Compound synergistic herbicide and preparation technology thereof

A herbicide and water preparation technology, applied in the field of compound synergistic herbicides and their preparation, can solve problems such as poor quick-acting properties, and achieve the effects of making up for poor quick-acting properties, low price, and delaying drug resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

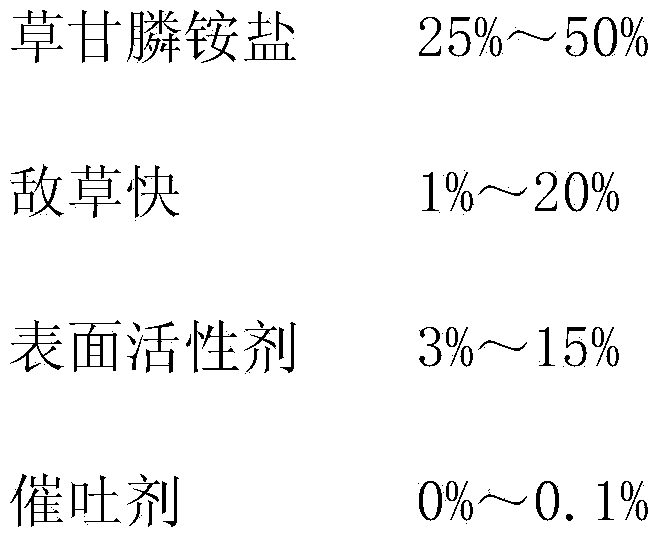

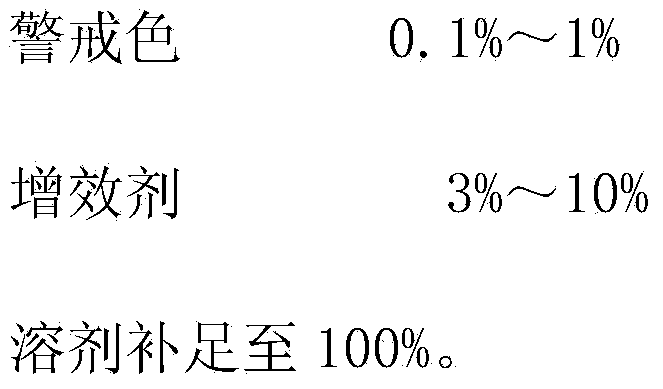

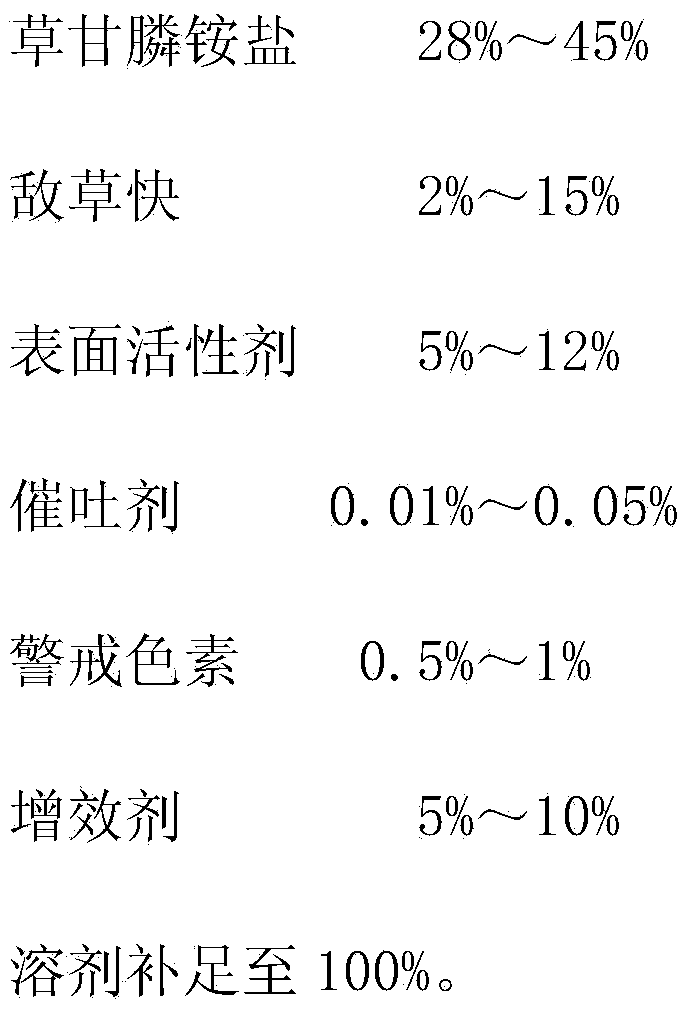

Method used

Image

Examples

Embodiment 1

[0042] Example 1 27% ammonium glyphosate · diquat aqueous solution

[0043] Step 1. Preparation of glyphosate ammonium salt: add 23% by weight glyphosate and 10% by mass water into the dispersion kettle, turn on the cooling water, control the temperature in the dispersion kettle at 10°C-60°C, and adjust the mixer Stirring speed is 50r / min, stir 20min, pass into the ammonia gas of 9.2% by weight to dispersion kettle, make glyphosate completely react and generate 25% glyphosate ammonium salt;

[0044] Step 2. Mix raw materials: keep turning on the cooling water, control the temperature in the dispersion kettle at 10°C-60°C, and continue to add 2% diquat, 15% sodium lauryl sulfate, and 0.1% triazole to the dispersion kettle Pyrimidinone, 1% carmine, 10% organic silicon, and water to make up to 100%, wherein the organic silicon is Sliwet L-722, adjust the stirring speed of the mixer to 50r / min, and stir for 30min; after the mixing is completed, the water agent is obtained; samplin...

Embodiment 2

[0045] Example 2 43% ammonium glyphosate · diquat aqueous solution

