Array substrate, production method thereof and display device

A technology of an array substrate and a manufacturing method, applied in the display field, can solve the problems affecting the conduction characteristics of TFT, surface roughness, etc., and achieve the effects of ensuring display quality, repairing damage, and improving electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

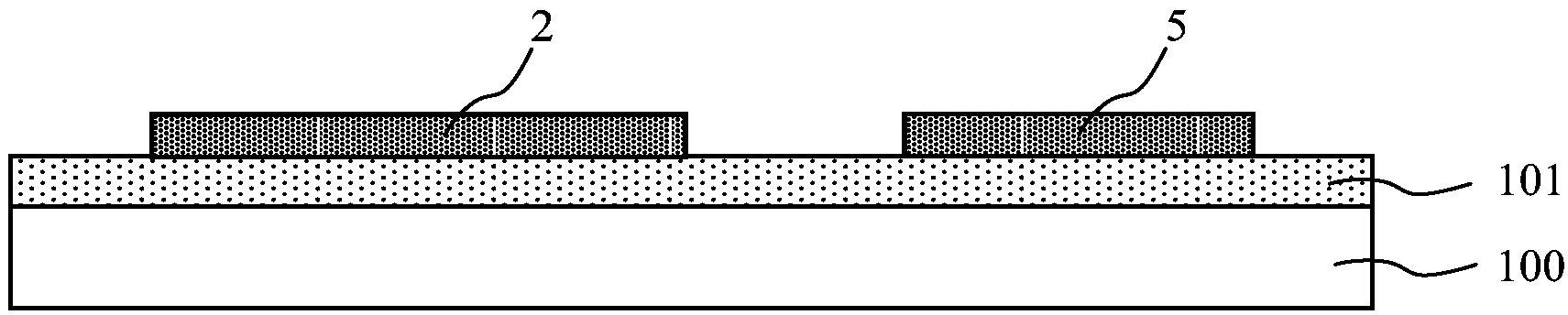

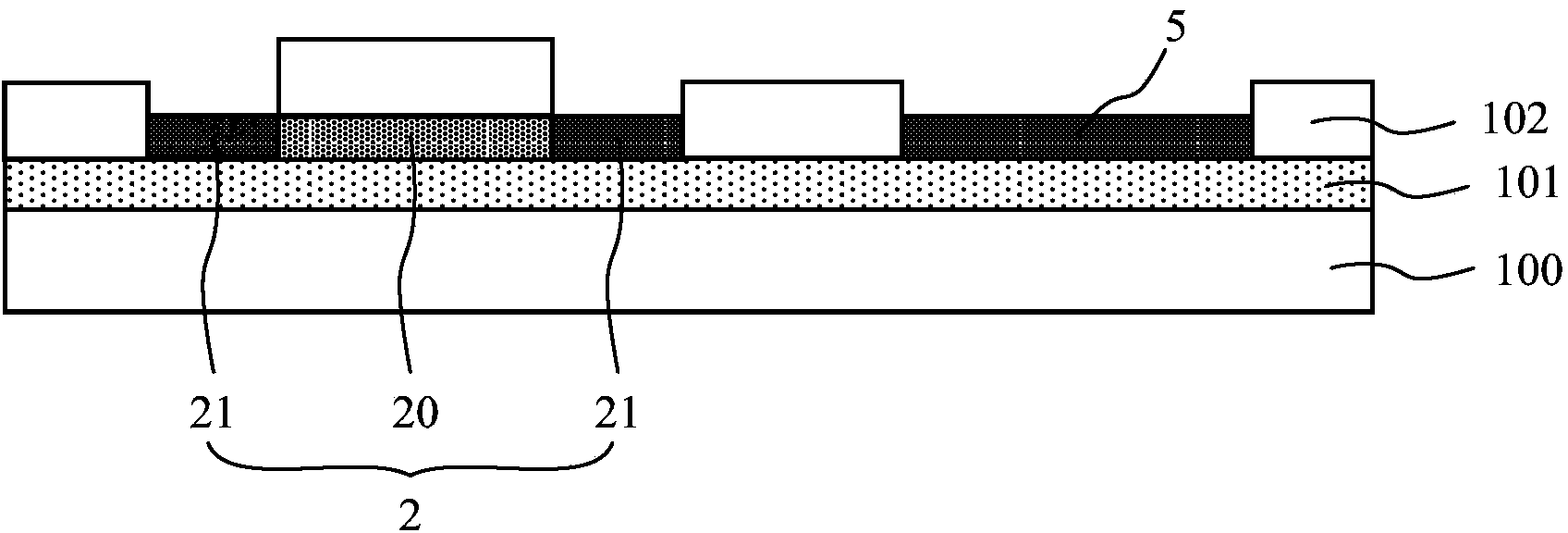

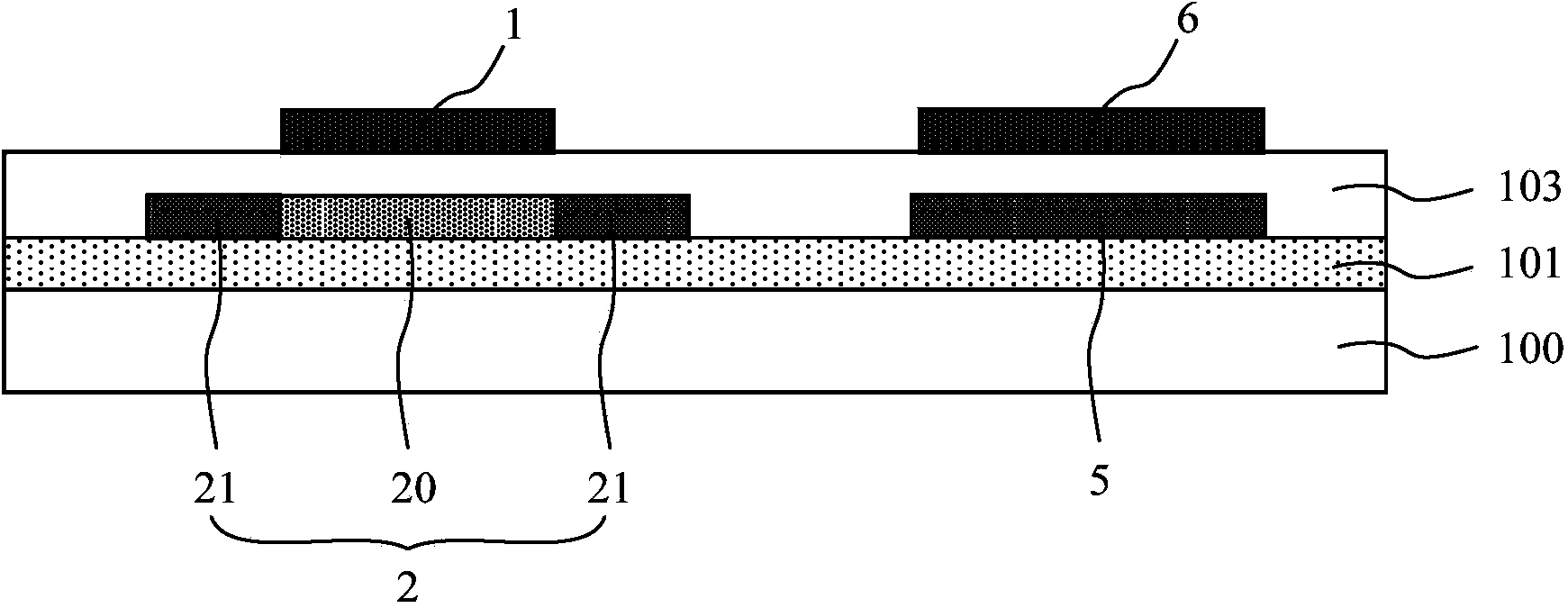

[0027] In the manufacturing process of the array substrate, the electrical connection between different conductive layers is generally completed by making insulating layer via holes, that is, different conductive layers are electrically contacted through the insulating layer via holes. When the array substrate includes thin film transistors, the gold half-electric contact between the source electrode, the drain electrode and the active layer pattern (specifically referring to the electrical contact between the source and drain metal and the semiconductor active layer) is realized through the insulating layer via holes, forming an insulating layer. In the etching process of the layer via hole, in order to ensure that the via hole is etched completely without residue, the active layer at the via hole will also be etched, resulting in rough surface of the active layer at the via hole, and the subsequent source When the electrode and the drain electrode are in contact with the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com