Colored fiber dual-component blended yarn manufacturing method

A blended yarn and colored fiber technology, which is applied in the field of yarn manufacturing, can solve problems such as high production costs and affecting the production of multi-component blended yarns, and achieve solutions to unstable factors and waste, rich color types, increased The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

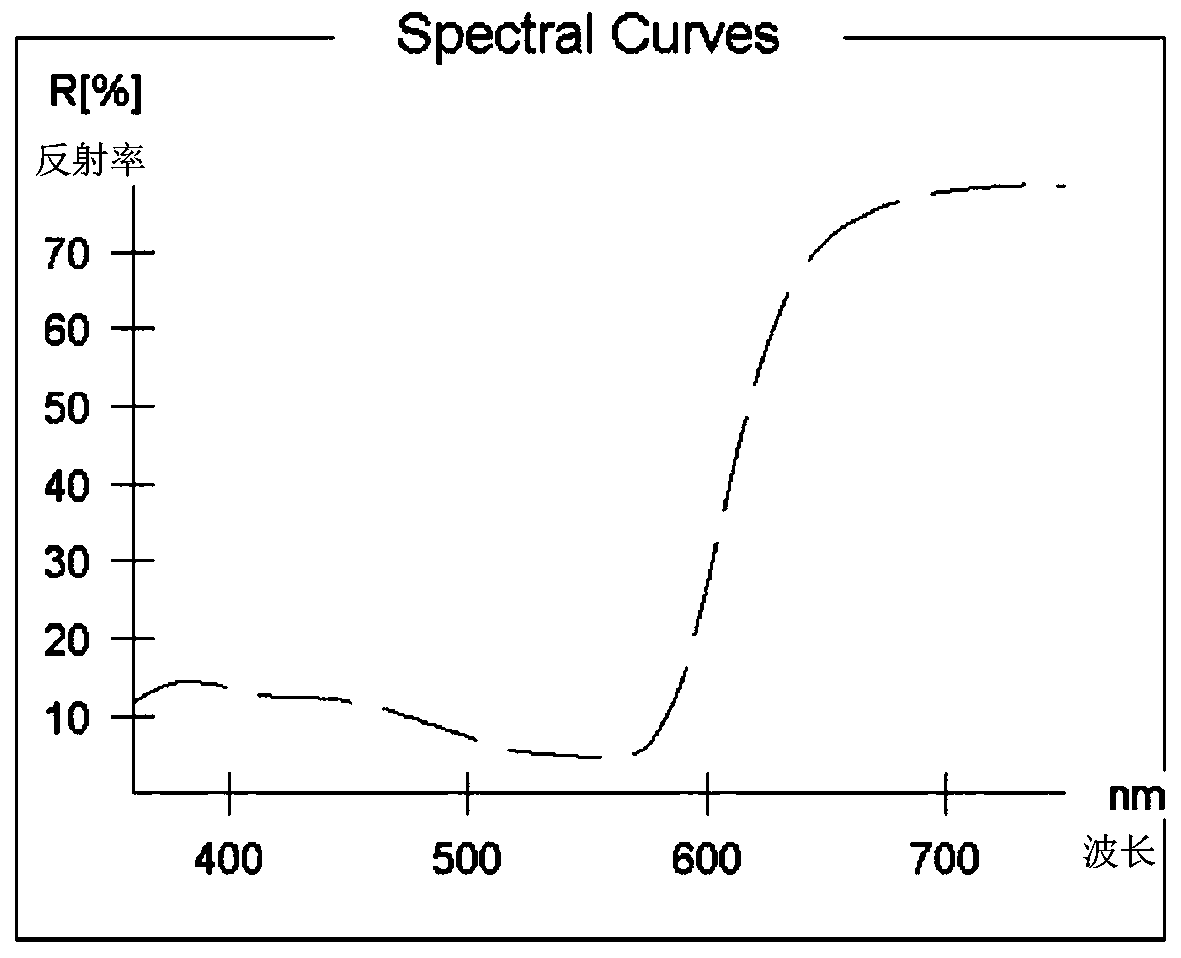

[0042] According to red: yellow=1:1, regenerated cellulose staple fiber: the ratio of polyester staple fiber=7:3 carries out loose fiber mixed color matching, weighs respectively red regenerated cellulose staple fiber 350kg, yellow regenerated cellulose staple fiber 350kg, 150kg of red polyester staple fiber and 150kg of yellow polyester staple fiber are fed into the opening and cleaning equipment for preliminary opening and mixing, and then processed into cotton laps and then fed into the A186 type flat carding machine. The weight is 350 / m; after the carding machine is carded and bundled, it becomes a raw sliver with a certain degree of mixing, and the fixed weight is 20g / 5m. The draw frame selects the second draw frame to obtain the cooked sliver, and the fixed weight of the cooked sliver is 20g / 5m. Cooked sliver obtains roving through 8 times drafting on roving frame, and fixed weight is 500tex. The roving is drafted 27 times on the spinning frame to obtain a spun yarn wit...

