Preparation method of organic mineral complex, curable composition, cured product of curable composition, hard coating material, hard coating film and silane coupling agent

A technology of silane coupling agent and manufacturing method, which is applied in the field of hard coating film, silane coupling agent and cured product, can solve the problems of roll-up (curling, large curing shrinkage rate, cracks in hard coating film, etc.), and achieve durability Excellent abrasion resistance and excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0168] Examples and comparative examples are shown below to explain the present invention in more detail.

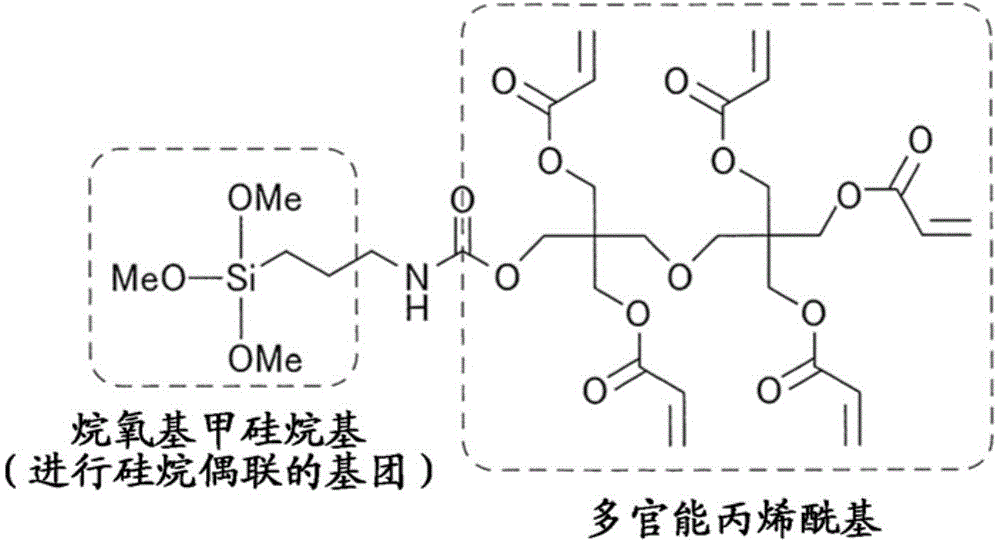

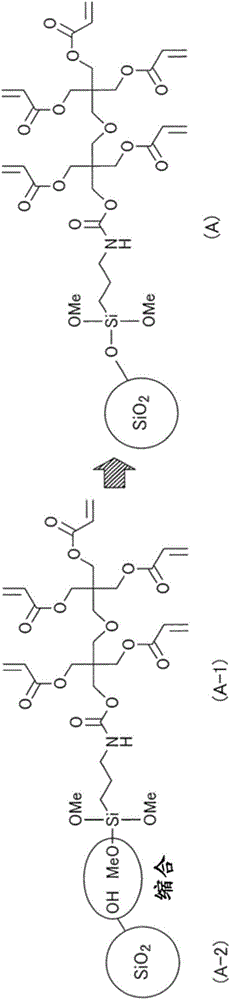

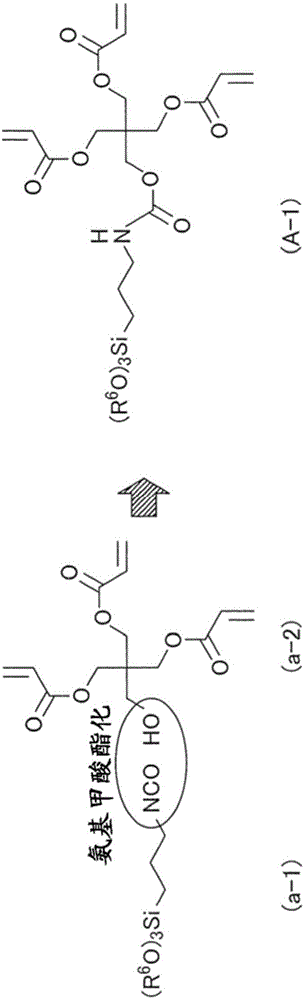

[0169] (1) Synthesis of silane coupling agent (inorganic oxide particle modifier) having at least 2 acryloyl groups

Synthetic example 1

[0170] [Synthesis Example 1]: Synthesis of Inorganic Oxide Microparticle Modifier (D-1)

[0171] In a detachable flask, 129.2 g of toluene as a reaction solvent, and a reaction product of dipentaerythritol and acrylic acid (46.7% by mass of dipentaerythritol pentaacrylate, dipentaerythritol pentaacrylate, dipentaerythritol A mixture of 23.1% by mass of tetraacrylate, 27.9% by mass of dipentaerythritol hexaacrylate, and 2.3% by mass of other unknown substances; 100 g of DPPA mixture a, hydroxyl value 101), heated while stirring so that the internal temperature of the detachable flask became 50 °C to make a homogeneous solution.

[0172] Next, 29.2 g of 3-isocyanatopropyl triethoxysilane (trade name KBE-9007; manufactured by Shin-Etsu Chemical Co., Ltd.) as an isocyanate compound (isocyanate group-containing compound) having an alkoxysilyl group, With 0.58 g of zirconium tetraacetylacetonate (trade name ZC-700: manufactured by Matsumoto Fain Chemical Co., Ltd., non-volatile con...

Synthetic example 2

[0174] [Synthesis Example 2]: Synthesis of Inorganic Oxide Microparticle Modifier (D-2)

[0175] Except for changing the usage-amount of each compound as shown in Table 1, the same operation as Synthesis Example 1 was carried out to obtain 571 g of a 50.6% by mass non-volatile matter toluene solution of the inorganic oxide fine particle modifying agent (D-2).

[0176] [Table 1]

[0177]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com