Fuel-cell tail gas circulation system

A circulation system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of hindering the transition of hydrogen-air fuel cells, complex structure of external humidification system, difficult control, etc., and achieve easy approval Promotion of production, reduction of power generation costs, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

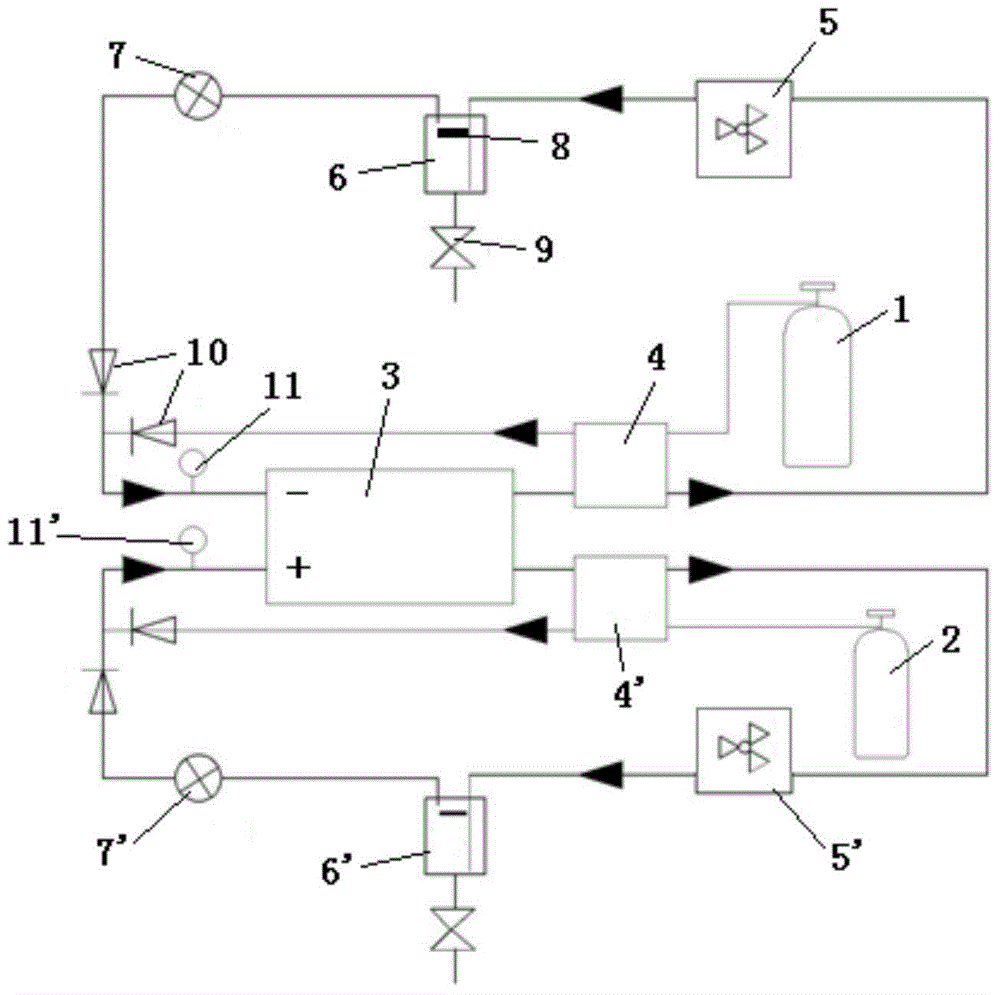

Embodiment 1

[0028] In Example 1, the oxidant gas is oxygen, that is, the fuel cell is a hydrogen-oxygen fuel cell. For the tail gas circulation system of this embodiment, the cathode side is used for circulating oxygen, and the anode side is used for circulating hydrogen; structurally, the structure and composition of the cathode side and the anode side are symmetrical, and only the structure of the cathode side will be specifically described below, namely Each device in the structure of the cathode side described below is also provided correspondingly on the anode side, and works in the same way.

