Graphene stripping kettle, graphene production system and graphene production method

A production system and graphene technology, applied in the field of stripping kettle and graphene production system, can solve problems such as difficult shear stripping, complex process, structural defects, etc., to ensure controllability and repeatability, and high product repeatability , The effect of less structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The invention relates to a graphene stripping kettle, a graphene production system and a graphene production method.

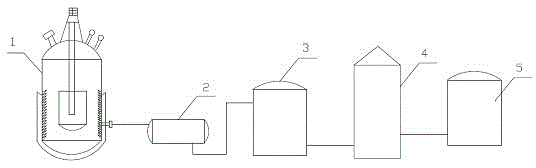

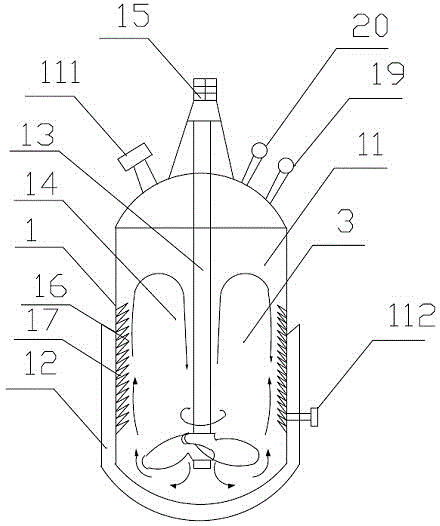

[0046] The graphene production system, such as figure 1 Shown, comprise graphene stripping kettle 1, storage tank 2, centrifuge 3, vacuum filtration device 4 and freeze-drying device 5 successively along process sequence; The product is discharged, the centrifuge 3 is used to centrifuge the upper layer suspension in the storage tank 2 to separate the exfoliated graphene and the unexfoliated graphite, and the vacuum filter device 4 is used to filter and wash the supernatant obtained after the centrifuge 3 is centrifuged , the freeze-drying device 5 is used for drying the graphene after vacuum filtration. Here, the discharge port 112 of the peeling kettle 1 is connected with the feed port of the storage tank 2, the discharge port of the storage tank 2 is connected with the feed port of the centrifuge 3, and the supernatant liquid discharge port of the ce...

Embodiment 2

[0054] As mentioned above, the tooth-shaped fixed shear blade 16 has less effect on the structure of graphene than the tapered shear blade 16 . On the basis of Embodiment 1, this embodiment has been improved. One of the differences between this embodiment and Embodiment 1 lies in the structure of the fixed shear blade 16 .

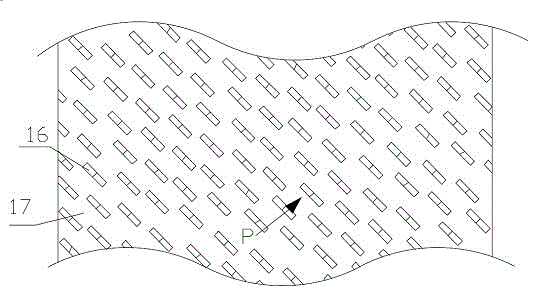

[0055] In the present embodiment, the zigzag fixed shear blade 16 is selected, and the two side end faces of each fixed shear blade 16 are perpendicular to its helical line, thereby greatly increasing the shearing effective area; meanwhile, in order to reduce the fixed shear The damage of the tooth tip of cutting blade 16 to the graphene structure, such as Figure 4 and Figure 5 As shown, the fixed shear blade 16 is designed as a hook knife, not only the end faces on both sides of each fixed shear blade 16 are perpendicular to the helix (P direction) where it is located, but also slightly away from the fixed shear blade 16 from the tip of the fixed shea...

Embodiment 3

[0058] In order to make the graphite layer be sheared in parallel, the difference from Example 1 is that, as Figure 6 As shown, in the present embodiment, the radial flow type stirring paddle 14 is selected, and its characteristic is that the main discharge direction is perpendicular to the axial direction of the rotating shaft 13, that is, the stirring paddle 14 mainly discharges liquid in the radial direction, and the discharged liquid is then pasted Combine the inner wall surface of the still body, respectively flow to the top of the inner wall area of the still body 11 in a spiral ascending manner, and flow to the below of the inner wall area of the kettle body 11 in a spiral descending manner, as Figure 6 shown. For the graphite layer to be sheared to the greatest extent, reduce the impact force, and then reduce the probability of being crushed by impact, set the upper fixed shear blade 16-1 and the lower fixed shear blade 16-2 respectively; the upper fixed shear bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com