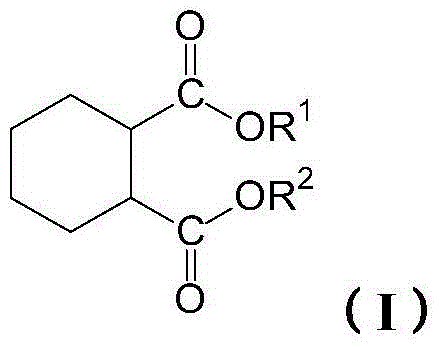

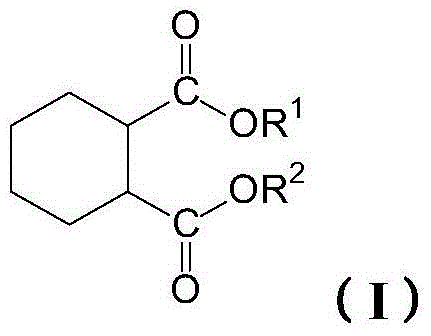

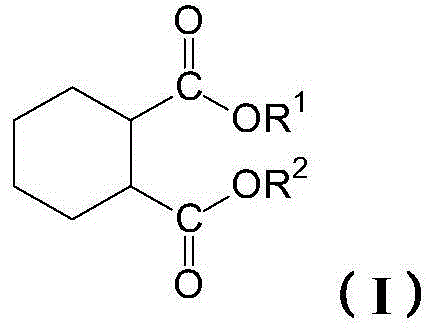

Thermoplastic polyurethanes composition and preparation processes thereof

A technology of thermoplastic polyurethane and composition, which is applied in the field of thermoplastic polyurethane composition, can solve the problems of increased abrasion, not mentioned alkyl cyclohexanedicarboxylate, etc., and achieve the effect of lowering the glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] Example 1: Polyether-based TPU compositions containing different additives prepared by "one-step" reactive extrusion.

[0105] Sample 1.1: Process 480.0 g of diphenylmethane 4,4'-diisocyanate (available from BASF's MDI, hereinafter abbreviated as "MDI"), 101.5g of 1,4-butanediol (BDO purchased from BASF, the same below) and 800.0g polytetrahydrofuran (purchased from BASF's BDO) with a number average molecular weight of 1000g / mol PTHF 1000, the same below) and 13.9 g of pentaerythritol tetrakis (3-(3,5-bis(1,1-dimethylethyl)-4-hydroxyphenyl) propionate) and 3, 3'-bis(3,5-di-tert-butyl-4-hydroxyphenyl)-N,N'-hexamethylenebispropionamide (purchased from BASF 1125) in a 1:1 mixture. In this process, all components except the MDI were preheated to 165° C. and fed into the first barrel of a ZSK 58 twin-screw extruder from Werner & Pfleiderer. Subsequently, the MDI preheated to 65° C. was put into the first barrel of the extruder. The rotational speed of the twin-screw sys...

Embodiment 2

[0117] Example 2: Polyether-based TPU compositions containing different additives and having substantially the same hardness prepared by the "one-step" belt transmission line method.

[0118] Sample 2.1: 500.0g of MDI, 90.9g of BDO, 1000.0g of PTHF1000 and 16.1g of 1125 blended and processed by belt transfer line method to obtain TPU granules. During this process, all components are preheated to 80°C and then thoroughly mixed in a stirred tank. When the reaction mixture reaches 90 to 95°C, it is poured on a continuous conveyor belt at 130 to 170°C and forms a TPU sheet on the belt after 5 to 15 minutes. Continuously produced TPU boards are crushed and homogenized in a crushing and homogenizing device with a terminal. The homogenized mass is then melted in a single-screw extruder with a zone temperature of 170°C to 230°C and finally pelletized by means of an underwater pelletizer.

[0119] Sample 2.2: The preparation of sample 2.1 was repeated, except that 2.4 g of the lubr...

Embodiment 3

[0129] Example 3: Polyether-based TPU compositions containing different additives prepared by the "two-step" method.

[0130] Sample 3.1: 630.0g of MDI, 180.6g of 1,6-hexanediol (HDO purchased from BASF), 1000.0g of PTHF 1000 and 9.1g of 1125 mixed and processed by the same belt transfer line method as sample 2.1 to obtain TPU granules.

[0131] Sample 3.2: 533.5g of MDI, 135.0g of HDO, 1000.0g of PTHF 1000 and 8.4g of 1125 mixed and processed by the same belt transfer line method as sample 2.1 to obtain TPU granules.

[0132] Sample 3.3: 1910.0 g of sample 3.1 were preheated at 120° C. for 2 hours, then 90.0 g (4.5% by weight) of DINCH were thoroughly mixed with the hot granules. The mixture was then placed in a closed container and annealed at 80 °C for 20 h. The DINCH-containing TPU pellets are then cooled and ready for injection molding.

[0133] Sample 3.4: 1910.0 g of sample 3.1 was preheated at 120° C. for 2 hours, and then 90.0 g (4.5% by weight, based on total T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molar mass | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com