Multi-junction solar cell based on semiconductor quantum dot, and manufacturing method thereof

A technology of solar cells and production methods, applied in the field of solar cells, can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for manufacturing a multi-junction solar cell based on semiconductor quantum dots,

[0034] Include the following steps:

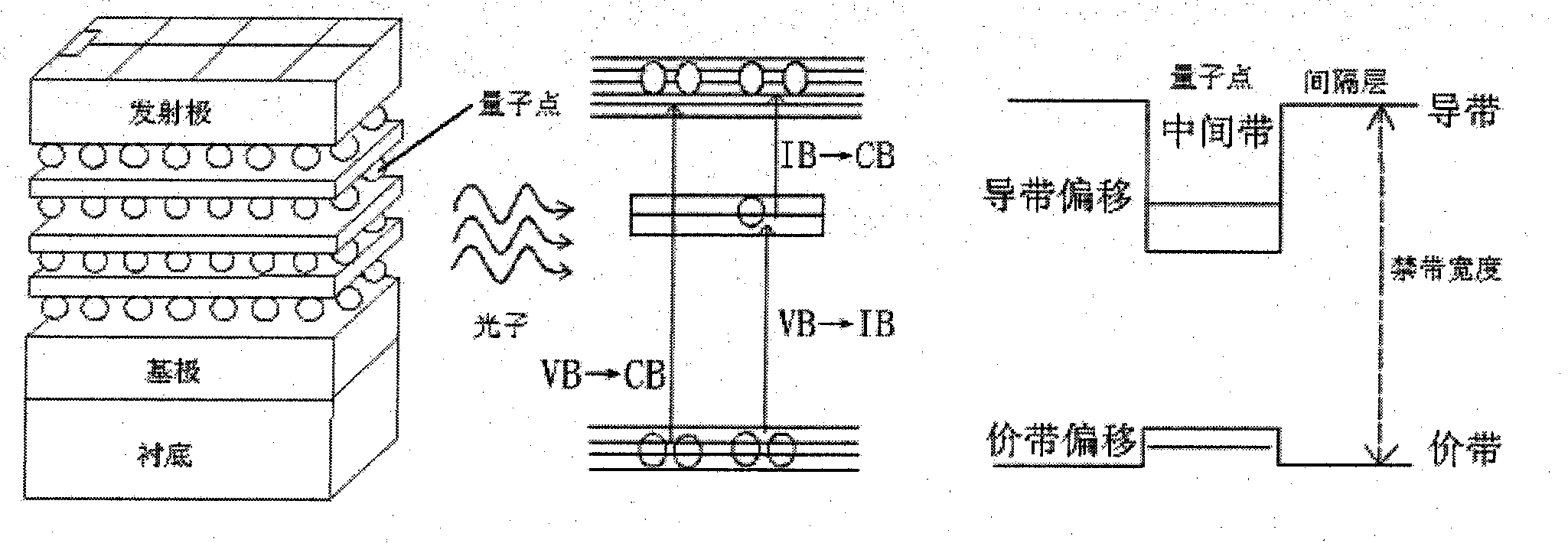

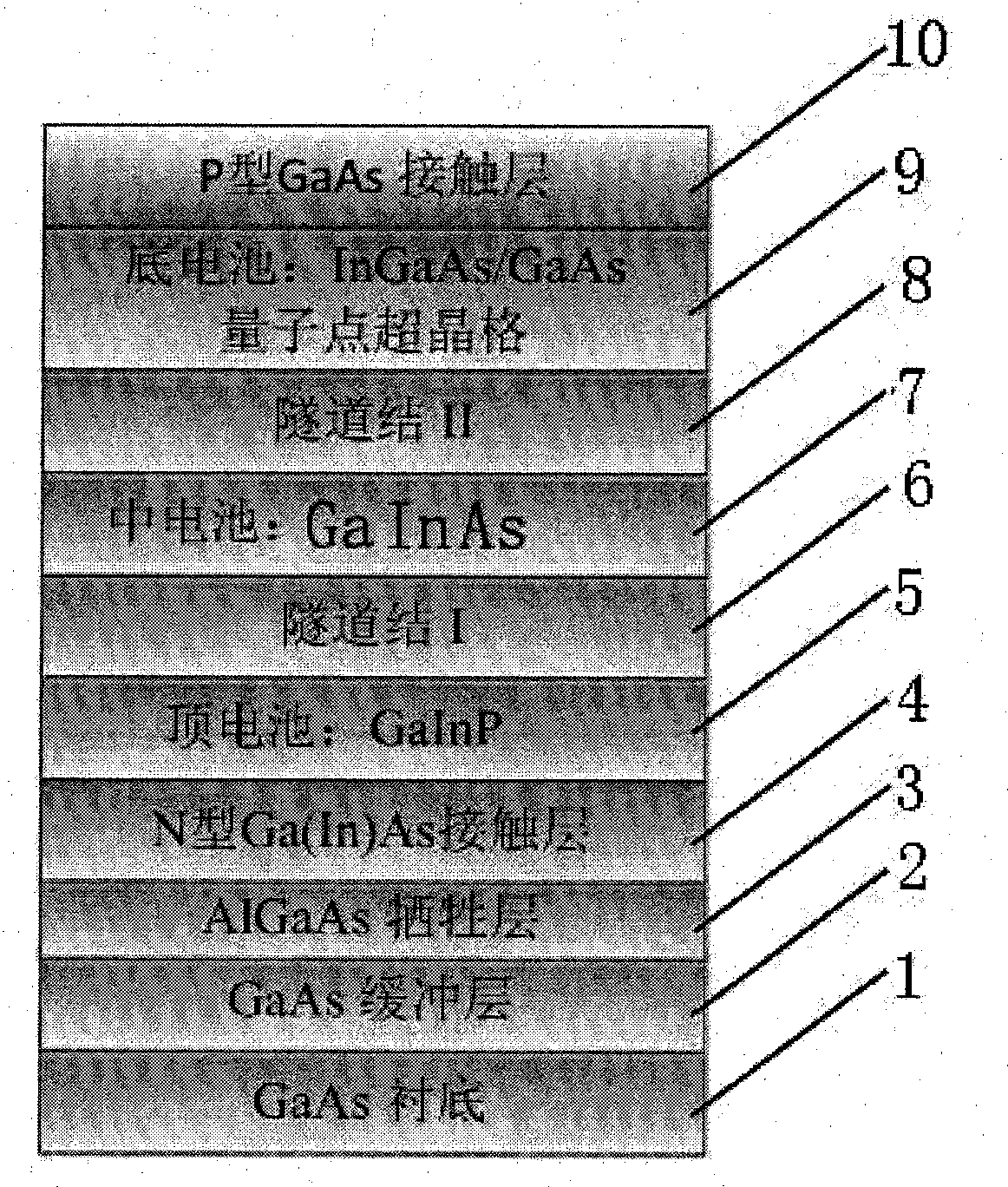

[0035] Step S1: epitaxially grow the buffer layer 2, the sacrificial layer 3 and the solar cell layer on the GaAs substrate 1 in order to produce a solar cell epitaxial wafer. The solar cell layer includes an N-type contact layer 4, a GaInP top cell 5, a tunnel junction I6, and GaInAs Middle cell 7, tunnel junction II8, InGaAs / GaAs quantum dot bottom cell 9 and P-type contact layer 10, the band gap of GaInP top cell 5 is 1.80-1.92eV, and the band gap of GaInAs middle cell 7 is 1.38-1.42eV , the forbidden band width of the InGaAs / GaAs quantum dot bottom cell 9 is 1.0-1.3eV. Specifically, the InGaAs / GaAs quantum dot bottom cell 9 includes a quantum dot superlattice structure and a base and an emitter that are separately arranged on both sides of the quantum dot superlattice structure, and the quantum dot superlattice...

