Method for converting calcium alkylbenzene sulfonate into sodium alkyl benzene sulfonate

A technology of calcium alkyl benzene sulfonate and sodium alkyl benzene sulfonate, applied in the fields of sulfonate preparation, organic chemistry, etc., can solve the problems such as the inability to effectively remove calcium and calcium alkyl benzene sulfonate, and the inability to remove calcium ions, Achieve the effect of easy separation and purification, easy operation and guaranteed purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

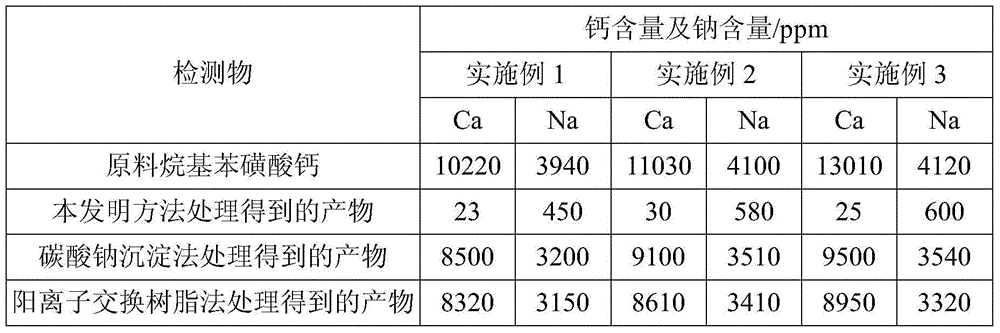

[0028] The present embodiment provides a kind of method that calcium alkylbenzene sulfonate is converted into sodium alkylbenzene sulfonate, comprising the following steps:

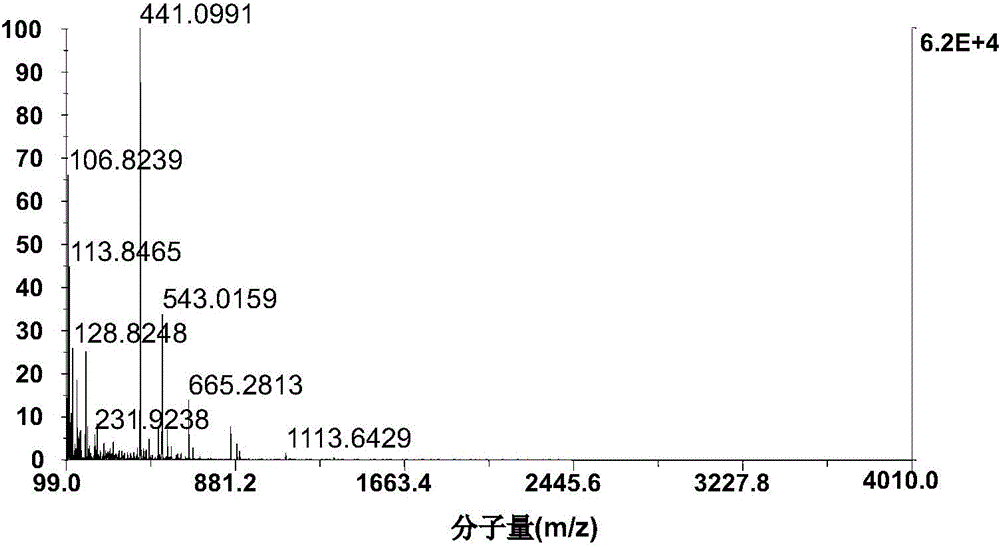

[0029] Place a 500mL single-necked flask in a water bath with a magnetic stirrer and heating function, and successively add 0.7mL of 30% sodium hydroxide solution and 2.38g of calcium alkylbenzenesulfonate into the single-necked flask. Calcium benzenesulfonate is a mixture, its alkyl chain length is C 16 -C 30 (take C 26 The molecular weight of the calcium alkylbenzenesulfonate is used as the average molecular weight of the calcium alkylbenzenesulfonate, and the molar mass is 544.39g / mol), and the stirring is started and carbon dioxide gas is introduced into the single-necked flask at a speed of 10mL / min, and the controlled reaction temperature is 30°C;

[0030] Keep the reaction for 3 hours, it can be seen that there is precipitation in the reaction solution, the pH of the test solution is 8, and the r...

