Stabilized coating for surface rust layer of weatherproof steel

A weathering steel and coating technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of unsuitable on-site practical application, cumbersome process, high temperature curing of coating film, etc. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below by embodiment the present invention will be further described.

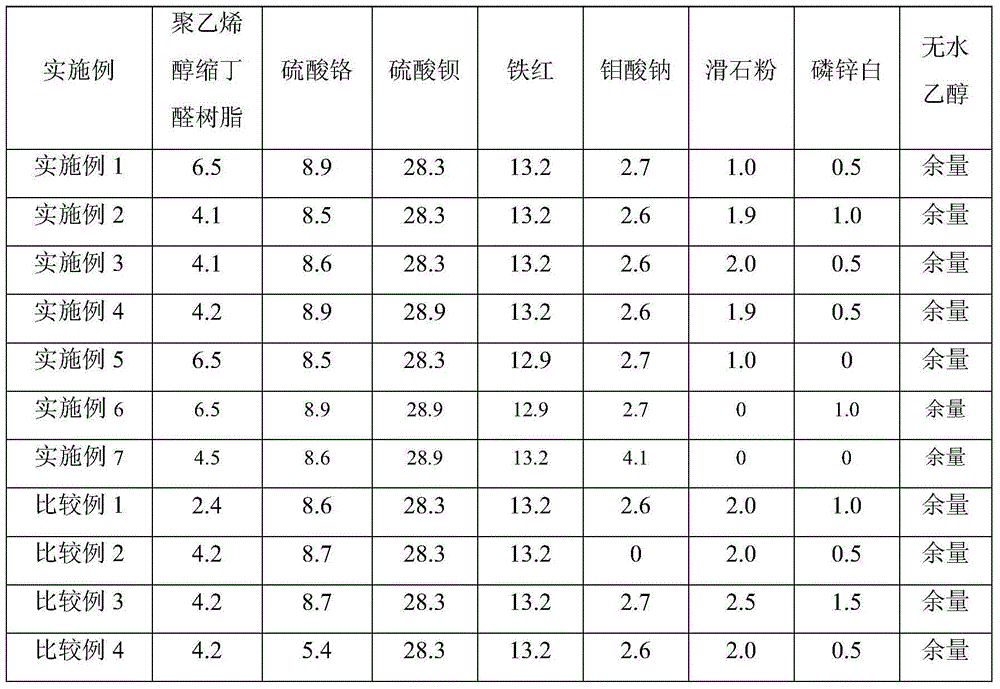

[0016] The weathering steel used in the test is Q690qE weathering steel for bridges. Examples and comparative examples of weathering steel surface stabilization coatings of the present invention are shown in Table 1. The performance of the coating was evaluated after the coating was applied and cured. The performance evaluation results of the coating of the present invention are shown in Table 2.

[0017] Table 1 Embodiment and comparative example (mass%) of weathering steel surface stabilization coating of the present invention

[0018]

[0019] Remarks: The balance is absolute ethanol as the solvent.

[0020] Table 2 coating performance evaluation result of the present invention

[0021] Example

[0022] The actual drying time of the coating is measured according to the blade method in GB1728-1979 "Determination of Drying Time of Paint Film and Putty Film"; the coating adhesion tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com