Circuit and method for synchronous rectification of Jensen circuit

A technology of synchronous rectification and full-wave rectification circuit, which is applied in the direction of high-efficiency power electronic conversion, electrical components, and adjustment of electrical variables, and can solve the problems of inability to realize soft switching technology, complex circuits, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

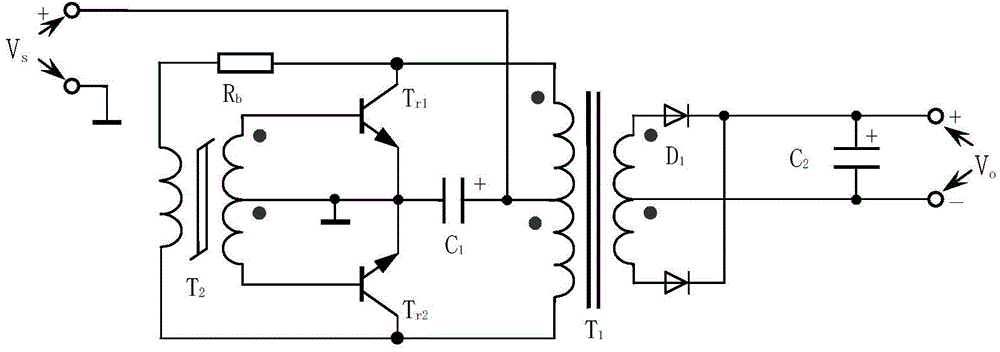

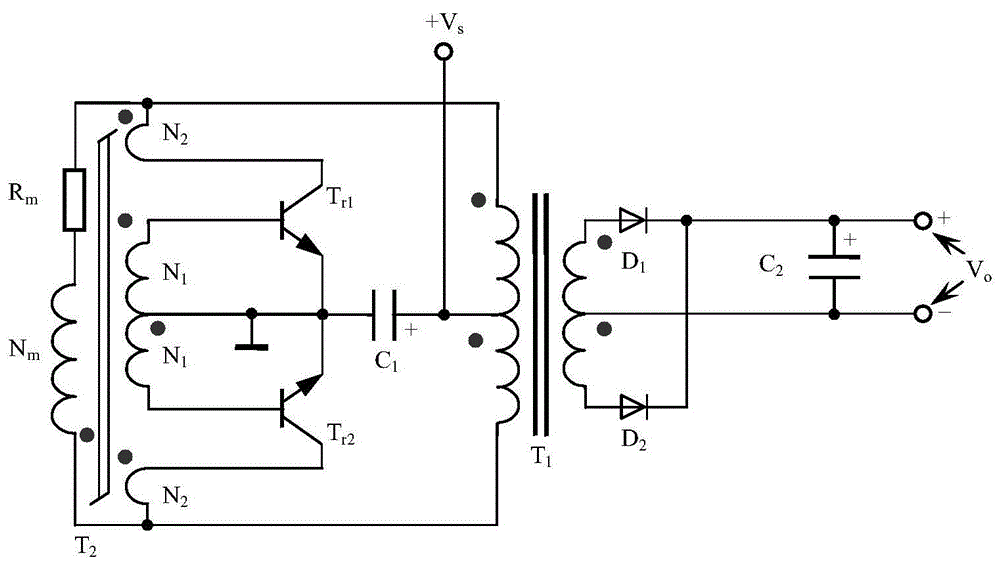

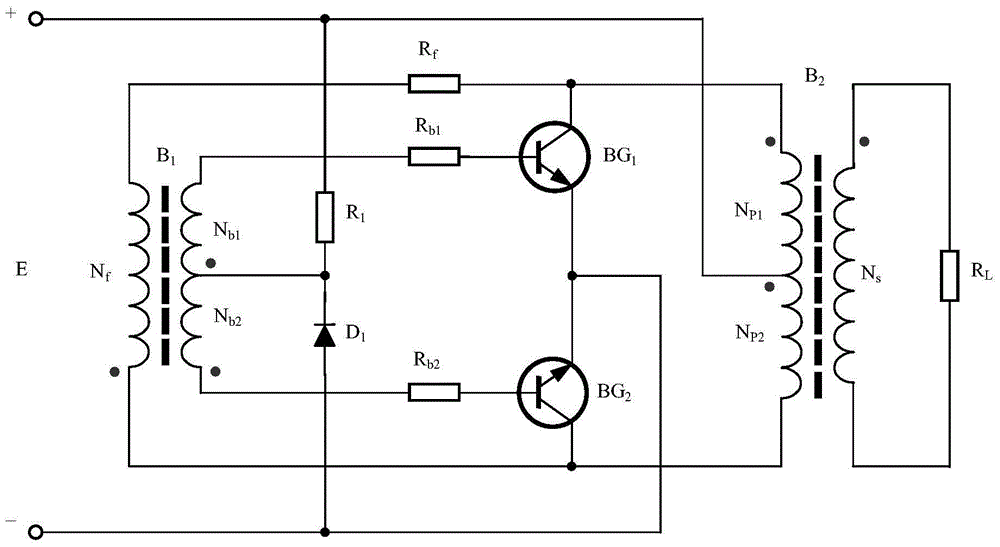

[0098] see Figure 5 . First show the circuit parameters and measured performance of the existing technology, Figure 5 The Jingsen circuit is designed as a converter with an input of 48V and an output of 12V / 1A: the resistor R1 is 33K, the resistor Rb is 16K, the capacitor C1 is 0.047uF / 16V, the parameters of the switch tube: both the triode TR1 and TR2 are FZT853, the withstand voltage Only 100V, the measured value is more than 130V, used in the circuit, the test is not a big problem. Capacitor C is a 10uF / 63V electrolytic capacitor, the output uses Figure 6 The full-wave rectification circuit, the diodes D1 and D2 both use 2A / 40V Schottky diodes, and the output filter capacitor C2 uses 10uF / 25V tantalum capacitors; among them, the magnetic saturation transformer B1 uses Tiantong’s TS7 ring core , the initial magnetic permeability is 7500, the outer diameter is 5.05mm, the inner diameter is 2.3mm, the thickness is 1.6mm, the primary side winding is 49 turns, the secondar...

no. 2 example

[0137] see Figure 14 ,and Figure 8 The difference is that the capacitors C1 and R1 are connected in parallel. Paragraphs 0029 to 0035 of the Chinese patent 201210174076.7 discuss that this method only affects the startup and does not affect the normal operation. Figure 14 The Jingsen circuit is designed as a converter that inputs 24V and outputs 5V / 0.2A:

[0138] The resistor R1 is 27K, the resistor Rb is 18K, the capacitor C1 is 0.1uF / 10V, the parameters of the switch tube: the triode TR1 and TR2 are both FMMT493, the withstand voltage is only 150V, and the current is 1A. The output filter capacitor C2 adopts a 2.2uF / 10V chip capacitor; the output adopts a synchronous rectification full-wave rectification circuit, and the full-wave rectification circuit includes the first N-type field effect transistor Q1 and the second N-type field effect transistor Q2; Q1 and Q2 All are XP151A13AOMR N-type FETs with a withstand voltage of 20V and a current of 1A, that is, N-channel FET...

no. 3 example

[0150] see Figure 15 ,and Figure 8 The difference is that a resonant capacitor Cd is connected in parallel with both ends of the primary winding of the drive transformer B1, Figure 15 The Jingsen circuit is designed as a converter with an input of 48V and an output of 12V / 1A. The capacitor Cd is an NPO capacitor of 270pF, and the withstand voltage is 1000V; other parameters are the same as those of the first embodiment of the present invention. After the circuit is welded, its performance is energized and tested:

[0151] The peak-peak value of the AC working voltage at both ends of the primary winding of the saturated transformer is: 272.1V;

[0152] Output no-load static power consumption: 0.24W;

[0153] Full load conversion efficiency: 95.1%;

[0154] Working frequency: 274.9KHz.

[0155] After a resonant capacitor Cd is connected in parallel to both ends of the primary winding of the drive transformer B1, in the solution shown in the third embodiment, its operating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com