[0029] In the self-heating part, the first heat exchanger 4 has two gas pipelines, which are respectively connected to the cathode tail end of the fuel cell stack 3 and the outlet end of the oxidant gas tank 1 (it can also be other oxidant supply equipment). The cathode tail gas that has reacted in the fuel cell stack 3 and the oxygen used to enter the fuel cell stack 3 for reaction will all p...

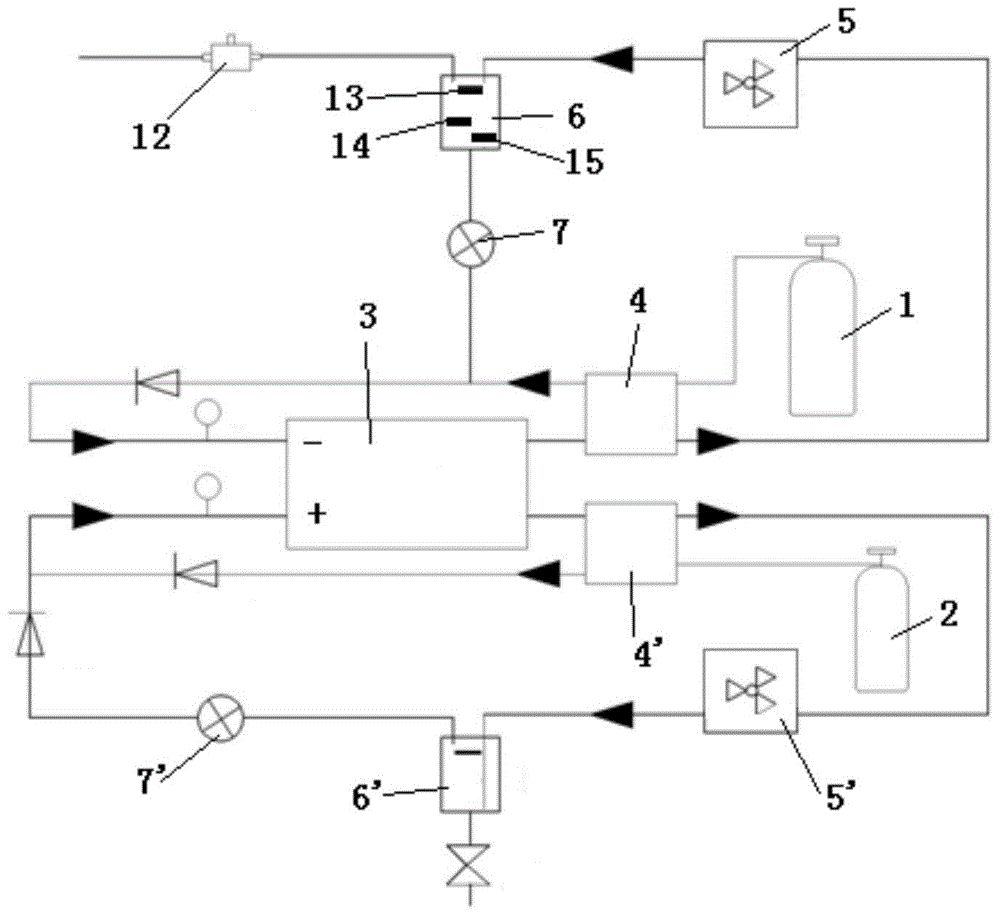

Embodiment 2

[0040] In Example 2, the oxidant gas is air, that is, the fuel cell is a hydrogen-air fuel cell.

[0041] For the exhaust gas circulation system of this embodiment, the cathode side is used to circulate air and recover the water generated by the stack to humidify the reaction air, and the anode side is used to circulate hydrogen while recovering the water generated by the stack to humidify the reaction hydrogen; the structural composition and implementation of the anode side In Example 1, the structure of the anode side is the same, but the structure of the cathode side is different, so only the structure of the cathode side will be described in detail below.

[0042] In embodiment 2, due to the reduction of the oxygen concentration in the tail gas, the cathode side structure is different compared to embodiment 1. Specifically, the first circulation pump 7 is a water pump; the first gas / water separator 6 includes an exhaust end (at the upper end), a solenoid valve at the drain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com