Method for visibly detecting storage stability change of protein bar

A protein bar and stability technology, which is applied in the field of monitoring protein bar storage stability changes by using fluorescent bleaching recovery technology, and can solve problems such as unclear hardening mechanism and texture hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for visually detecting changes in storage stability of protein bars, the technical solution adopted is:

[0034] 1) Preparation of casein bar model system

[0035] 2.5 g of sorbitol was dissolved in 1.25 g of ultrapure water, and 1.75 g of glycerin was added and stirred. After stirring evenly, the mixture was mixed with 4.5g sodium caseinate for 2min, and kneaded into a uniform dough. Finally, the kneaded dough was sealed with parafilm to prevent water from evaporating and placed in a 3 ) 2 In the desiccator of the supersaturated solution (a w =0.53) to be determined. After the airtight container was equilibrated at room temperature for 0.5h, the 0d sampling was carried out.

[0036] 2) Sample fluorescence staining

[0037] A 0.2 mg / mL fluorescein isothiocyanate (FITC) / acetone staining solution was prepared, and 6 μg of the staining solution was added dropwise to 0.5 g of sodium caseinate dough and mixed. After mixing evenly, 0.3g of the dyed sodium case...

Embodiment 2

[0041] A method for visually detecting changes in storage stability of protein bars, the technical solution adopted is:

[0042] 1) Preparation of whey protein bar model system

[0043] 2.5 g of sorbitol was dissolved in 1.25 g of ultrapure water, and 1.75 g of glycerin was added and stirred. After stirring evenly, the mixture was mixed with 4.5g of whey protein for 2min, and kneaded into a uniform dough. Finally, the kneaded dough was sealed with parafilm to prevent water from evaporating and placed in a 3 ) 2 In the desiccator of the supersaturated solution (a w =0.53) to be determined. After the airtight container was equilibrated at room temperature for 0.5h, the 0d sampling was carried out.

[0044] 2) Sample fluorescence staining

[0045] With embodiment 1.

