Forming method for spherical aluminium oxide through oil-water column process

A spherical alumina and water column technology, applied in the direction of alumina/hydroxide, etc., can solve the problems of product purity and sphericity, long aging time of oil ammonia column method, environmental pollution, etc., and achieve simple and feasible operation steps, Easy industrial production and high product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

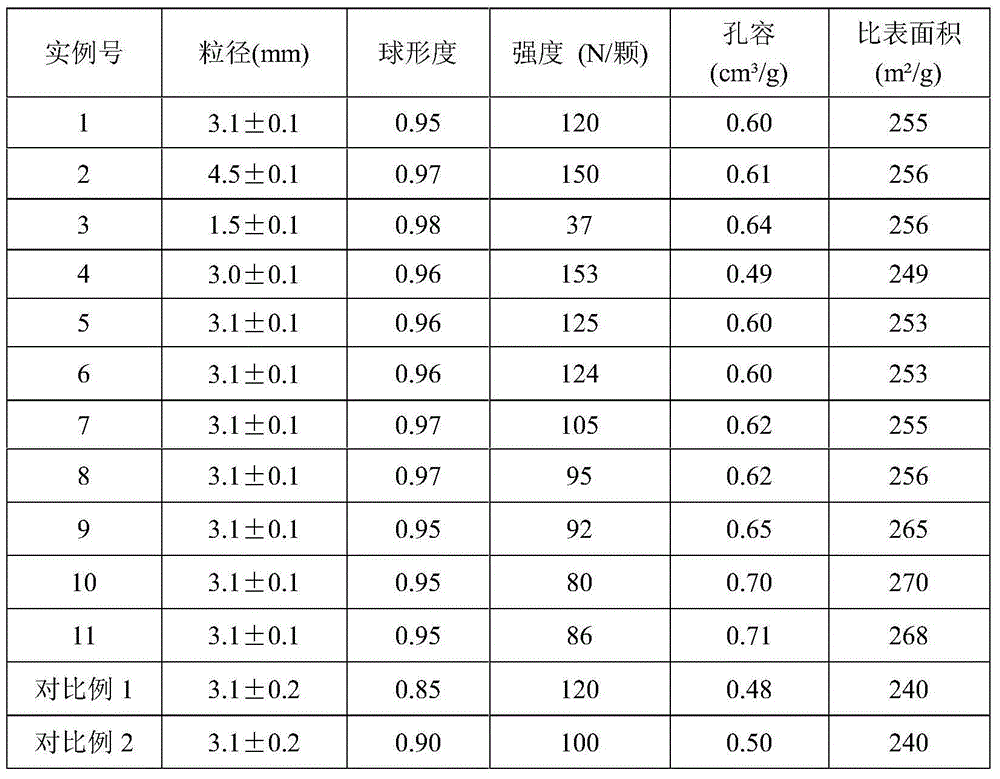

Examples

Embodiment 1

[0025] Prepare spherical alumina by the method step of the present invention:

[0026] 100 g of SB powder (pseudo-boehmite) produced by Sasol, Germany, was added to 300 g of a 3% by weight sodium alginate solution, fully stirred to form an alginate-pseudo-boehmite suspension, and set aside.

[0027] In the oil-water column with a height of 1.2m and a diameter of 30cm, the upper oil phase is lubricating oil with a height of 1mm, and the lower water phase is a 0.5mol / L aluminum nitrate solution with a height of 119cm. A pump is used to control the oil level to be stable.

[0028] Drop the alginic acid-pseudoboehmite suspension from the top of the oil-water column through a ball dropper. The drip nozzle at the bottom of the ball dropper is 2cm away from the oil surface. / Second. Suspension droplets shrink into balls in the oil phase, and smoothly pass through the oil-water interface into the water phase, and the droplets gel into solids in the water phase, and are discharged fr...

Embodiment 2

[0031] Prepare gamma-A by the step in embodiment 1 2 o 3 Small balls, the difference is: 500g of sodium alginate solution with a concentration of 2% by weight is added to the ingredients, and it is fully stirred to form an alginic acid-pseudoboehmite suspension; the height of the upper oil phase in the oil-water column is 15cm, and the lower water phase The height is 104cm; the aperture size of the drip nozzle used when dropping the ball is 3.0mm, and the properties of the obtained ball are shown in Table 1.

Embodiment 3

[0033] Prepare gamma-A by the step in embodiment 1 2 o 3 Small balls, the difference is: 700g of sodium alginate solution with a concentration of 0.5% by weight is added during the batching, fully stirred to form an alginic acid-pseudoboehmite suspension, and a 1mm drip tip is used when dropping the balls, and the prepared small balls The properties of the ball are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com