Embodiment 2

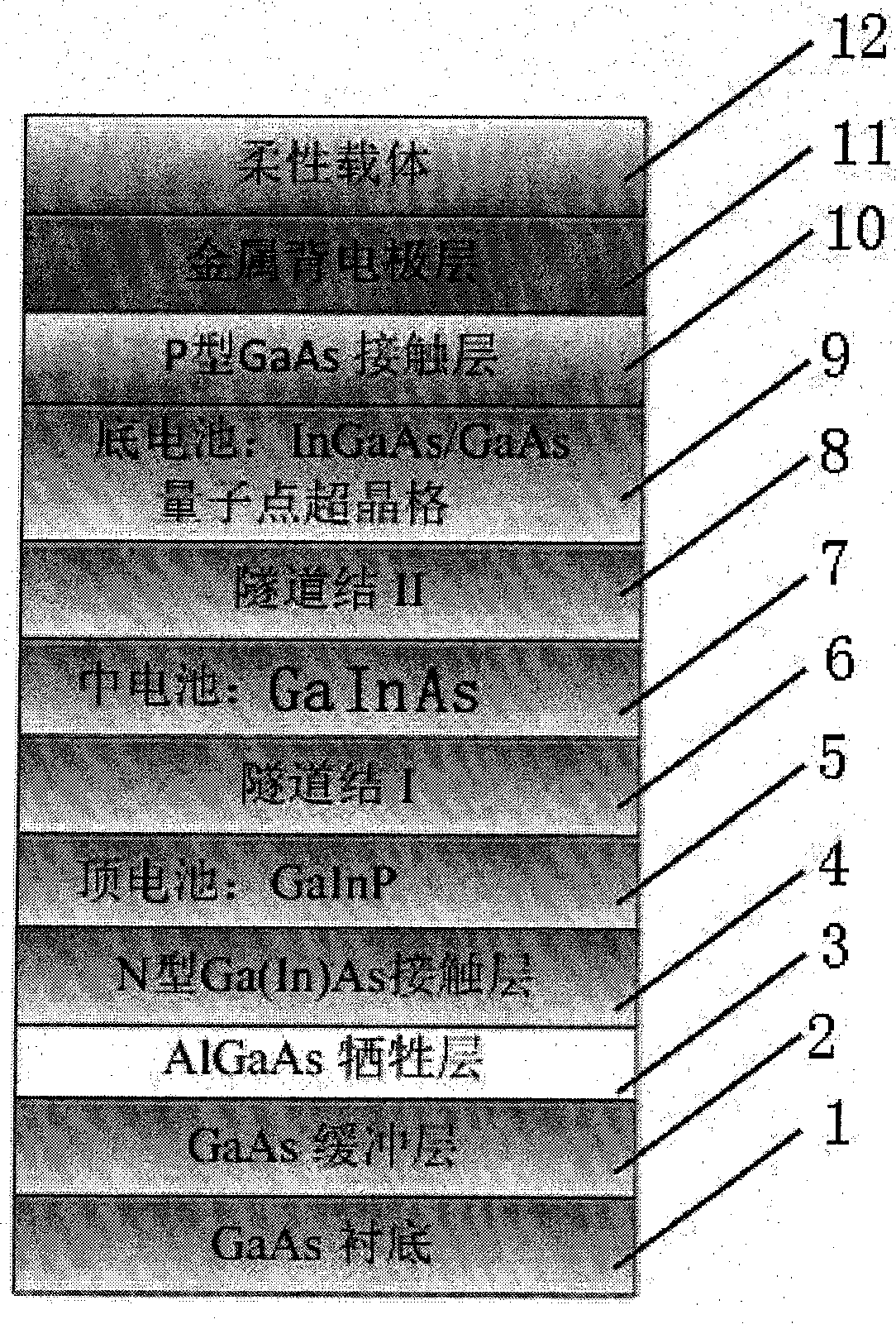

[0049] Such as Figure 5 As shown, this embodiment provides a multi-junction solar cell based on semiconductor quantum dots, including a control chip and a plurality of series and / or parallel battery cells connected to the control chip, characterized in that the battery cells are from top to The bottom includes metal back electrode layer 11, P-type contact layer 10, InGaAs / GaAs quantum dot bottom cell 9, tunnel junction II8, GaInAs middle cell 7, tunnel junction I6, GaInP top cell 5, and N-type contact layer 4. It also includes an anti-reflection film 14 and an upper electrode 13 arranged on the N-type GaInAs contact layer.

[0050] Specifically, the InGaAs / GaAs quantum dot bottom cell 9 includes a quantum dot superlattice structure and a base and an emitter that are separately arranged on both sides of the quantum dot superlattice structure, and the quantum dot superlattice structure includes at least one layer of In x Ga 1-x As quantum dot layer, and set in In x Ga 1-x G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Lattice constant | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com