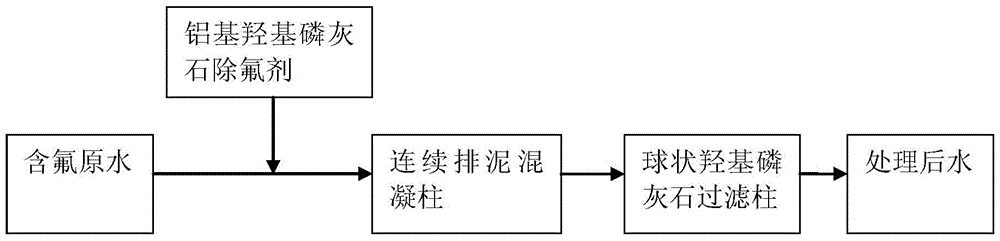

A compound drinking water defluoridation process

A drinking water and process technology, applied in the direction of water pollutants, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of short running time of equipment, less practical application, secondary pollution, etc., to ensure the turbidity of effluent water , Extensive practicability, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1, if the fluorine content of raw water is 3.16mg / L, the treatment process is as follows:

[0018] (1) Add 220ppm of composite hydroxyaluminum phosphorous ash defluoridation agent in the water inlet;

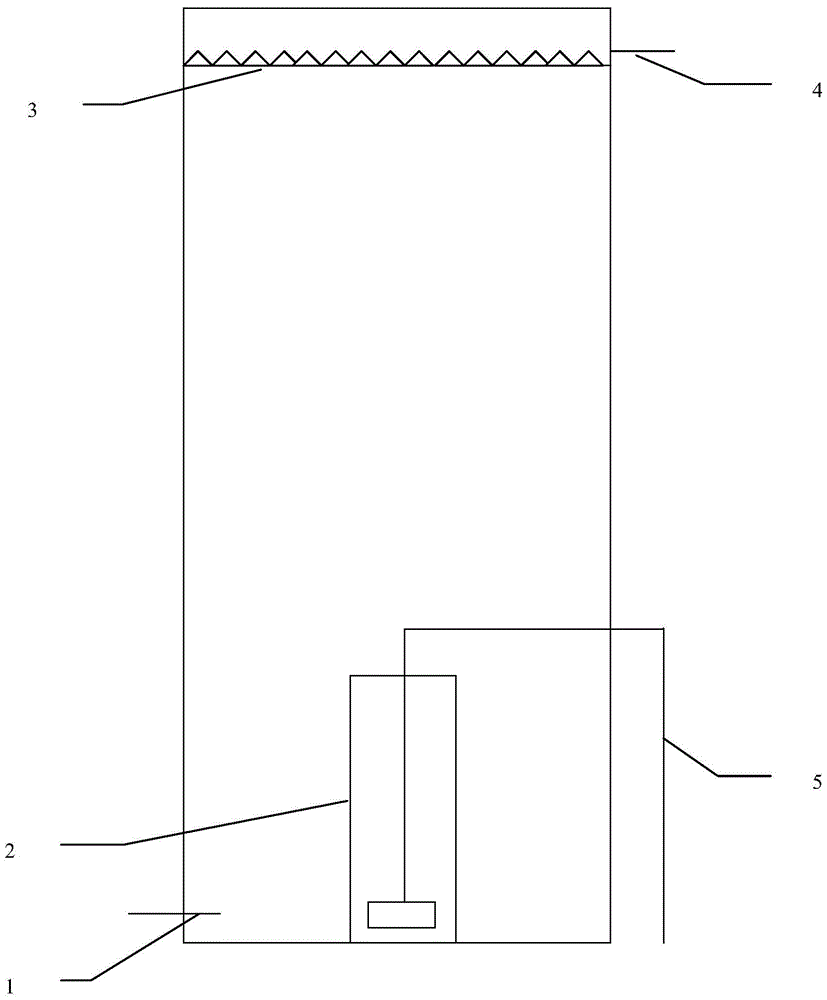

[0019] (2) The coagulation reaction occurs in a coagulation column with a diameter of 200mm and a height of 3.5m, and a fan-shaped static settling area accounting for 1 / 5 of the area and a height of 80mm is isolated on the side of the coagulation column for drainage. For mud, adjust the amount of mud discharge through the cut-off valve, so that the height of the floc is kept at 1.5m, and the rising flow rate of the coagulation column is 4m / hour;

[0020] (4) The effluent of the coagulation column flows through the spherical hydroxyapatite adsorption filter column with a diameter of 200mm and a height of 1.5m for filtration. The height of the spherical hydroxyapatite filter layer is 0.5m and the filtration rate is 4m / hour ;

[0021] (5) Backwash the spherical ...

Embodiment 2

[0023] Embodiment 2, if the fluorine content of raw water is 2.3mg / L, the treatment process is as follows:

[0024] (1) Add 150ppm of composite hydroxyaluminum phosphorous ash defluoridation agent in the water inlet pipe;

[0025] (2) Introduce the coagulation reaction in a coagulation column with a diameter of 200mm and a height of 3.5m, and use a partition to isolate a fan-shaped static settling area accounting for about 1 / 5 of the area and a height of 80mm on the side of the coagulation column. For mud discharge, adjust the amount of mud discharge through the stop valve so that the height of the floc is kept at 1.5m, and the rising flow rate of the coagulation column is 5m / hour;

[0026] (4) The effluent of the coagulation column flows through a spherical hydroxyapatite adsorption filter column with a diameter of 200mm and a height of 1.5m. The height of the spherical hydroxyapatite filter layer is 0.5m, and the filtration rate is 5m / hour;

[0027] (5) Backwash the spheric...

Embodiment 3

[0029] Embodiment 3, if the fluorine content of the raw water is 1.6 mg / L, the treatment process is as follows:

[0030] (1) Add 60ppm of composite hydroxyaluminum phosphorous ash defluoridation agent in the water inlet;

[0031] (2) Introduce the coagulation reaction in a coagulation column with a diameter of 200mm and a height of 3.5m, and use a partition to isolate a fan-shaped static settling area accounting for about 1 / 5 of the area and a height of 80mm on the side of the coagulation column. For mud discharge, adjust the amount of mud discharge with the stop valve so that the height of the floc is kept at 1.5m, and the rising flow rate of the coagulation column is 6m / hour;

[0032] (4) The effluent of the coagulation column flows through a spherical hydroxyapatite adsorption filter column with a diameter of 200mm and a height of 1.5m. The height of the spherical hydroxyapatite filter layer is 0.5m, and the filtration rate is 6m / hour;

[0033] (5) Backwash the spherical h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com