A vertical rotary gravity separation oil separation tank

A gravity separation and rotary technology, which is applied in the direction of liquid separation, separation method, grease/oily substance/floating matter removal device, etc., can solve the problem of reduced effective volume in the tank, long residence time, poor heat tracing and heat transfer effect To achieve the effect of avoiding complex flow field and "dead zone" of water flow, increasing gravity separation time and improving oil separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention is described in further detail:

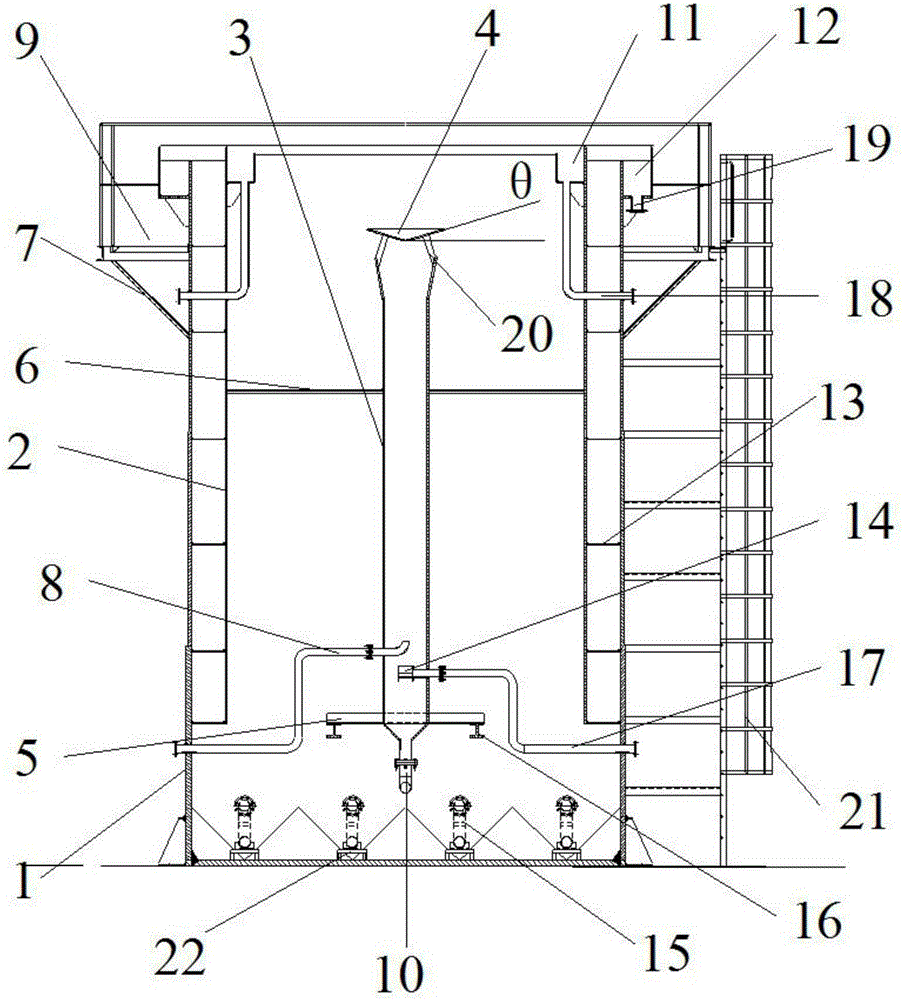

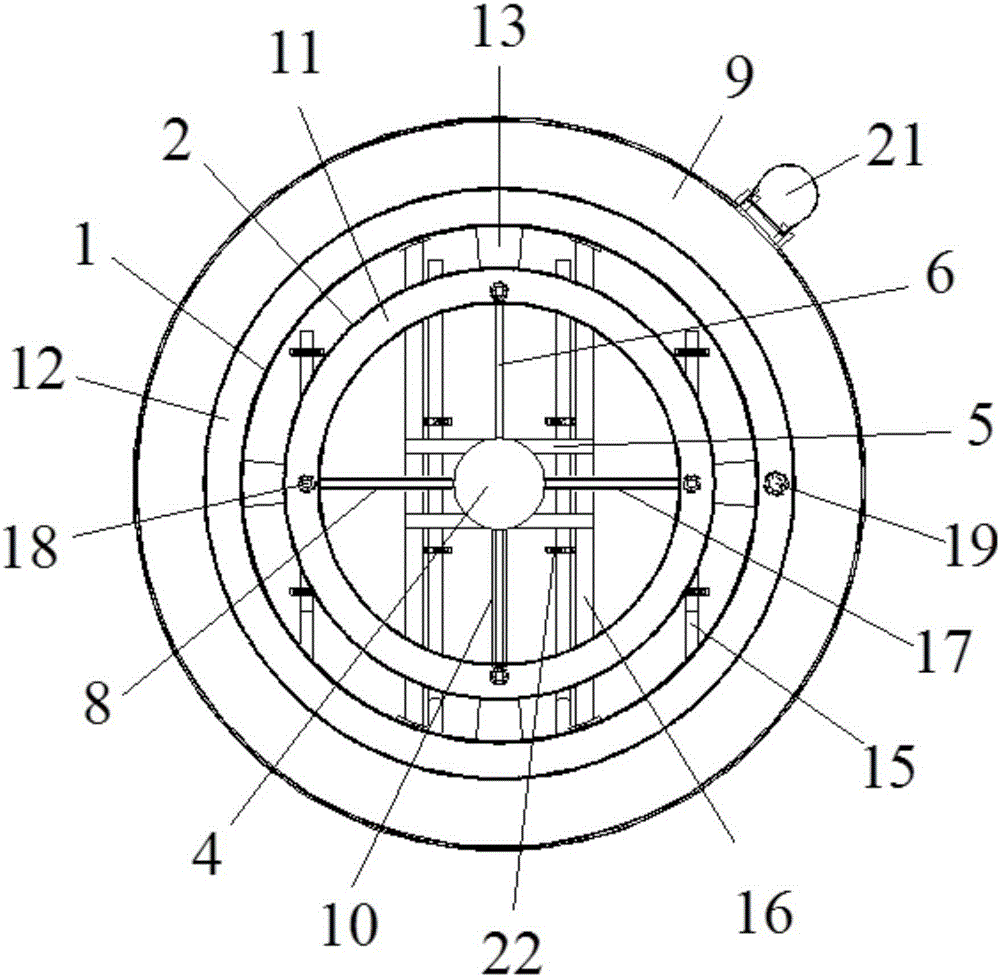

[0024] Such as figure 1 As shown, the vertical rotary gravity separation oil separation tank of the present invention includes an outer cylinder 1, an inner cylinder 2 is arranged inside the outer cylinder 1, and the tank wall of the outer cylinder 1 and the inner cylinder 2 is separated by 50 cm. Mounting and positioning plates 13 evenly distributed at 90° are arranged from bottom to top, and the bottom of the inner cylinder body 2 is 2.0m above the ground, and is fixedly supported by No. 2 H-shaped steel brackets 16 . The inner cavity of the inner cylinder body 2 is provided with a central water inlet tube 3, the inner diameter of which is 60cm, and is fixedly supported by the No. 1 H-shaped steel bracket 5, and the No. 1 H-shaped steel bracket spans and is fixed on the No. 2 H-shaped steel bracket 16 , there is a supporting angle iron 6 between the inner cylinder body 2 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com