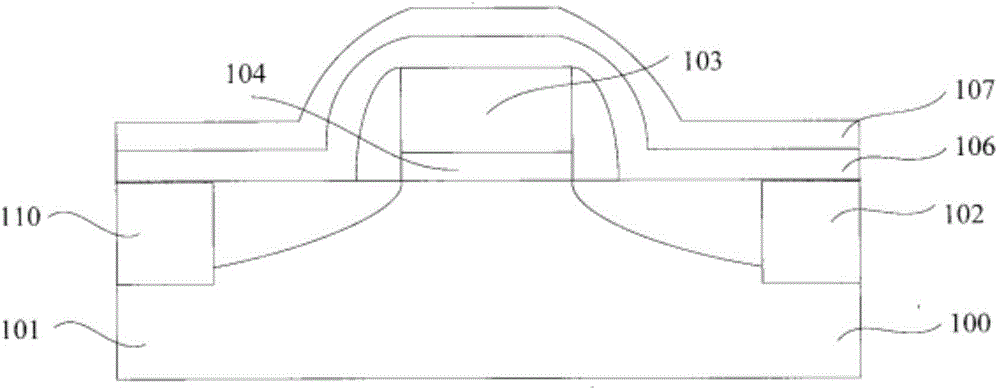

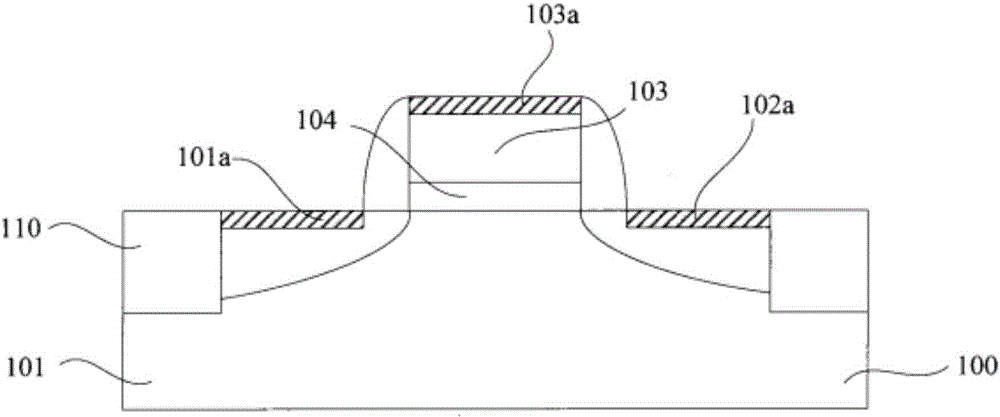

[0031] Embodiments of the present invention use the existing commonly used Ni as the material for forming metal silicides, and are based on a two-step annealing process, combining Figure 4 to Figure 5 , to explain the improvement of the technical solution of the present invention in detail, but the technical solution of the present invention is not limited thereto.

[0032] The method for forming the salicide of this embodiment includes the following steps:

[0033] Step 1, such as Figure 4 As shown, a semiconductor substrate 11 is provided. The surface of the substrate 11 has a silicon region, and the silicon region includes a gate 12 of a MOS transistor and a source region 13 and a drain region 14 formed in the substrate 11 on both sides of the gate 12 . The gate 12 includes a gate dielectric layer 121 , a gate electrode layer 122 , and spacers 123 formed on both sides of the gate dielectric layer and the gate electrode layer.

[0034] Before depositing the metal layer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com