Real-time and in-situ quantitative determination method of mass of solution in thin polymer film and viscoelasticity of thin polymer film

A polymer film and solution technology, applied in the field of measurement, can solve problems such as unsatisfactory fitting conditions and cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

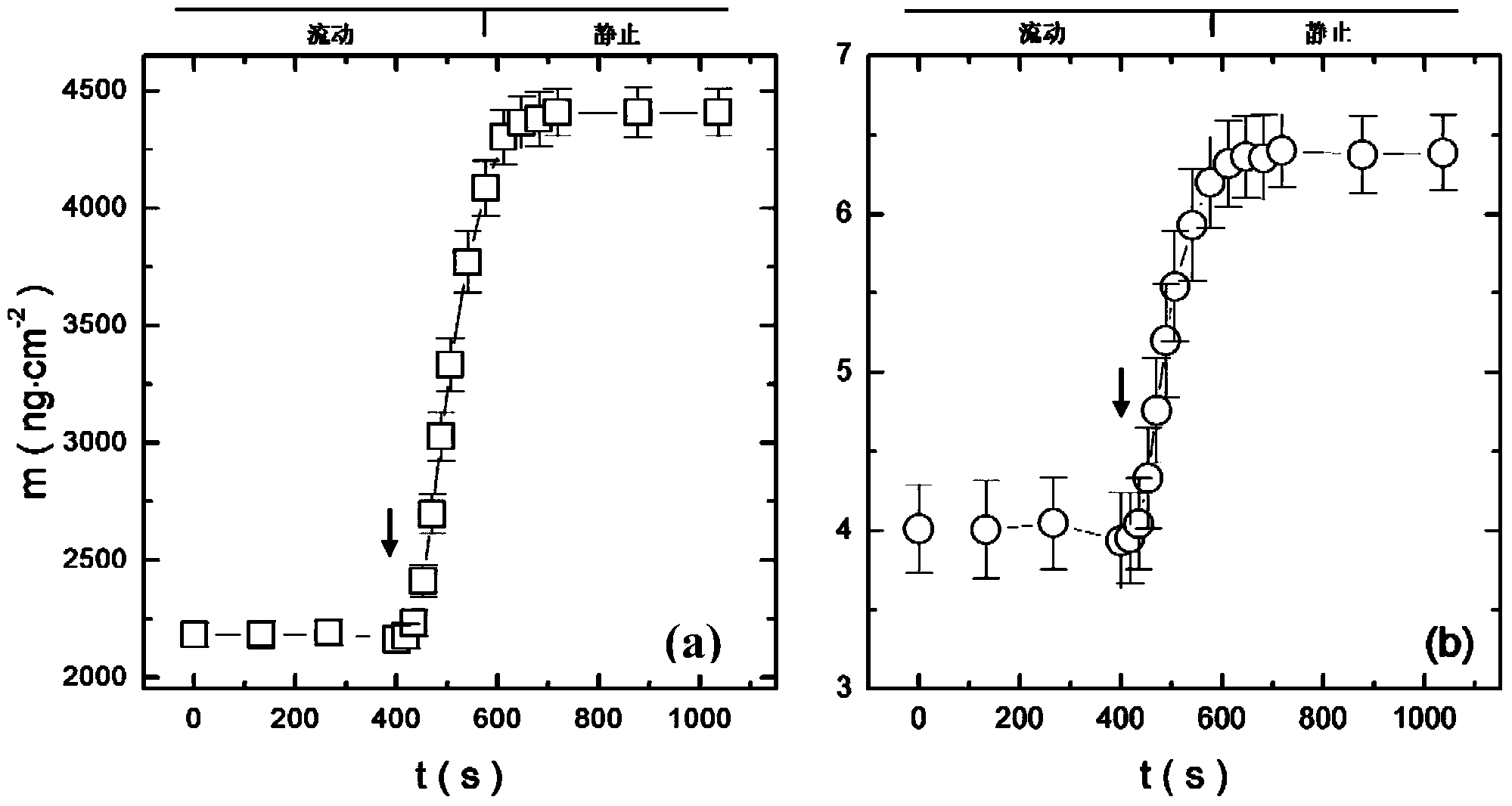

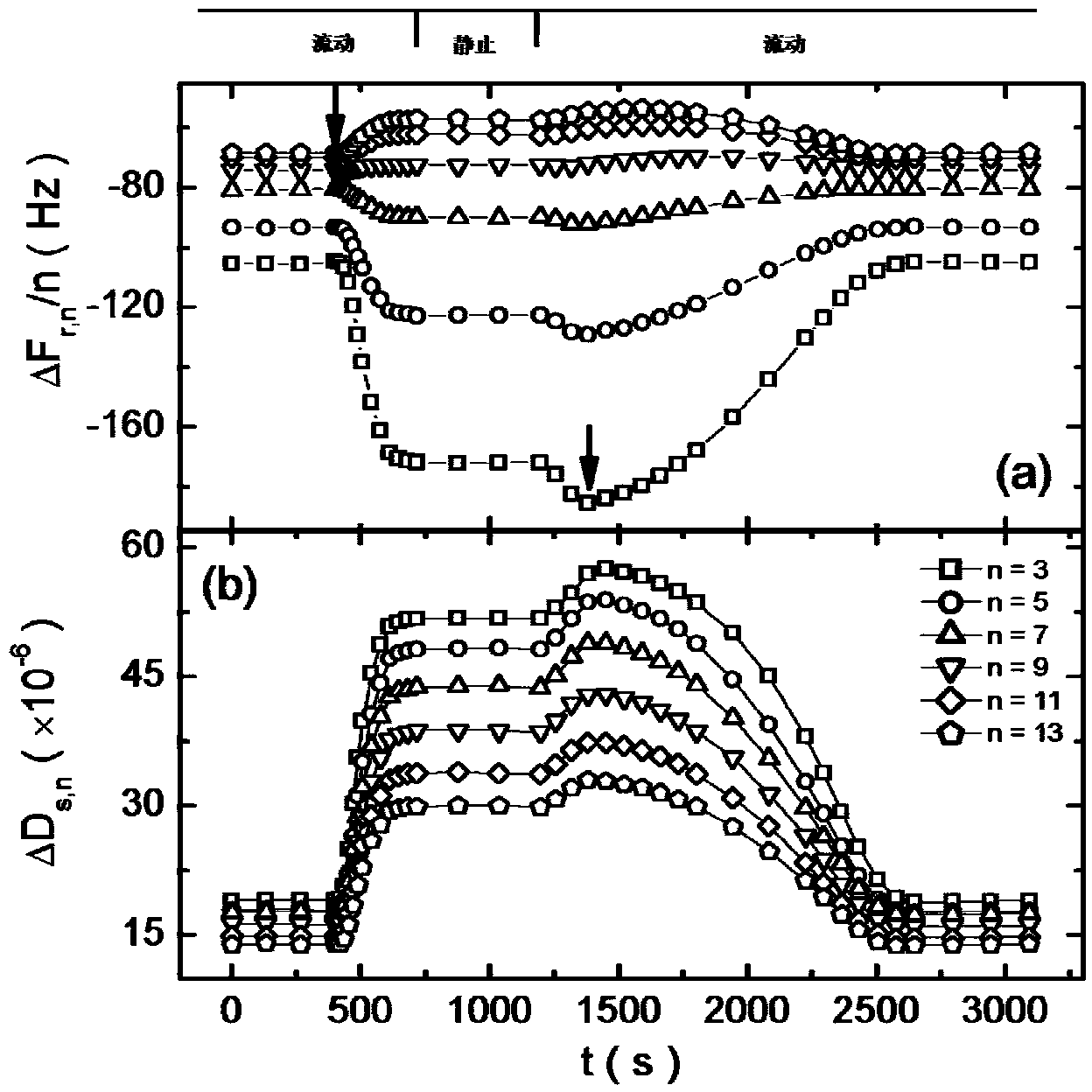

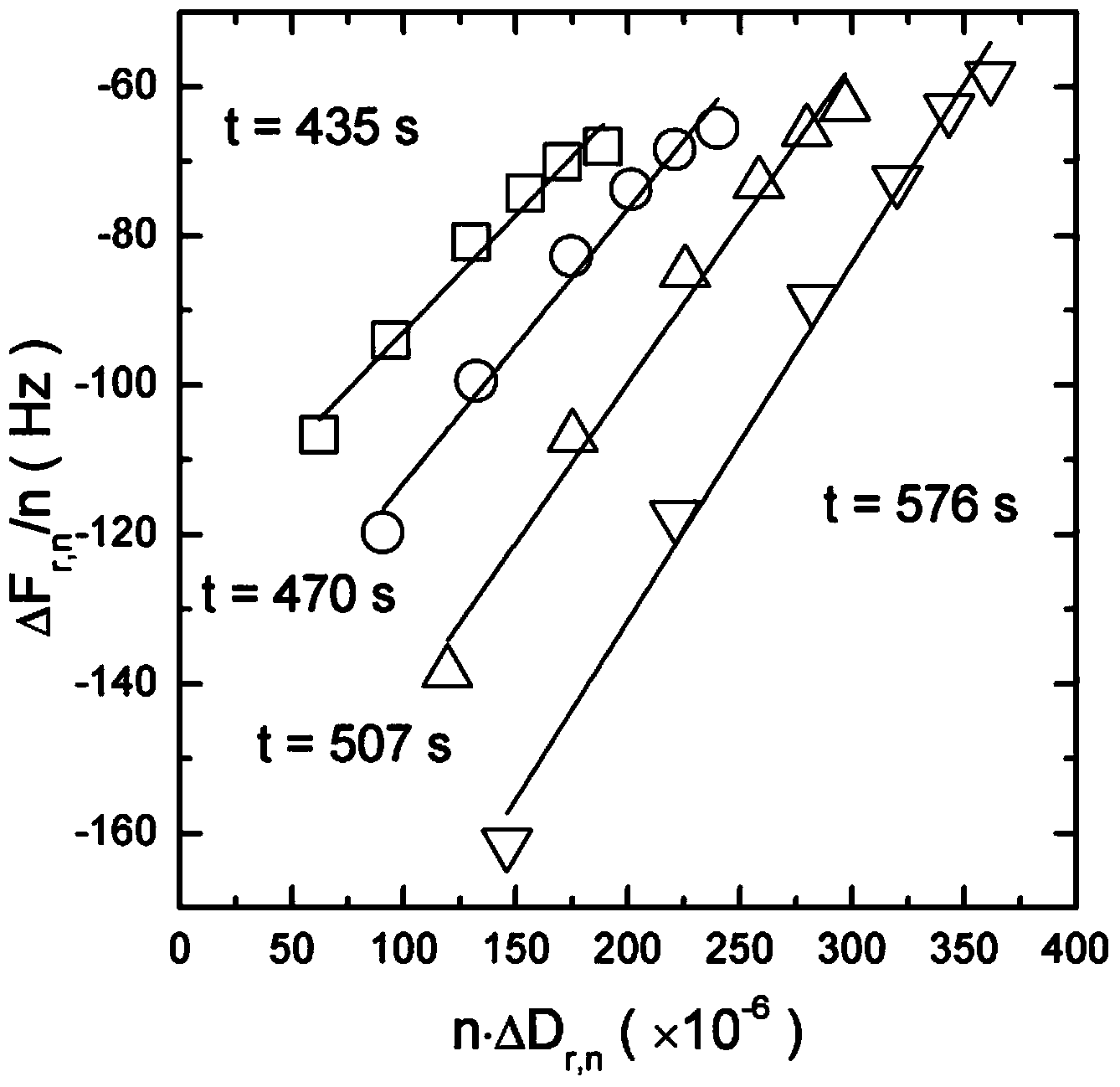

[0025] Real-time measurement of solution quality and its viscoelasticity in embodiment 1, sodium polystyrene sulfonate brush

[0026] 1) Preparation of sodium polystyrene sulfonate brush: the chip with silicon dioxide coating on the surface is subjected to hydrophilic treatment to make the surface rich in silicon hydroxyl groups. The dry silicon chip was placed in an anhydrous cyclohexane solvent of epoxy silane reagent (5,6-epoxyhexyltriethoxysilane) for self-assembly to make the surface rich in epoxy groups. Amino-terminated polystyrene (PS-NH 2 , M n =32×10 3 g·mol -1 ; w / M n =1.04) toluene solution was spin-coated on the chip surface rich in epoxy groups, and reacted in a vacuum oven at 160°C for 24h. Afterwards, ungrafted polystyrene molecules are rinsed off with toluene, that is, unreacted polystyrene molecules on the surface are washed off to obtain a polystyrene brush. Then use the 1,2-dichloroethane solution of sulfuric acid and acetic anhydride (volume ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com