Anionic clean fracturing fluid

A clean fracturing fluid, anionic technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems affecting the viscoelasticity of fracturing fluid, high toxicity and irritation, harsh preparation conditions, etc., and achieve adsorption Small, low formation damage, simple configuration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

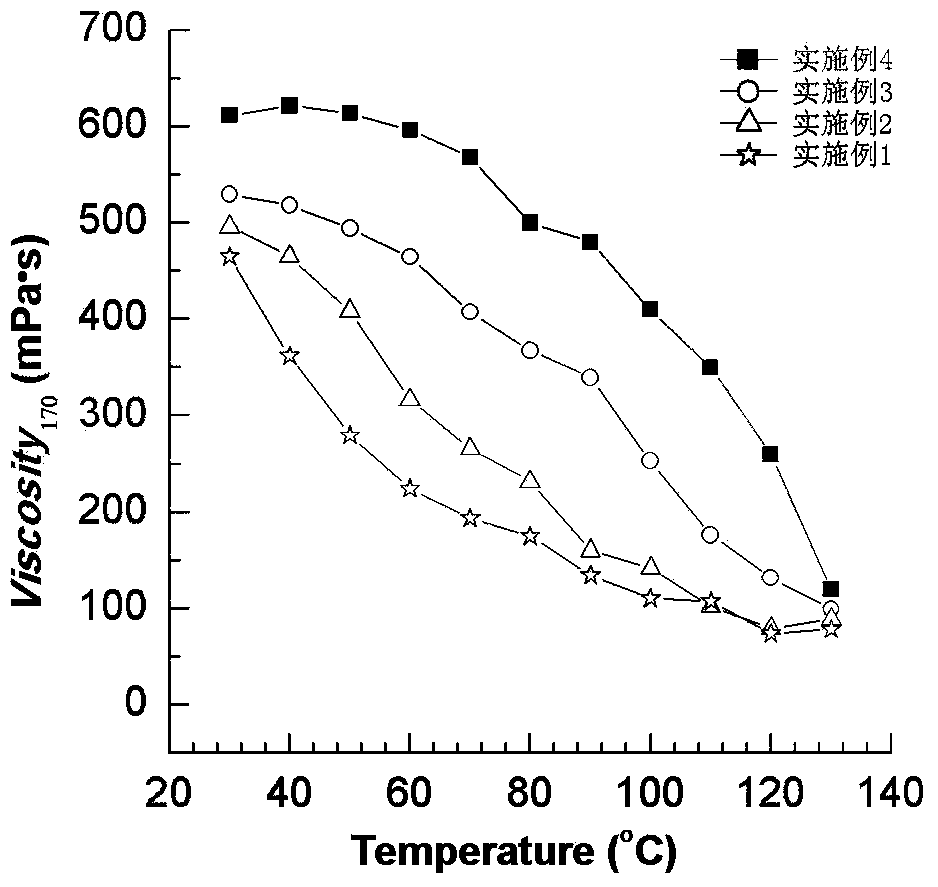

[0023] Anionic clean fracturing fluid includes the following ingredients: sodium stearate 2%, potassium erucate 2%, N 1 ,N 1 ,N 1 ,N 2 ,N 2 ,N 2 - Hexamethylpropyldiammonium bromide 1.5%, fumed silica 0.5%, water 93.5%. Its viscosity-temperature performance can be seen in figure 1 , as the temperature increases, the viscosity of the fracturing fluid decreases continuously, but at 120 degrees Celsius, 170s -1 The shear viscosity can still be maintained at about 50mPa.s, fully meeting the needs of oil and gas field fracturing operations.

Embodiment 2

[0025] Anionic clean fracturing fluid includes the following ingredients: Potassium behenate 4%, N 1 ,N 1 ,N 2 ,N 2 -Tetramethyl-N 1 ,N 2 - Dibenzylhexyl diammonium bromide 2.5%, N 1 ,N 1 ,N 1 ,N 2 ,N 2 ,N 2 - 0.5% of hexamethylpropyl diammonium bromide, 0.8% of barium sulfate, and the balance is water. Its viscosity-temperature performance can be seen in figure 1 , 170s at room temperature -1 Under the shear viscosity is about 490mPa.s, when the temperature rises to 120 degrees Celsius, 170s -1 The shear viscosity remains above 50mPa.s.

Embodiment 3

[0027] Anionic clean fracturing fluid includes the following ingredients: peanut sodium 2.5%, potassium stearate 2.5%, potassium behenate 0.5%, N 1 ,N 1 ,N 2 ,N 2 -Tetramethyl-N 1 ,N 2 - Diethylhexyl diammonium chloride 2%, N 1 ,N 1 ,N 1 ,N 2 ,N 2 ,N 2 - Hexamethylethyldiammonium bromide, kaolin 0.3%, balance water. Its viscosity-temperature performance can be seen in figure 1 , 170s at the start -1 Under the shear viscosity is about 530mPa.s, when the temperature rises to 120 degrees Celsius 170s -1 Under the shear viscosity is still maintained at about 50mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com