Frozen fresh meat preservative film and preparation and application method thereof

A technology of chilled meat and fresh-keeping film, applied in transportation and packaging, flexible coverings, packaging, etc., can solve the problems of incomplete inhibition of growth and reproduction, browning of the surface of chilled meat, unfavorable long-distance transportation, etc., and achieve raw material prices Low cost, stable product performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of plastic wrap: (1) Weigh 30 parts of food-grade polyvinyl alcohol into a flask, add distilled water, stir in a water bath at 90°C for 1 hour to dissolve completely, and set aside.

[0031] (2) Weigh 60 parts of glutinous rice flour, 10 parts of glycerin, 0.05 part of nisin, and 0.02 part of TBHQ, stir and mix for 5 minutes. Mix well and set aside.

[0032] (3) Add the sample mixed in (2) to (1), stir continuously in a constant temperature water bath at 70°C, and react for 1 hour. After cooling to 60-70°C, the film solution was obtained and set aside.

[0033] (4) Pour (3) medium film solution into a polyethylene tray with a thickness of 1mm, and dry it at 50°C to form a fresh-keeping film for chilled meat.

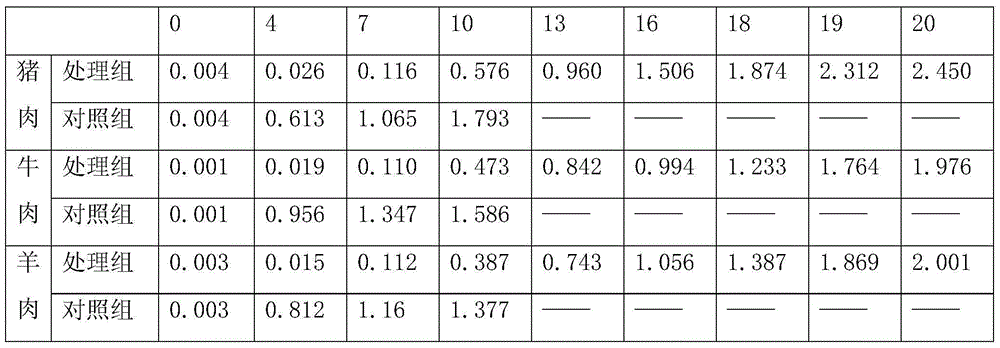

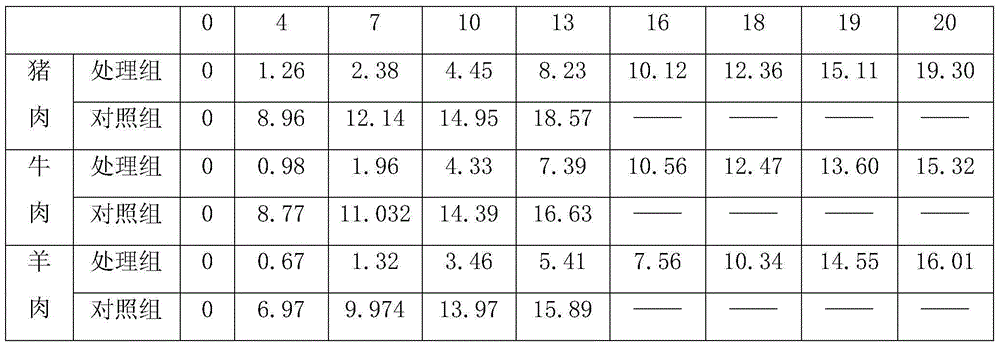

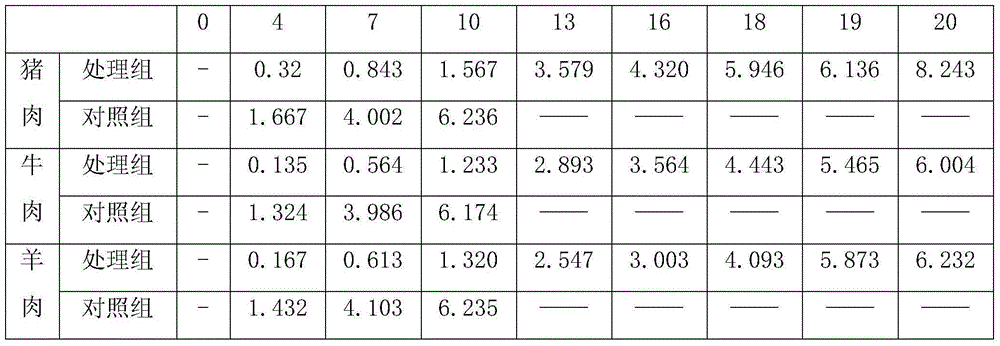

[0034] 2. How to use fresh-keeping film for chilled meat: (1) Cut the size of the plastic wrap according to the volume of chilled pork, beef, and mutton, and set aside. (2) Wrap the chilled meat skin-to-body with the plastic wrap in (1), place the...

Embodiment 2

[0043] 1. Preparation of plastic wrap: (1) Weigh 40 parts of food-grade polyvinyl alcohol into a flask, add distilled water, stir in a water bath at 80°C for 1 hour to dissolve completely, and set aside.

[0044] (2) Weigh 58 parts of glutinous rice flour, 2 parts of glycerin, 0.02 part of nisin, and 0.01 part of TBHQ, stir and mix for 6 minutes. Mix well and set aside.

[0045] (3) Add the sample mixed in (2) to (1), stir continuously in a constant temperature water bath at 75°C, and react for 1 hour. After cooling to 60-70°C, the film solution was obtained and set aside.

[0046] (4) Pour (3) medium film solution into a polyethylene tray with a thickness of 1.5mm, and dry it at 55°C to form a fresh-keeping film for chilled meat.

[0047] 2. How to use fresh-keeping film for chilled meat: (1) Cut the size of the plastic wrap according to the volume of chilled pork, beef, and mutton, and set aside. (2) Wrap the chilled meat skin-to-body with the plastic wrap in (1), place th...

Embodiment 3

[0050]1. Preparation of plastic wrap: (1) Weigh 50 parts of food-grade polyvinyl alcohol into a flask, add distilled water, stir in a water bath at 90°C for 0.5h to dissolve completely, and set aside.

[0051] (2) Weigh 46 parts of glutinous rice flour, 4 parts of glycerin, 0.01 part of nisin, and 0.02 part of TBHQ, stir and mix for 8 minutes. Mix well and set aside.

[0052] (3) Add the sample mixed in (2) to (1), stir continuously in a constant temperature water bath at 80°C, and react for 1 hour. After cooling to 60-70°C, the film solution was obtained and set aside.

[0053] (4) Pour (3) medium film solution into a polyethylene tray with a thickness of 1.5mm, and dry it at 50°C to form a fresh-keeping film for chilled meat. 2. How to use fresh-keeping film for chilled meat: (1) Cut the size of the plastic wrap according to the volume of chilled pork, beef, and mutton, and set aside. (2) Wrap the chilled meat skin-to-body with the plastic wrap in (1), place the transfer p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com