Color steel tile paint

A technology for color steel tiles and coatings, applied in the field of coatings, can solve problems such as affecting the service life, rusting of color steel tiles, easy aging and peeling of coatings, etc., and achieve the effects of prolonging service life, enhancing water resistance, and maintaining excellent gloss and color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

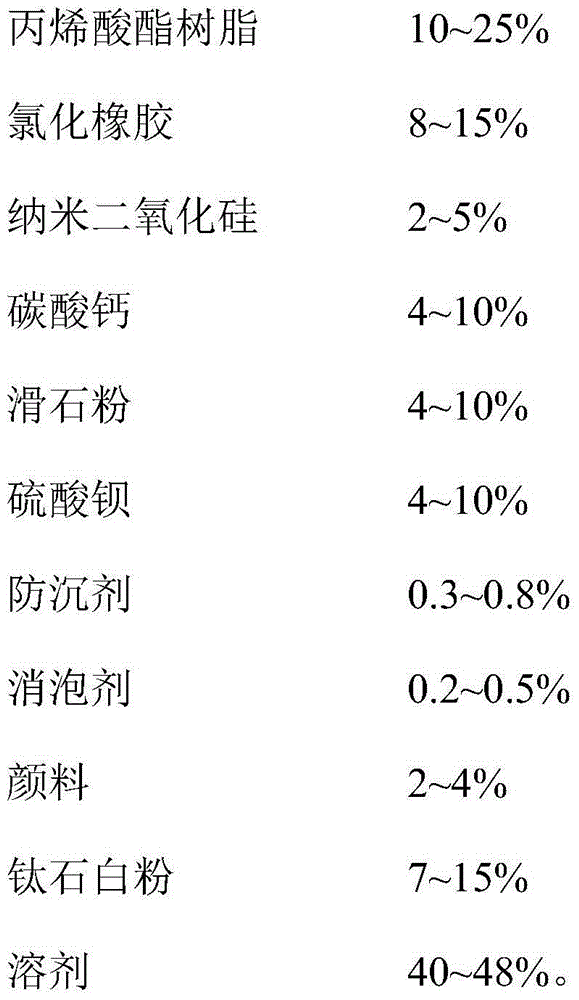

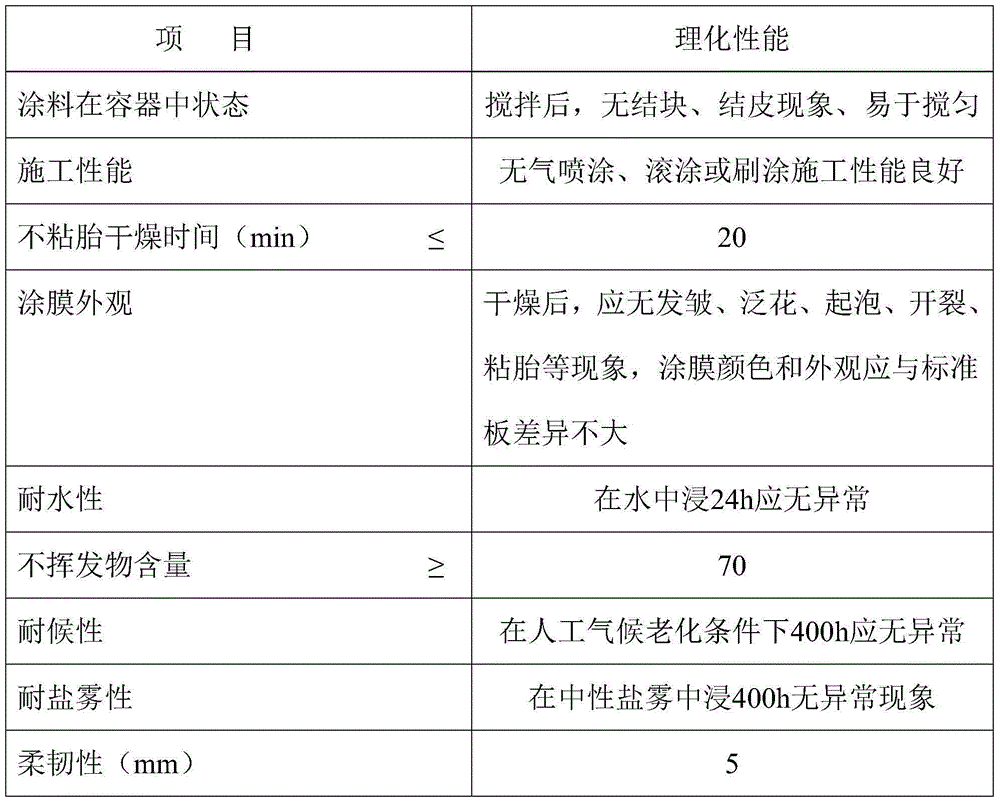

Method used

Image

Examples

Embodiment 1

[0016]

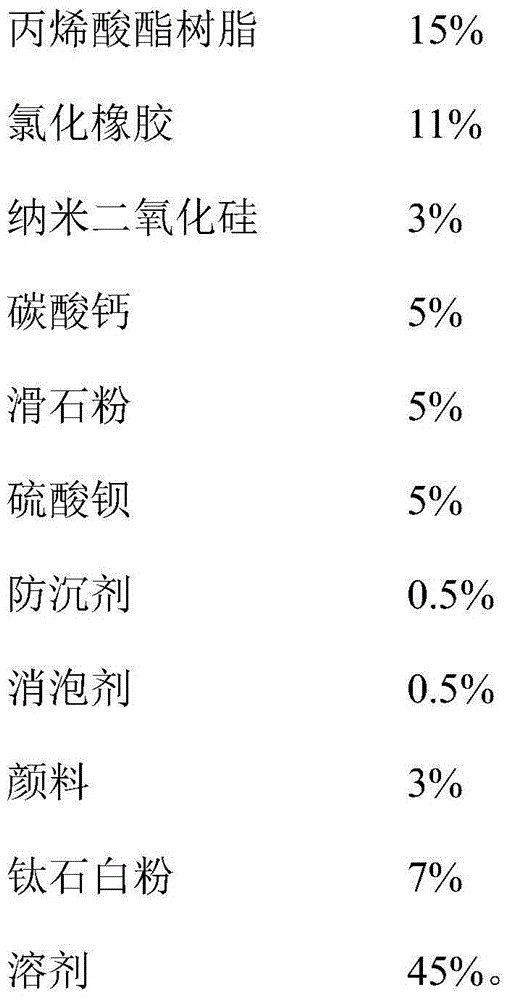

Embodiment 2

[0018]

Embodiment 3

[0020]

[0021] Preparation technique of the present invention comprises the following steps:

[0022] a. Ingredients: mix acrylic resin, chlorinated rubber, calcium carbonate, talcum powder, barium sulfate, anti-sedimentation agent, defoamer, pigment, and titanium white powder according to the proportion;

[0023] b. Grinding: adding nano-silicon dioxide with a fineness of 18 to 22 nm in the mixture of step a for grinding, the grinding time is 60 min, and the grinding speed is 600 rpm;

[0024] c. Reaction: Put the mixed materials in step b into the reactor, add solvent in the reactor according to the proportion to react, the reaction temperature is 100°C, and the reaction time is 20-22h;

[0025] d. Paint adjustment: measure the viscosity value of the paint obtained in step c by applying the 4-cup measurement method, add acrylate resin and solvent, and control the paint viscosity at 100-150s;

[0026] e. Filtration: filter the paint with a 300-mesh filter to filter out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com