Offshore platform oil extraction electric submersible pump variable frequency driving system

An offshore platform, variable frequency drive technology, applied in the control system, motor generator control, AC motor control, etc., can solve the problems of poor harmonic filtering effect of passive filter, influence of platform power quality, low energy utilization efficiency, etc. , to achieve the effect of reducing total capacity requirements, reducing operation and maintenance work, and avoiding reactive power compensation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

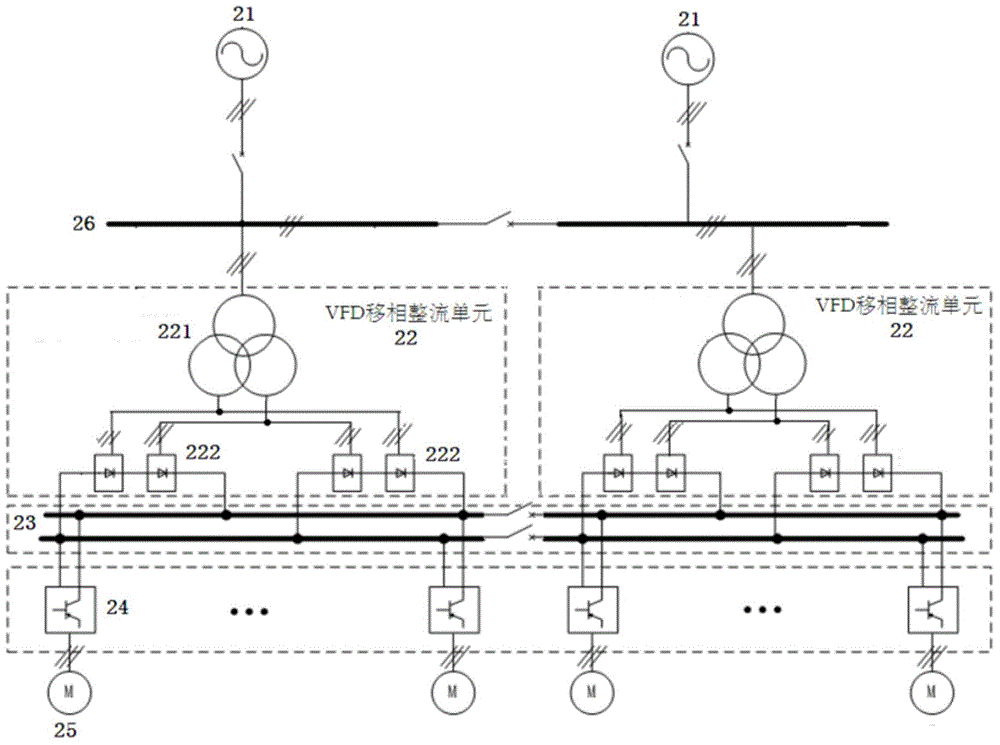

[0012] Such as figure 2 As shown, the variable frequency drive system of the electric submersible pump for offshore platform oil production of the present invention includes more than two offshore platform generators 21, more than one frequency converter (VFD) phase-shifting rectifier unit 22, and two public DC buses 23 arranged in parallel at intervals , several inverters 24 and electric submersible pump motors 25 with the same number as inverters 24; wherein, each frequency converter phase-shifting rectification unit 22 includes a phase-shifting step-down transformer 221 and more than two rectifiers 222; all offshore The platform generator 21 is connected to the input end of each phase-shifting step-down transformer 221 through an AC bus 26, and the output end of each phase-shifting step-down transformer 221 is connected in parallel to the output e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com