Highly integrated grooved insulated gate tunneling bipolar enhancement transistor and its manufacturing method

An insulated gate and transistor technology, which is applied in the field of highly integrated groove insulated gate tunneling bipolar enhanced transistors and their manufacturing, can solve the problems of small forward conduction current, increased process difficulty, deterioration of device switching characteristics, etc., and achieves high integration degree, saving chip area, and the effect of excellent switching characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, the present invention will be further described:

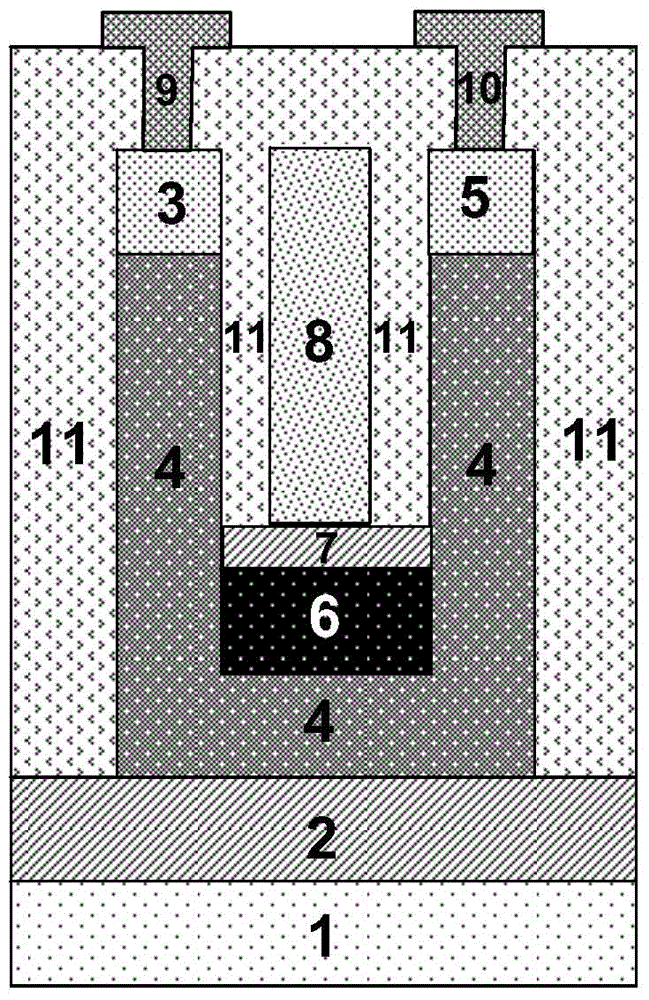

[0049] Such as figure 1 It is a schematic diagram of a two-dimensional structure of a highly integrated grooved insulated gate tunneling bipolar enhancement transistor formed on an SOI substrate according to the present invention; it specifically includes a single crystal silicon substrate 1; a wafer insulating layer 2; an emitter region 3; a base region 4; Collector region 5; conductive layer 6; tunnel insulating layer 7; gate electrode 8; emitter 9; collector 10; blocking insulating layer 11.

[0050] Highly integrated grooved insulated gate tunneling bipolar enhancement transistor, using a bulk silicon wafer containing only a single crystal silicon substrate 1 as a device substrate, or using a bulk silicon wafer containing both a single crystal silicon substrate 1 and a wafer insulating layer 2 The SOI wafer is used as the substrate for generating devices; the base regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com