A high-performance steel bar

A high-performance, reinforced technology, applied in the direction of structural elements, building components, and other household appliances, can solve the problems of weak oxidation resistance of the aluminum outer protective layer, unfavorable concrete strength, and low concrete bonding force, so as to improve the grip strength , Guaranteed service life, improved bonding strength and anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

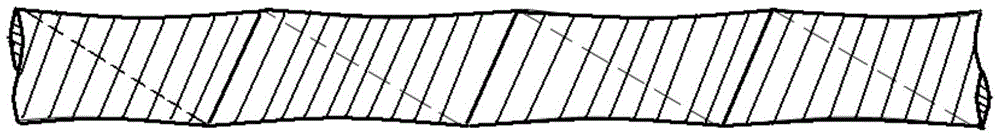

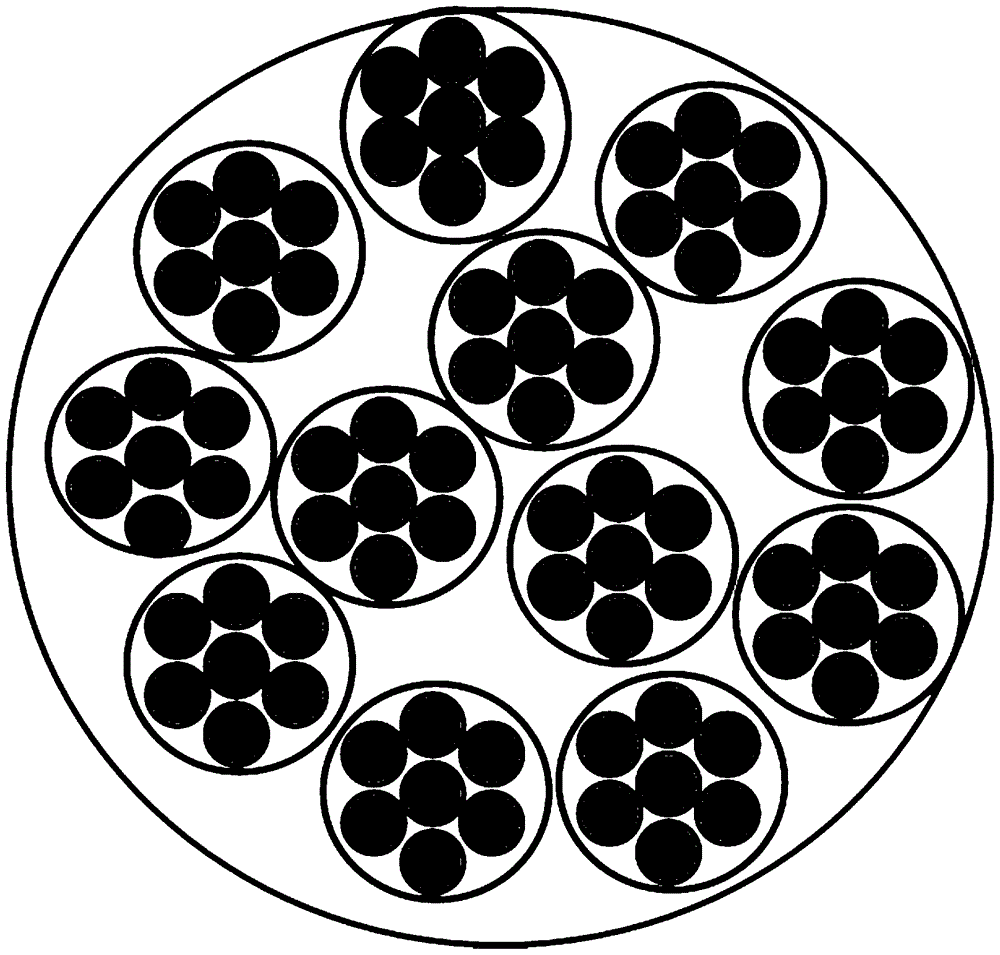

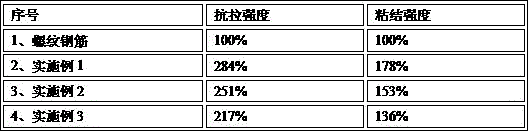

[0025] Embodiment 1, select the wire rod whose steel type is 72A to undergo pickling, water washing, saponification treatment, drawing, and annealing heat treatment to obtain a steel wire with a diameter of 0.9 mm; a steel wire with a diameter of 0.9 mm is copper-plated and cold-drawn to obtain a diameter of 0.2 mm. mm fine steel wire, copper layer thickness = 25um; unidirectionally twist 5 copper-plated fine steel wires into steel strands with a lay distance of 2.8mm, and then double-direction alternate and superimposed twisting of multiple strands of steel strands to form a nominal diameter of 6mm high performance steel bars.

Embodiment 2

[0026] Embodiment 2, select the wire rod whose steel grade is 72A to undergo pickling, water washing, saponification treatment, drawing, and annealing heat treatment to obtain a steel wire with a diameter of 1.0 mm; a steel wire with a diameter of 1.0 mm is copper-plated and cold-drawn to obtain a diameter of 0.22 mm fine steel wire, copper layer thickness = 30um; 7 copper-plated fine steel wires are unidirectionally twisted into a steel strand with a lay distance of 3.1mm, and then the multi-strand steel strands are bidirectionally interacted and superimposed to form a nominal diameter of 10mm high performance steel bars.

Embodiment 3

[0027] Embodiment 3, select the wire rod whose steel grade is 72A to undergo pickling, water washing, saponification treatment, drawing, and annealing heat treatment to obtain a steel wire with a diameter of 1.1 mm; the steel wire with a diameter of 1.1 mm is copper-plated and cold-drawn to obtain a diameter of 0.25 mm. mm fine steel wire, copper layer thickness = 35um; unidirectionally twist 9 copper-plated fine steel wires into a steel strand with a lay length of 3.5mm, and then double-cross the multi-strand steel strands, superimposed and twisted to form an equivalent diameter 20mm high-performance steel bars.

[0028] The embodiments of the present invention are only to briefly illustrate its advantages and characteristics, but are not limited to the specific descriptions of the embodiments (such as material, coating thickness, lay length, number of strands of steel wire bundles, etc.), and those skilled in the relevant fields are in the claims Various adjustments made wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com