LED dimming system

A dimming and dimmer technology, applied in the field of LED dimming systems, can solve the problems of low efficiency of dimming systems, difficulty in networking, and easy noise generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

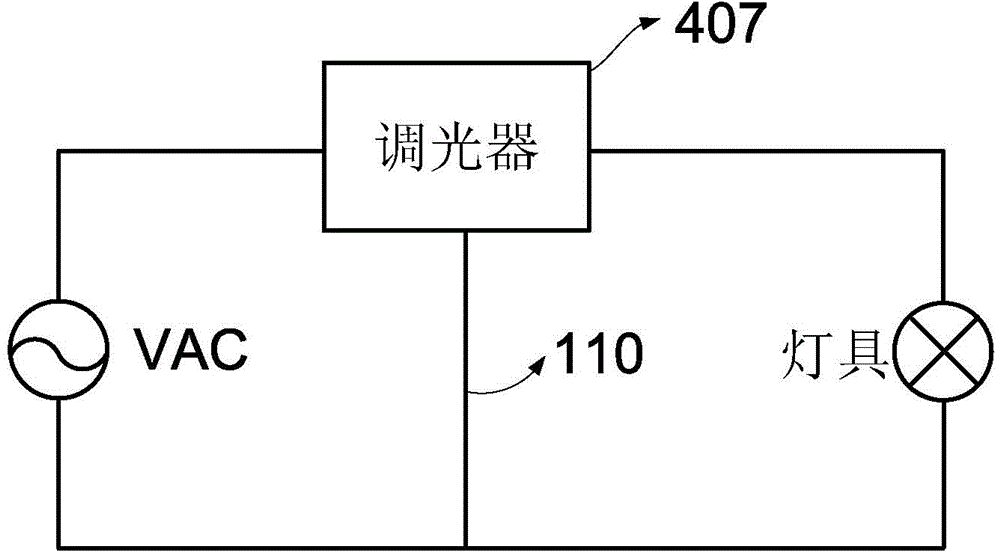

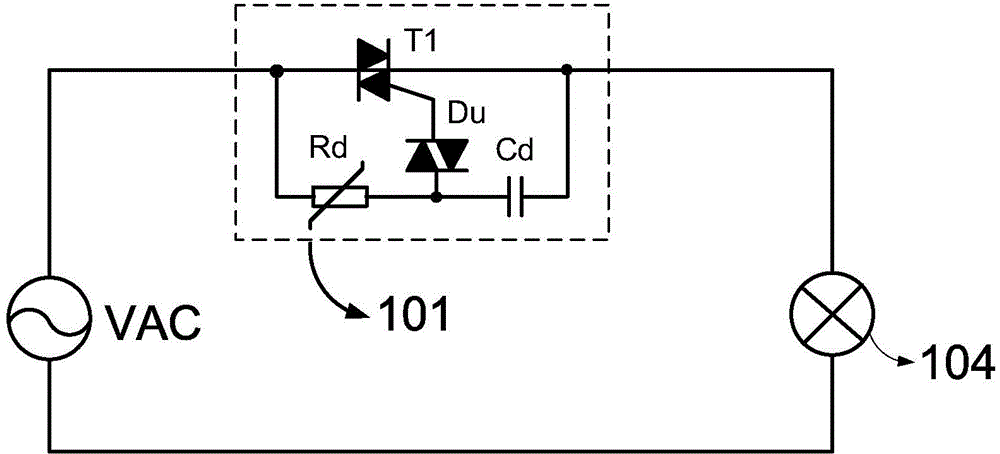

[0103] refer to Figure 6 , the LED dimming system of this embodiment includes: an AC input power supply VAC, a control unit 407 and a load device 400 .

[0104] Wherein, the load device 400 may include: a rectification circuit 401 , an EMI filter circuit 408 , a bypass circuit 402 , a zero-crossing detection circuit 403 , a data sampling circuit 404 , a controller 405 and a power conversion circuit 406 . Wherein, the controller 405 may be implemented by a microcontroller (MCU) or other appropriate components.

[0105] Preferably, the load device 400 can be integrated inside the lamp, in other words, the load device 400 can be integrated with the lamp.

[0106] Further, the AC input power supply VAC has an AC input first terminal and an AC input second terminal, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com