Method for preparing chloroethylene monomer from dichloromethane

A technology of vinyl chloride monomer and dichloromethane, which is applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc. A wide range of raw material resources, the effect of solving the problem of mercury pollution and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

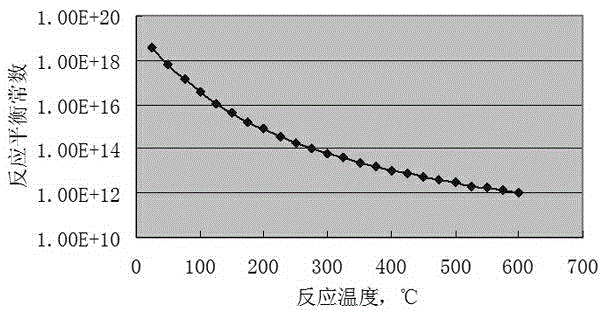

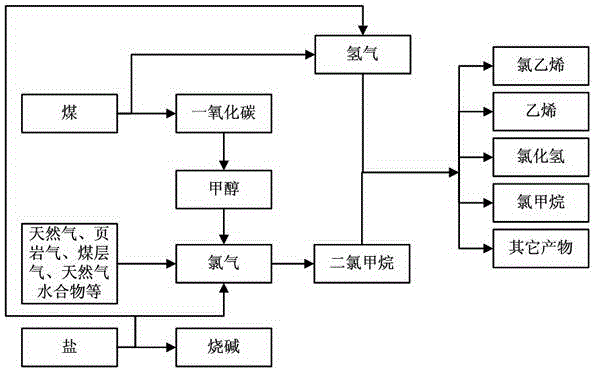

Problems solved by technology

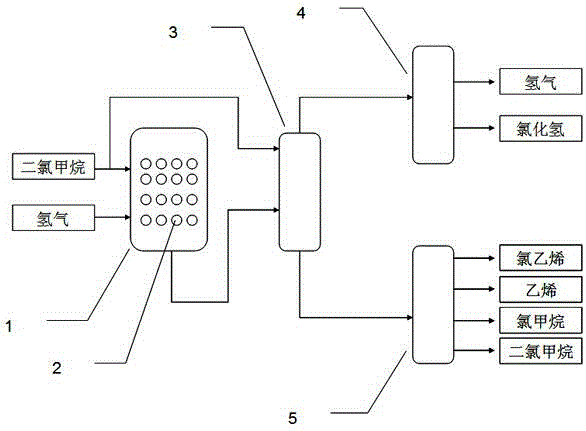

Method used

Image

Examples

Embodiment 1

[0078] Hydrogen and dichloromethane (gasified by heating) were mixed at a molar ratio of 3:1, passed into a reactor without catalyst, and reacted at 450 °C and 1 atm. After the reaction effluent was treated by the subsequent cooling and separation system, it was found that dichloromethane basically did not react.

Embodiment 2

[0080] Mix hydrogen and dichloromethane (gasification by heating) according to the molar ratio of 3:1, pass it into the reactor without catalyst, and use low-temperature plasma technology to activate the reaction raw materials, at 80 ℃, 0.001 atm react. After the reaction effluent is treated by the subsequent cooling and separation system, products such as vinyl chloride, ethylene, and methyl chloride are obtained, and the selectivities are 9%, 13%, and 70%, respectively. The methylene chloride conversion was about 17%.

Embodiment 3

[0082] Precursor compounds of cobalt, molybdenum and iron are prepared into a solution according to a certain ratio, and alumina is used as a carrier, impregnated by an incipient wetness impregnation method, and then dried and roasted to obtain a catalyst. Hydrogen and dichloromethane (gasified by heating) were mixed according to a molar ratio of 3:1, passed into the reactor filled with the above catalyst, and reacted at 450 °C and 1 atm. After the reaction effluent is treated by the subsequent cooling and separation system, products such as vinyl chloride, ethylene, and methyl chloride are obtained, and the selectivities are 28%, 12%, and 35%, respectively. The methylene chloride conversion was about 52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com