Low-lead free-cutting anti-corrosion tin-brass alloy material

A brass alloy, free-cutting technology, applied in the field of tin-brass alloy materials, can solve the problems of high copper content in silicon brass, poor acceptance, high cost, and achieve the effect of good cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment the present invention is described in further detail, but the present invention is not limited only to embodiment:

[0027] The preparation scheme of the alloy sample of the embodiment of the present invention is:

[0028] Ingredients→melting in power frequency induction furnace→full continuous casting 21.7~21.8mm round bar→stretching φ20.6mm→peeling→φ20.0mm

[0029] The silicon, arsenic, boron, and phosphorus used in the batching process are Cu-Si, Cu-As, Cu-B, and Cu-P. master alloy. Cu-Si alloy, Si content 20%, Cu-As arsenic content 30%, Cu-P phosphorus content 15%, Cu-B boron content 5%.

[0030] The comparison samples were also processed under the same process conditions.

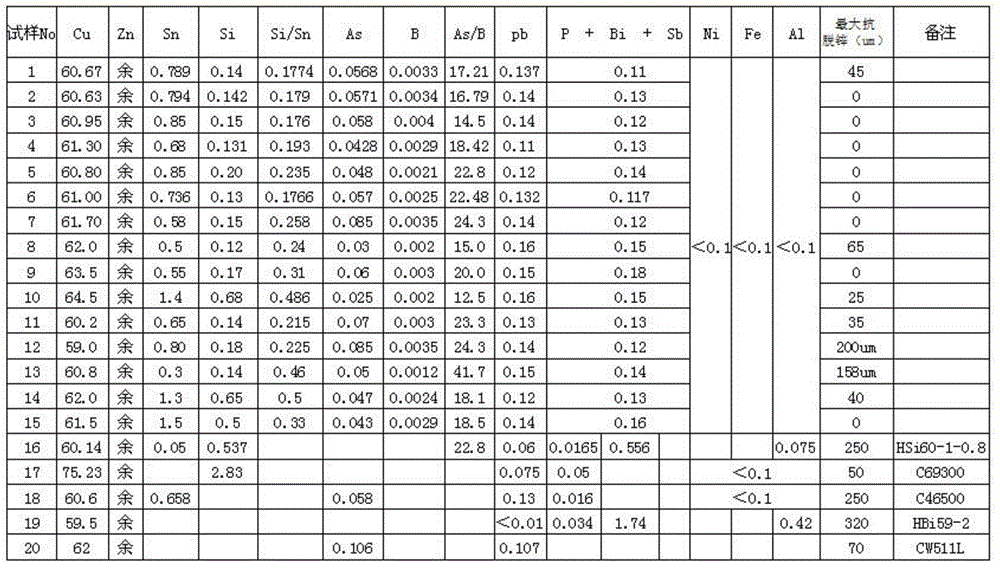

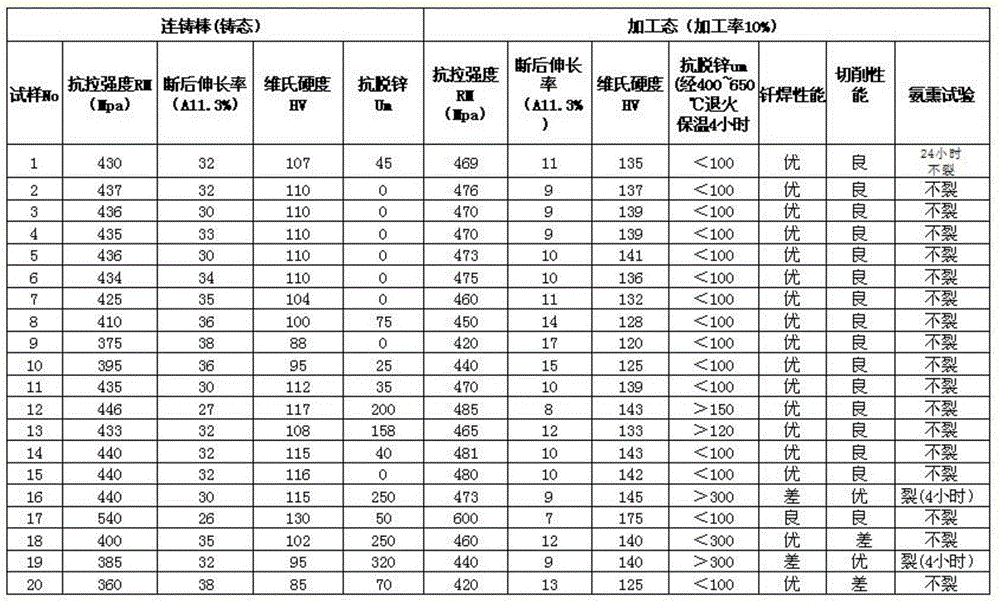

[0031] Each embodiment of low-lead easy-cutting corrosion-resistant brass alloy of the present invention and comparative example specific component content list 1:

[0032] Table 1 embodiment of the present invention and comparative example copper alloy c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com