Embodiment 2

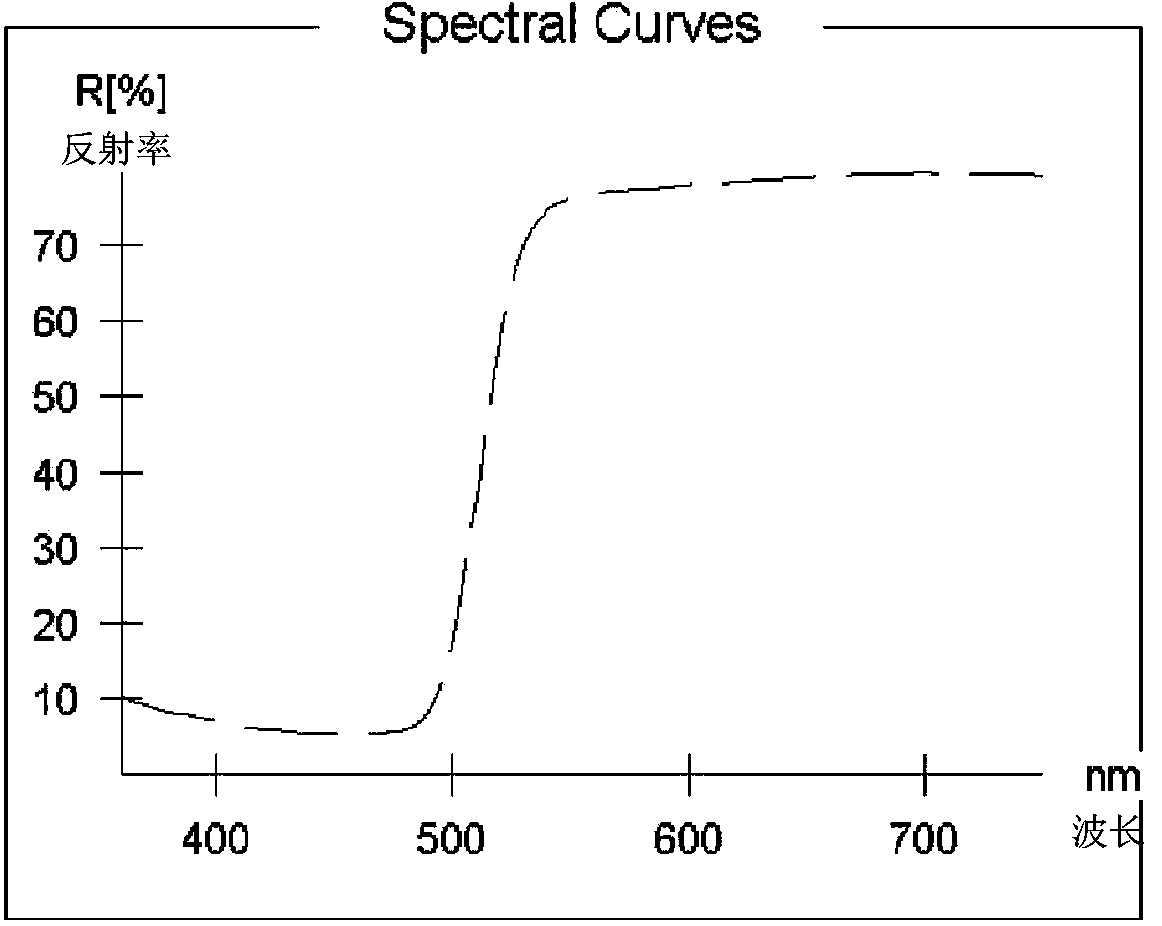

[0044] According to the ratio of blue: white = 2:3, regenerated cellulose staple fiber: polyester staple fiber = 1:1, carry out loose fiber mixed color matching, weigh blue regenerated cellulose staple fiber 200kg, white regenerated cellulose staple fiber respectively 300kg, 200kg of blue polyester staple fiber, and 300kg of white polyester staple fiber are fed into the opening and cleaning equipment for preliminary opening and mixing, and then processed into laps and then fed into the A186 flat carding machine. The fixed weight of the lap is 450 / m; after carding and bundling by the carding machine, it becomes a raw sliver with a certain degree of mixing, and the fixed weight is 20g / 5m. The draw frame selects the second draw frame to obtain the cooked sliver, and the fixed weight of the cooked sliver is 20g / 5m. The cooked sliver is directly fed into the rotor spinning machine to obtain spun yarn with a fineness of 59tex (10 lbs)-light blue (Lab value L*:62.1; a*:-12.88; b*:-23...

