Supercritical carbon dioxide solid thickening agent as well as preparation method and application thereof

A carbon dioxide and thickener technology, applied in chemical instruments and methods, bulk chemical production, drilling compositions, etc., can solve the problems of unfavorable storage, transportation and environmental protection, high cost, high consumption, etc., and achieve improvement Oil recovery, good thickening, good storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

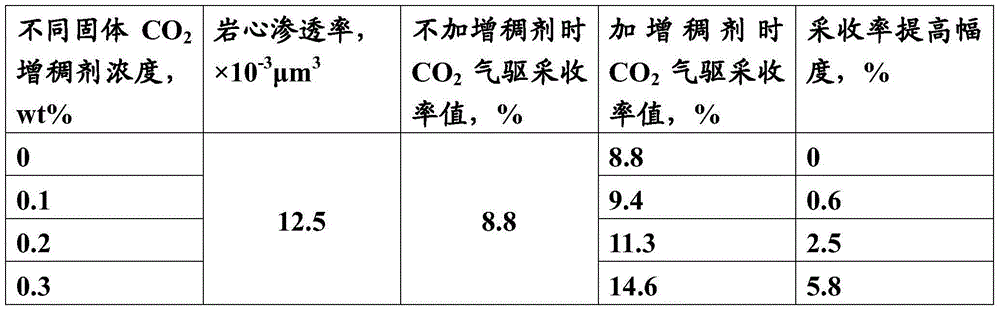

Examples

preparation example Construction

[0037] The present invention also provides the preparation method of described supercritical carbon dioxide solid thickener, comprises the following steps:

[0038] (1) Mix components (a), (b), (e) and (f) uniformly, and react at 70°C-100°C for 3-8h;

[0039] (2) Add (c) and (d) and mix well, stop stirring, and continue to react at 70°C-100°C for 3-8h;

[0040] (3) remove the solvent in the above-mentioned reaction product;

[0041] (4) Lower the temperature to below 30°C, and shear granulate to obtain the product; the particle size is 10-35um, preferably 12-25um.

[0042] In a specific embodiment of the present invention, step (3) is carried out under the condition of a vacuum degree of 0.01-0.1 MPa.

[0043] The present invention also provides the use of the supercritical carbon dioxide solid thickener in oil field development to enhance oil recovery.

[0044] The thickener of the present invention can be injected into the stratum to be treated by directly adding the thic...

Embodiment 1

[0065] Raw material composition and ratio

[0066] (a) diphenylmethane diisocyanate (250.2g, 1mol), (b) polydimethylsiloxane (85.0g, 0.7mol) with a viscosity of 50mPa.s, (c) trifluoroethanol (10.1g, 0.1 mol) and (d) trimethylolpropane (19.9g, 0.15mol) ratio of substance is 1.0: 0.7: 0.1: 0.15; (e) acetone and (f) dibutyltin dilaurate account for (a) , (b), (c) and (d) 15% and 0.01% of the total mass.

[0067] Preparation:

[0068] Turn on the mixer, mix (a), (b), (e), (f) evenly, and react at 80°C for 4 hours; then add (c), (d) and mix well, stop stirring, and continue the reaction at 80°C 8h; under the condition of vacuum degree of 0.02MPa, remove acetone; then lower the temperature to 25°C and shear granulate to obtain the product.

Embodiment 2

[0070] Raw material composition and ratio

[0071] Weigh 222.3g component (a) isophorone diisocyanate (1.0mol), according to the mass ratio of component (a): (b): (c): (d) is 1.0: 0.9: 0.02: 0.05 Weighing component (b) viscosity is the polydimethylsiloxane of 5000mPa.s, component (c) octafluoropentanol and component (d) glycerin respectively, and make component (e) acetone and component (f) Dibutyltin dilaurate accounts for 80% and 0.1% of the total mass of (a), (b), (c) and (d) respectively.

[0072] Preparation method: Turn on the mixer, mix (a), (b), (e), (f) evenly, and react at 70°C for 6 hours; then add (c), (d) and mix evenly, stop stirring, and Continue to react at ℃ for 5 hours; remove acetone under the condition of vacuum degree of 0.02MPa; then lower the temperature to 25℃ and shear granulate to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com