Embodiment 2

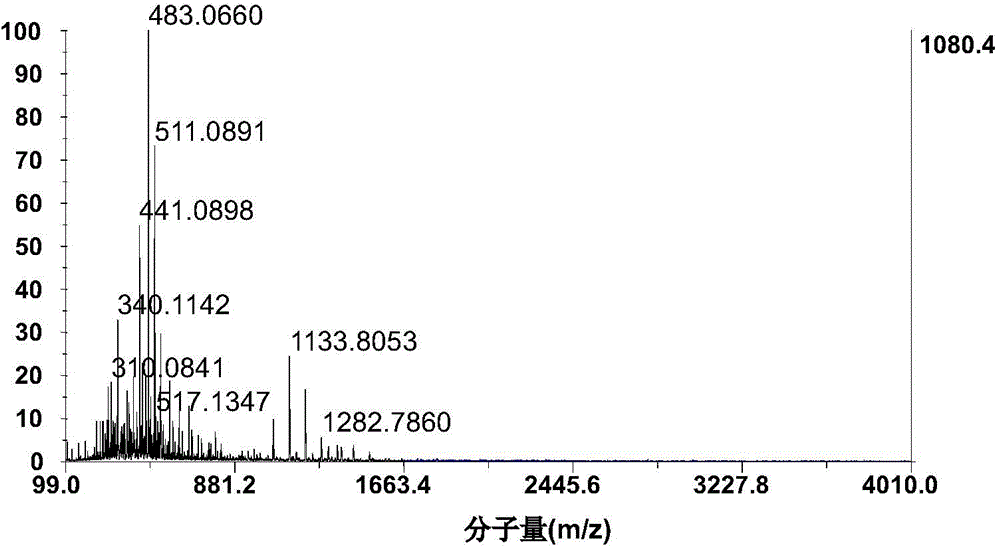

[0036] The present embodiment provides a kind of method that calcium alkylbenzene sulfonate is converted into sodium alkylbenzene sulfonate, comprising the following steps:

[0037] Place a 500mL single-necked flask in a water bath with a magnetic stirrer and a heating function, and add 1.2mL of 10% sodium hydroxide solution and 0.65g of calcium alkylbenzenesulfonate into the single-necked flask. Calcium sulfonate is a mixture with an alkyl chain length of C 16 -C 30 (take C 26 The molecular weight of the calcium alkylbenzenesulfonate is used as the average molecular weight of the calcium alkylbenzenesulfonate, and the molar mass is 544.39g / mol), and the stirring is started and carbon dioxide gas is passed into the single-necked flask at a speed of 30mL / min, and the controlled reaction temperature is 60°C;

[0038] Keep the reaction for 2 hours, it can be seen that there is precipitation in the reaction solution, the pH of the test solution is 7, and the reaction is stopped;...

Embodiment 3

[0044] The present embodiment provides a kind of method that calcium alkylbenzene sulfonate is converted into sodium alkylbenzene sulfonate, comprising the following steps:

[0045] Place a 500mL single-necked flask in a water bath with a magnetic stirrer and a heating function, and add 0.76mL of 25% sodium hydroxide solution and 1.3g of calcium alkylbenzenesulfonate into the single-necked flask. Calcium sulfonate is a mixture with an alkyl chain length of C 16 -C 30 (take C 26The molecular weight of the calcium alkylbenzenesulfonate is the average molecular weight of the calcium alkylbenzenesulfonate, and the molar mass is 544.39g / mol), and the stirring is started and carbon dioxide gas is introduced at a speed of 15mL / min, and the controlled reaction temperature is 50°C;

[0046] Keep the reaction for 2.5 hours, it can be seen that there is precipitation in the reaction solution, the pH of the test solution is 8, and the reaction is stopped;

[0047] After cooling, use a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com