general high speed engine

An engine and high-speed technology, which is applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems that the speed of the general machine cannot be too high, the structure of the general machine is complicated, and the overall volume is large, so as to achieve simple and compact structure, high speed and sufficient lubrication Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

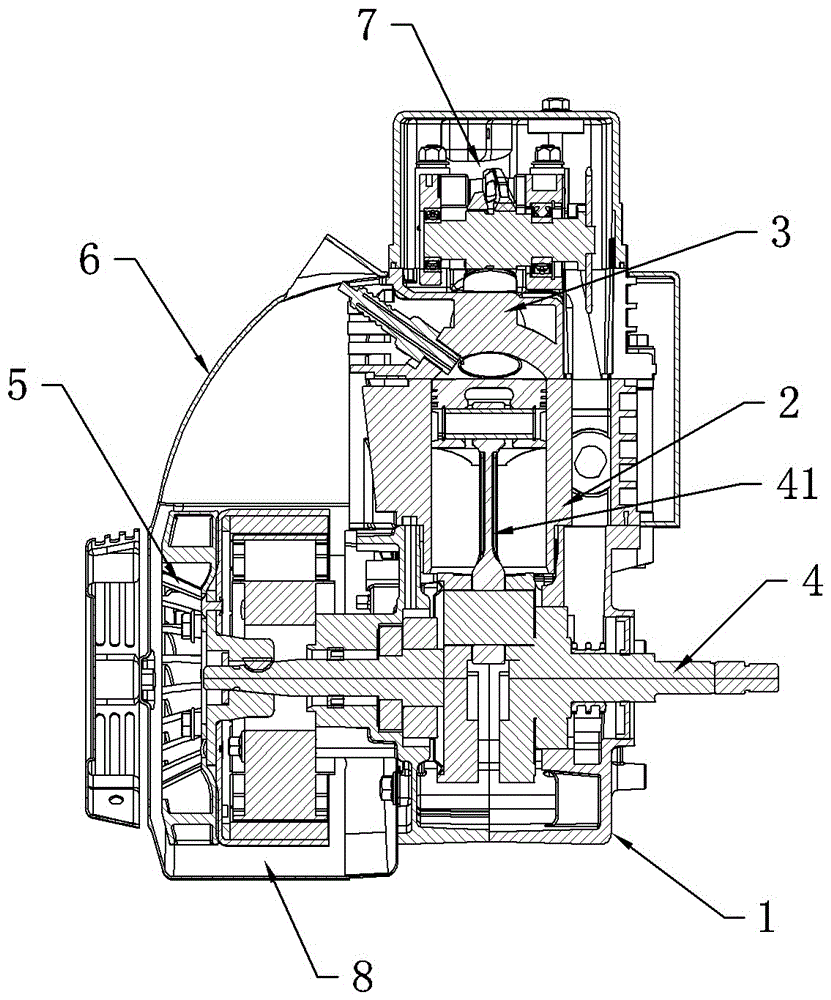

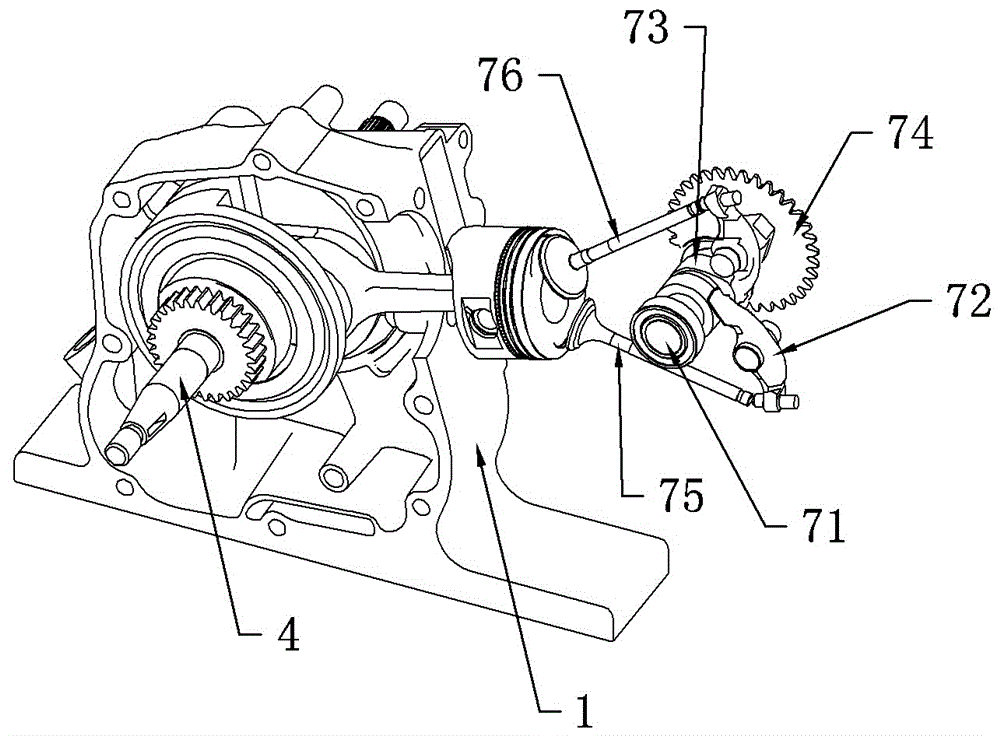

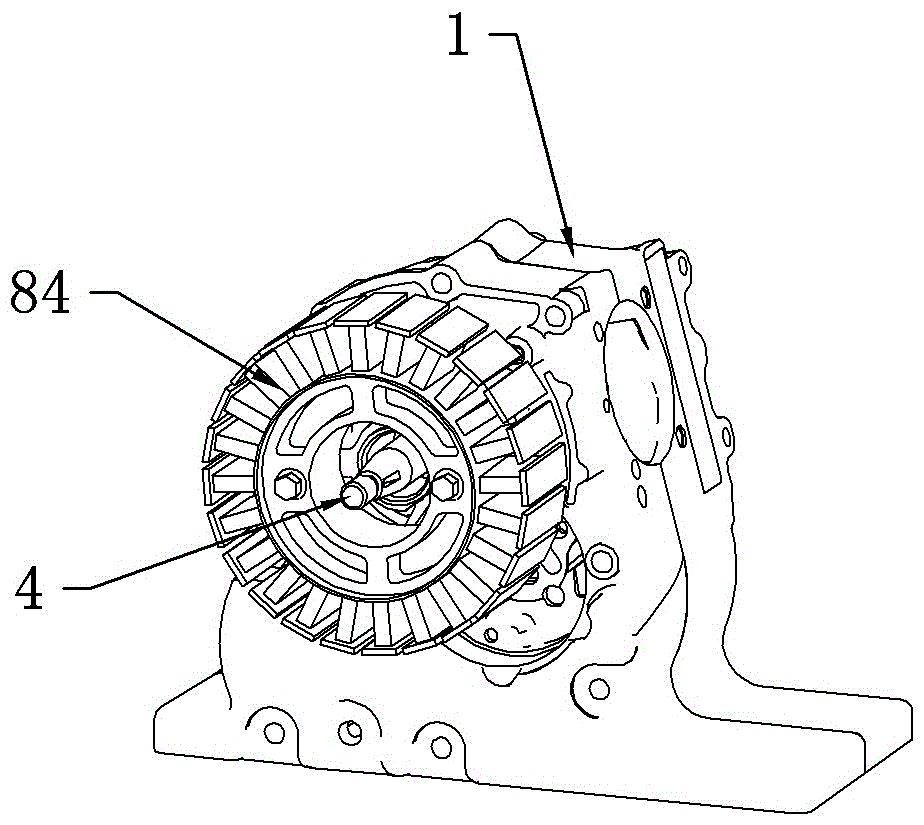

[0035] In this embodiment, the reference signs are respectively: crankcase 1, left casing 11, right casing 12, connecting end surface 13, cylinder body 2, cylinder head 3, oil outlet 31, cooling air duct 32, cooling chamber 33. Exhaust outlet 34, air outlet 35, air inlet 36, air inlet 37, baffle 38, crankshaft 4, connecting rod 41, connecting rod small head 411, shaft 412, connecting rod big head 413, cooling fan 5. Air guide cover 6, gas distribution mechanism 7, camshaft 71, rocker arm 72, cam 73, timing gear 74, intake valve 76, exhaust valve 75, power generation structure 8, flywheel 81, ventilation hole 812, limiter Position hole 812, cylinder 82, permanent magnet 83, stator 84, magnet guard ring 85, limit bar 851, ring 852, protrusion 853, rotor type oil pump 9.

[0036] Such as figure 1 As shown, a general-purpose high-speed engine includes a crankcase 1, a cylinder body 2 and a cylinder head 3 connected in sequence, a crankshaft 4 mechanism, a gas distribution mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com