[0046] 3) Fluorescent bleaching recovery assay

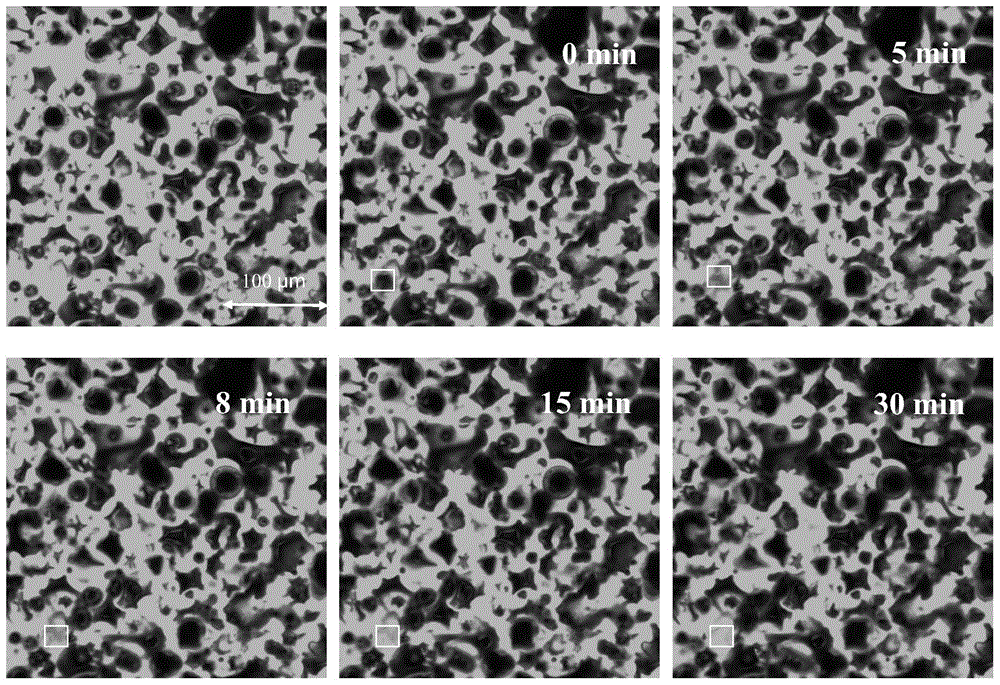

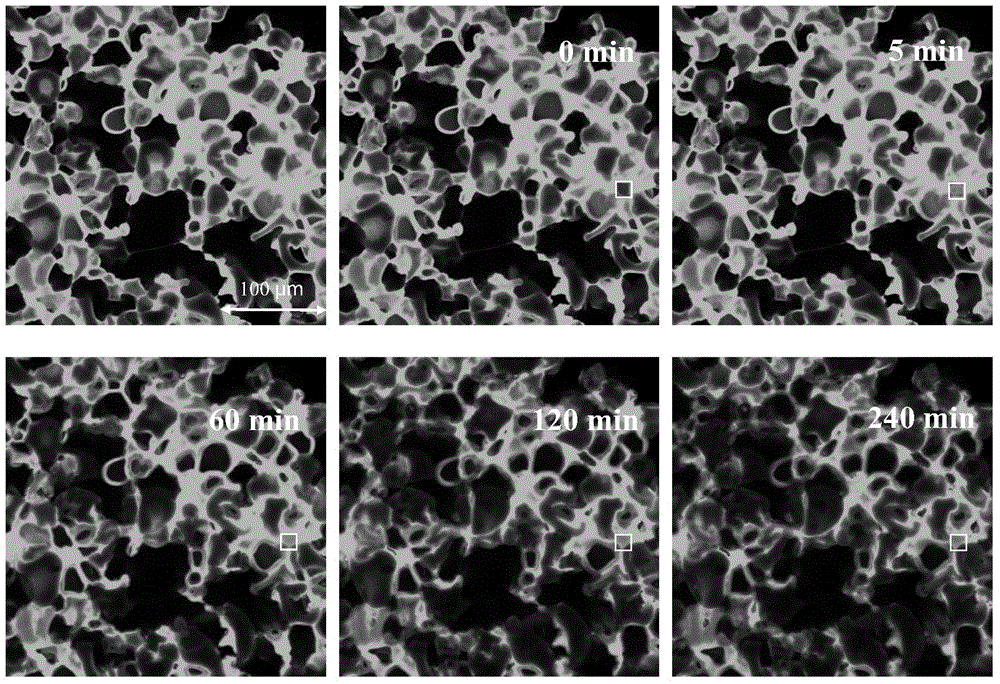

[0047] With embodiment 1. The experimental results are shown in Figure 2. Figure 2A The shown whey protein bar model system completed fluorescence bleachin...

Embodiment 3

[0049] A method for visually detecting changes in storage stability of protein bars, the technical solution adopted is:

[0050] 1) Preparation of concentrated milk protein bar model system

[0051] 2.5 g of sorbitol was dissolved in 1.25 g of ultrapure water, and 1.75 g of glycerin was added and stirred. After stirring evenly, the mixture was mixed with 4.5g of concentrated milk protein for 2min, and kneaded into a uniform dough. Finally, the kneaded dough was sealed with parafilm to prevent water from evaporating and placed in a 3 ) 2 In the desiccator of the supersaturated solution (a w =0.53) to be determined. After the airtight container was equilibrated at room temperature for 0.5h, the 0d sampling was carried out.

[0052] 2) Sample fluorescent staining

[0053] With embodiment 1.

[0054] 3) Fluorescent bleaching recovery assay

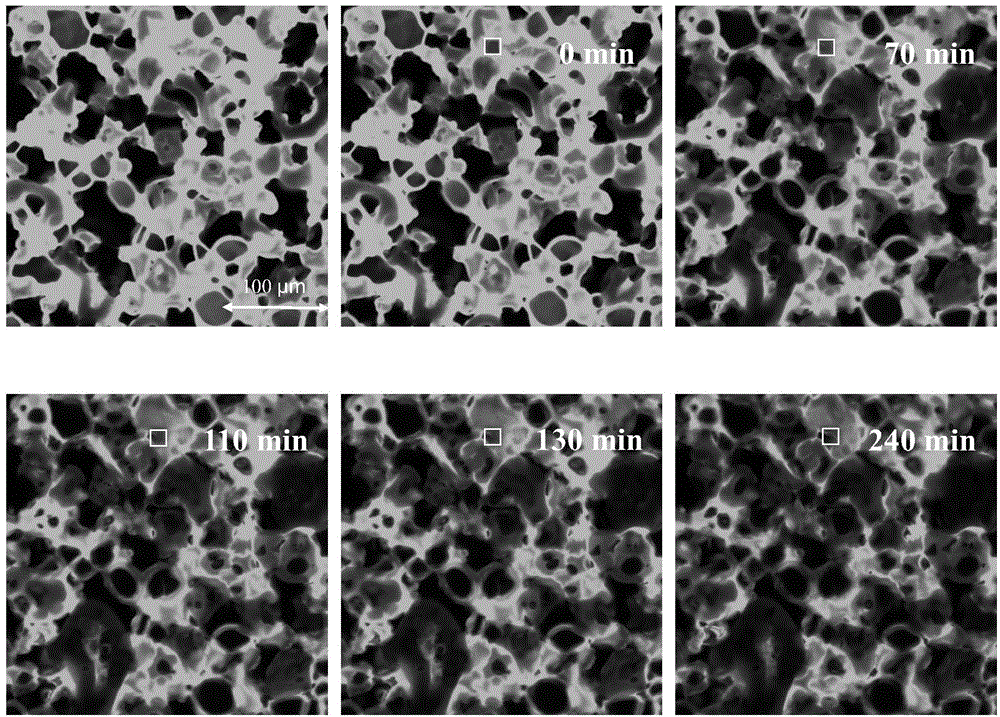

[0055] With embodiment 1. The experimental results are shown in Figure 3. Figure 3A The concentrated milk protein bar model system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com