Single-component flame-retardant ketoxime-removed/dealcoholized room temperature vulcanized organosilicon sealant and preparation method thereof

A room temperature vulcanization and deketoxime technology, which is applied in chemical instruments and methods, adhesives, and other chemical processes, can solve the problems of increasing process complexity and production costs, slow vulcanization speed, and poor storage stability, and achieve excellent storage stability properties, good flame retardancy, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

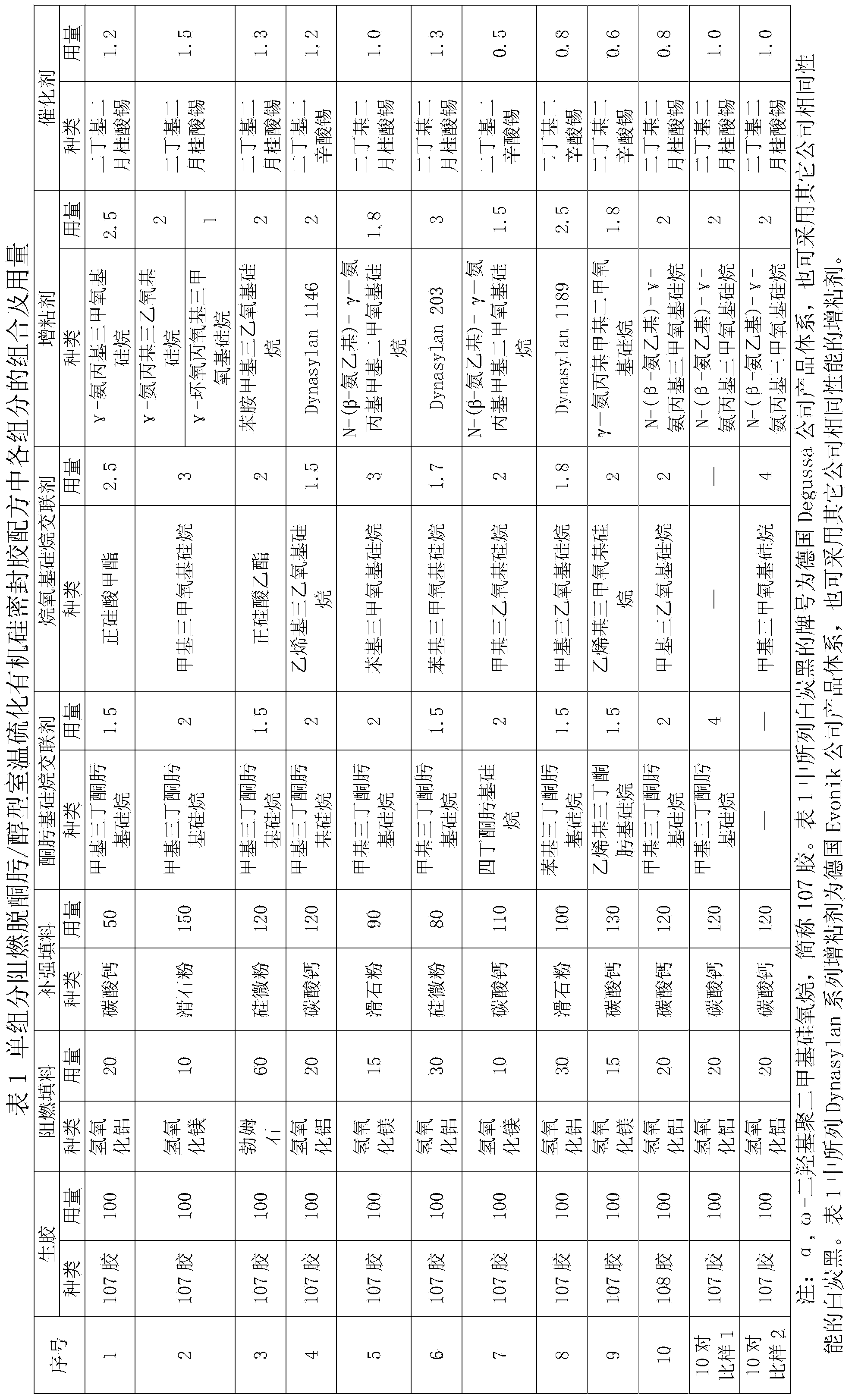

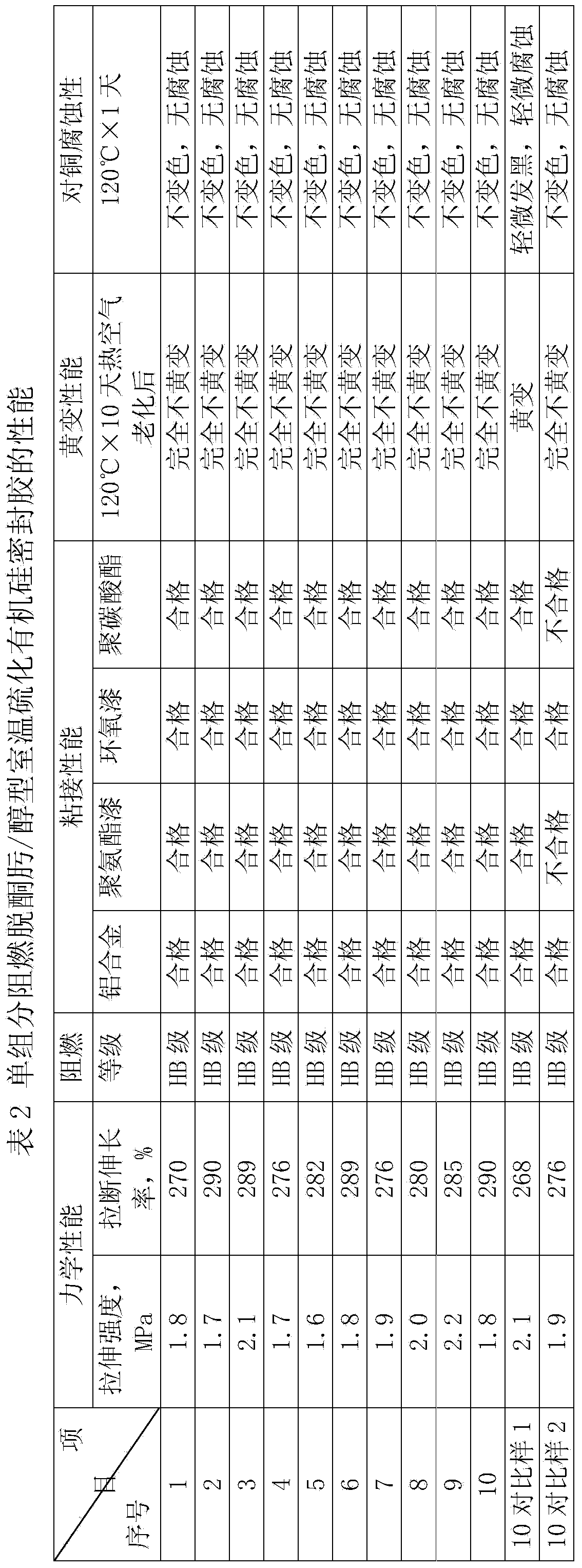

[0020] Below in conjunction with embodiment technical solution of the present invention will be described in further detail:

