Film-forming agent for air-conditioning cooling fin and preparation method of film-forming agent

A film-forming agent and cooling fin technology, applied in the field of daily chemicals, can solve the problems of increasing energy consumption, shortening the service life of air conditioners, reducing the heating and cooling efficiency of air conditioners, etc., to reduce odor, inhibit growth, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

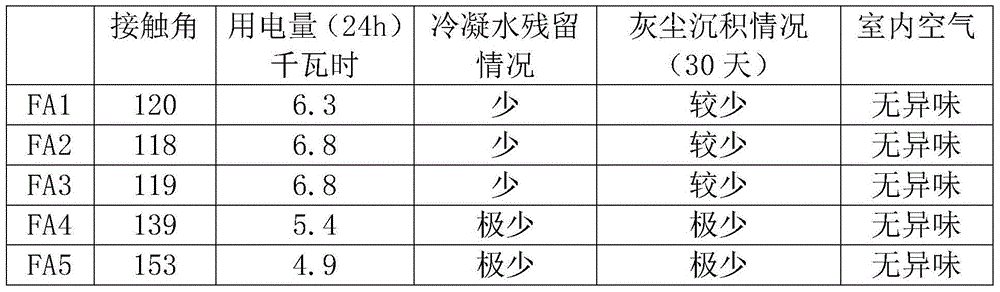

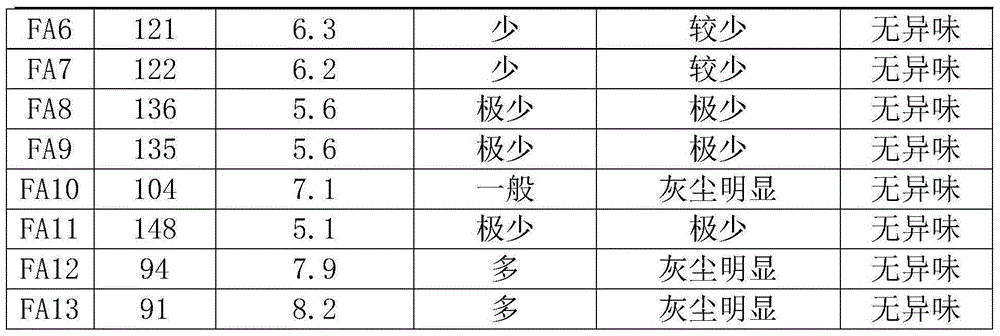

Examples

Embodiment 1

[0019] A film-forming agent for an air-conditioning heat sink provided in this embodiment is composed of the following materials: 47 g of 95% ethanol, 1 g of diethylhexyl carbonate, and 1 g of diquaternized polydimethylsiloxane.

[0020] The above-mentioned preparation method of the film-forming agent for air-conditioning fins:

[0021] At room temperature (15-30°C), add 47g of water to the beaker, then continue to add 1g of diethylhexyl carbonate and 1g of diquaternary polydimethylsiloxane to the beaker, and stir evenly (stir for more than 30s) , to obtain a film-forming agent, denoted as FA1.

[0022] Fill the film former into a storage bottle and set aside.

[0023] When using, spray the film-forming agent on the cleaned air conditioner radiator to completely wet the air conditioner radiator.

Embodiment 2

[0025] A film-forming agent for an air-conditioning heat sink provided in this embodiment is composed of the following substances: 47g of 95% ethanol, 1g of diethylhexyl carbonate, 1g of diquaternized polydimethylsiloxane, 0.1g of para-chlorine Meta-xylenol, 0.9g dodecyl polyoxyethylene ether (AEO9), 0.5g essence.

[0026] The above-mentioned preparation method of the film-forming agent for air-conditioning fins:

[0027] At room temperature (15-30° C.), add 47 g of 95% ethanol to the beaker, then add 1 g of diethylhexyl carbonate and 1 g of diquaternized polydimethylsiloxane, and stir evenly (stir for more than 30 s). Then, 0.1 g of p-chlorometa-xylenol, 0.9 g of AEO9 and 0.5 g of essence were added to the beaker, and the mixture was stirred evenly (stir for more than 30 s) to obtain a film-forming agent, denoted as FA2.

[0028] Fill the film former into a storage bottle and set aside.

[0029] When in use, spray the film-forming agent on the air-conditioning fins to compl...

Embodiment 3

[0031] A film-forming agent for an air-conditioning heat sink provided in this embodiment is composed of the following substances: 47g of 95% ethanol, 1g of diethylhexyl carbonate, 1g of diquaternized polydimethylsiloxane, 0.1g of para-chlorine Meta-xylenol, 0.9g AEO9, 50ml nitrogen.

[0032] The above-mentioned preparation method of the film-forming agent for air-conditioning fins:

[0033] At room temperature (15-30° C.), add 47 g of 95% ethanol to the beaker, then add 1 g of diethylhexyl carbonate and 1 g of diquaternized polydimethylsiloxane, and stir evenly (stir for more than 30 s). Then, 0.1 g of p-chloro-meta-xylenol and 0.9 g of AEO9 were added to the beaker, and the mixture was stirred evenly (stir for more than 30 s) to obtain a stock solution.

[0034] The stock solution was poured into a 100ml tinplate aerosol can, and 50ml of nitrogen was charged into the tinplate aerosol can, and the nozzle was covered to prepare a film-forming agent stored in the tinplate aero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com