Method for increasing separation efficiency of oil field associated gas and recovering carbon dioxide

A technology for oilfield associated gas and carbon dioxide, applied in the chemical industry, can solve the problem of low recovery efficiency of oilfield associated gas, achieve the effects of continuous and stable separation process, reduce processing load and improve light hydrocarbon recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

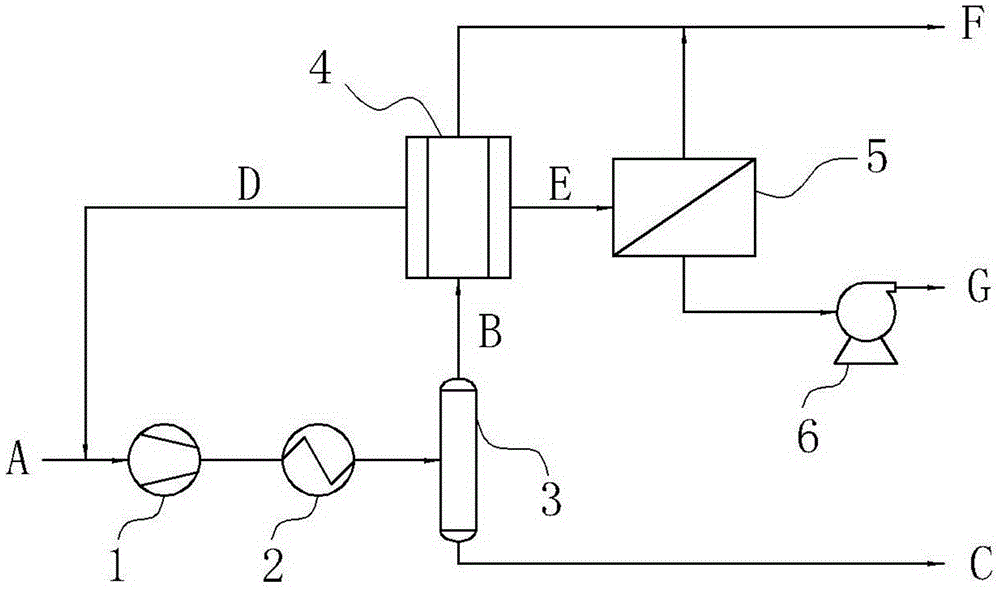

[0022] Please combine the attached figure 1 , In this embodiment, the membrane materials of the double-membrane separator 4 are respectively PEI and PDMS. The pressure of oilfield associated gas A is 150kPa. After being pressurized by compressor 1 to 1500kPa and cooled to -30°C by condenser 2, the gas-liquid phase is separated by liquid separation tank 3 to obtain light hydrocarbons B and non-condensable gas C. The non-condensable gas C enters the double-membrane separator 4 after pretreatment to obtain hydrocarbon-rich gas D, carbon-rich gas E and natural gas F. The hydrocarbon-rich gas D has a pressure of 150kPa and is sent back to the compression condensation system 1 to increase the yield of light hydrocarbons; the carbon-rich gas E has a pressure of 150kPa and enters the single-membrane separator 5 . The single-membrane separator 5 further purifies the enriched carbon dioxide, and the retentate gas is combined with natural gas F. The inlet gas pressure of the vacuum pum...

Embodiment 2

[0026] Please combine the attached figure 1 , operating process and operating conditions are the same as in Example 1. In this embodiment, PI and PTMS are used as the membrane materials of the double-membrane separator 4 respectively. In this embodiment, the recovery rate of light hydrocarbons is 60%, the production of oil displacement gas is 1379kg / h, and the purity of carbon dioxide reaches 99%.

[0027] Table 2 embodiment 2 material balance

[0028]

Embodiment 3

[0030] Please combine the attached figure 1 , the operating process is the same as in Example 1; the outlet pressure of the compressor is raised to 2000kPa, and other operating conditions are the same as in Example 1. In this embodiment, the membrane materials of the double-membrane separator 4 are respectively PEI and PDMS. In this embodiment, the recovery rate of light hydrocarbons is 69%, the production of oil displacement gas is 1392kg / h, and the purity of carbon dioxide reaches 99%.

[0031] Table 3 embodiment 3 material balance

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com