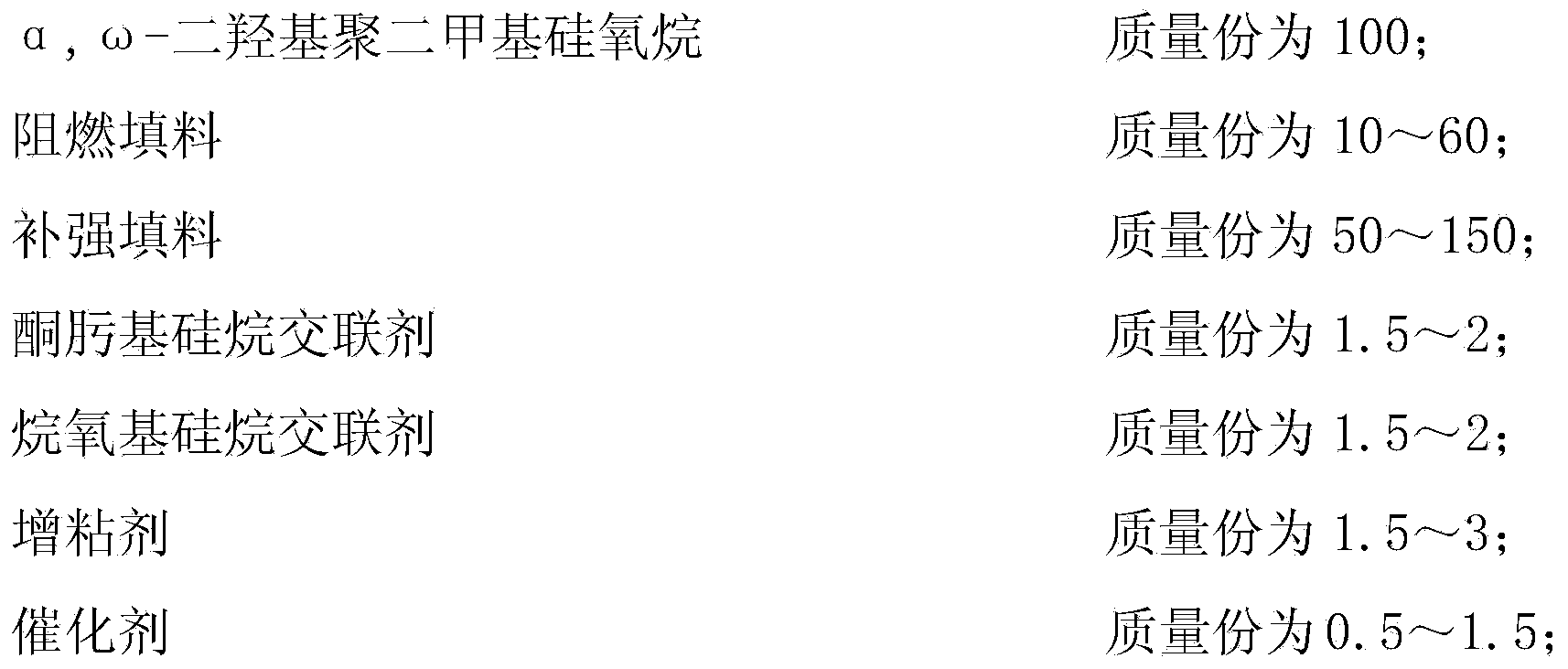

[0021] The composition and mass parts dosage of the sealant described in the technical solution of the present invention are shown in Table 1.

[0022] Taking each component of No. 1 in Table 1 as an example, the method for preparing a single-component flame-retardant deketoxime / alcohol room temperature vulcanizing silicone sealant is described in detail below:

[0023] Weigh each component according to the proportion, first put 100 parts of α, ω-dihydroxy polydimethylsiloxane and 1.5 parts of methyl tributylketoxime silane into a vacuum kneader, heat to 70℃~ 90°C, vacuumize to 0.06-0.09MPa and stir at a constant speed for 1h-1.5h, then add 20 parts of aluminum hydroxide and 50 parts of calcium carbonate and vacuumize to 0.06-0.09MPa at 60°C-80°C and stir at a constant speed for 1h ~1.5h, then put in 2.5 parts of methyl orthosilicate and 1.2 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com