[0046] Step 1. Preparation of glyphosate ammonium salt: Add 25% by weight glyphosate and 15% by mass water into the dispersion kettle, turn on the cooling water, control the temperature in the dispersion kettle at 10°C-60°C, and adjust the mixer The stirring speed is 80r / min, stirring for 30min, feeding 10% ammonia by weight into the dispersion tank, so that the glyphosate is completely reacted to generate 28% glyphosate ammonium salt;

[0047] Step 2. Mix raw materials: keep turning on the cooling water, control the temperature in the dispersion kettle at 10°C-60°C, continue to add 15% diquat, 12% phenethylphenol polyoxyethylene ether, 0.05% Triquat to the dispersion kettle Pyrimidinone, 0.5% brilliant blue warning pigment, 9% pine ester-based vegetable oil, and water make up to 100%, adjust the stirring speed of the mixer to 80r / min, and stir for 50min; after the mixing is completed, the water agent is obta...

Embodiment 3

[0048] Example 3 37% ammonium glyphosate · diquat aqueous solution

[0049] Step 1. Preparation of glyphosate ammonium salt: Add 30% glyphosate by weight and 20% by mass water into the dispersion kettle, turn on the cooling water, control the temperature in the dispersion kettle at 10°C-60°C, and adjust the mixer The stirring speed is 70r / min, stirring for 40min, feeding 12% ammonia by weight to the dispersion tank, so that the glyphosate is completely reacted to generate 33% glyphosate ammonium salt;

[0050] Step 2. Mix raw materials: keep turning on the cooling water, control the temperature in the dispersion tank at 10°C-60°C, and continue to add 4% diquat, 10% fatty alcohol sodium sulfate, and 0.01% triazole pyrimidinone into the dispersion tank , 0.9% carmine warning pigment, 8% palm kernel oil fatty acid methyl ester, water make up to 100%, adjust the stirrer stirring speed to be 70r / min, stir 50min; Promptly get water agent after mixing; Sampling analysis, after passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com