Embodiment 3

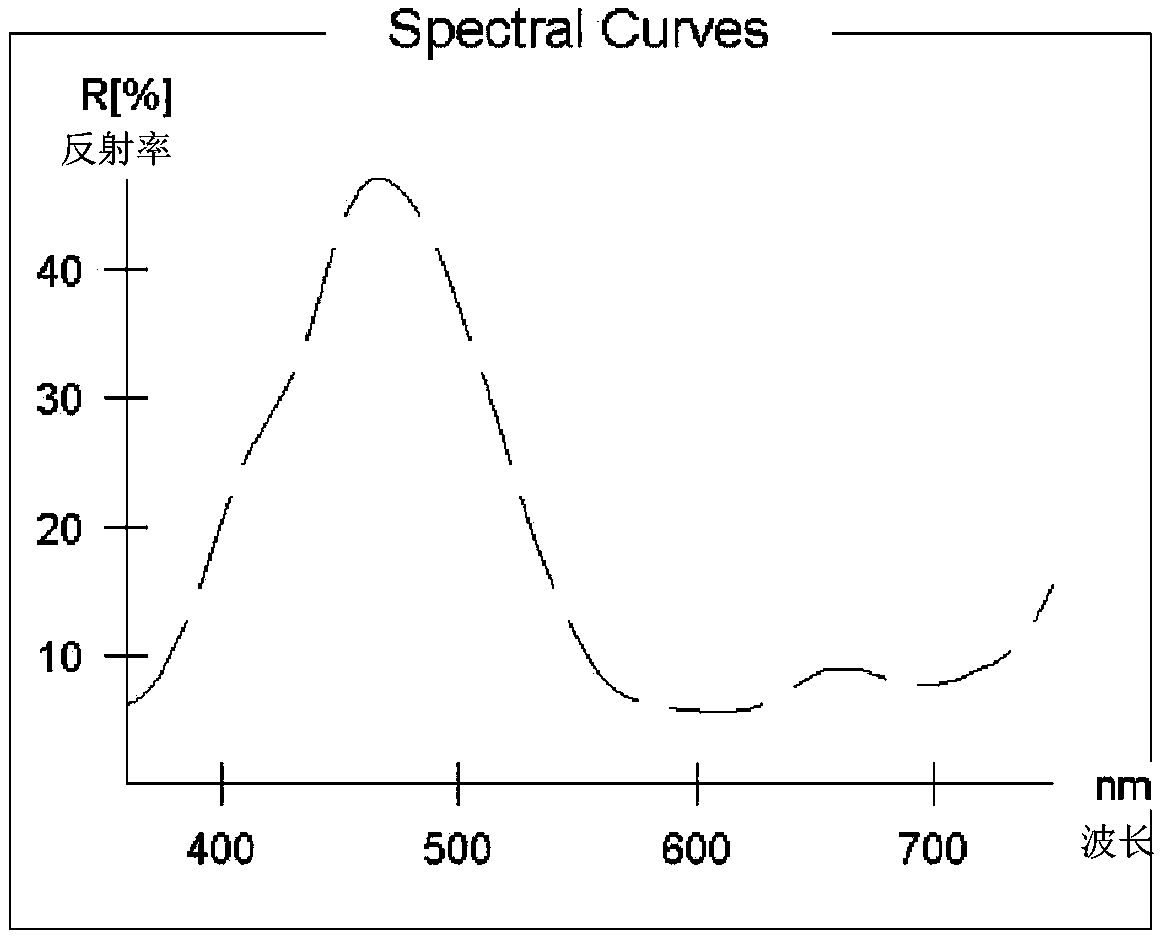

[0046] Red, yellow and white regenerated cellulose staple fibers and red, yellow and white polyester staple fibers are respectively subjected to the processes of opening and cleaning, carding and pre-drawing to obtain single-color cooked sliver with a fixed weight of 20g / 5m. According to the ratio of red: yellow: white = 1:1:2, regenerated cellulose staple fiber: polyester staple fiber = 1:1, carry out mixed color matching drawing, and take 1 red regenerated cellulose cooked strip and yellow regenerated cellulose respectively. 1 cooked stick, 2 white regenerated cellulose cooked sticks, 1 red polyester cooked stick, 1 yellow polyester cooked stick, 2 white polyester cooked sticks, a total of 8 cooked sticks, and then 2 times of merging , to obtain blended cooked sliver, the blended cooked sliver fixed weight is 20g / 5m. The blended cooked sliver is drafted 8 times on the roving frame to obtain a roving with a fixed weight of 500tex; the roving is drawn 27 times on the spinning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com