Method for preparing rare earth oxalate precipitation

A technology for rare earth and oxalic acid, applied in the field of preparing rare earth oxalate precipitation, can solve the problems of rare earth precipitation throwing out the machine, physical injury of operators, increase production cost, etc., and achieve the effects of shortening production cycle, saving burning energy and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

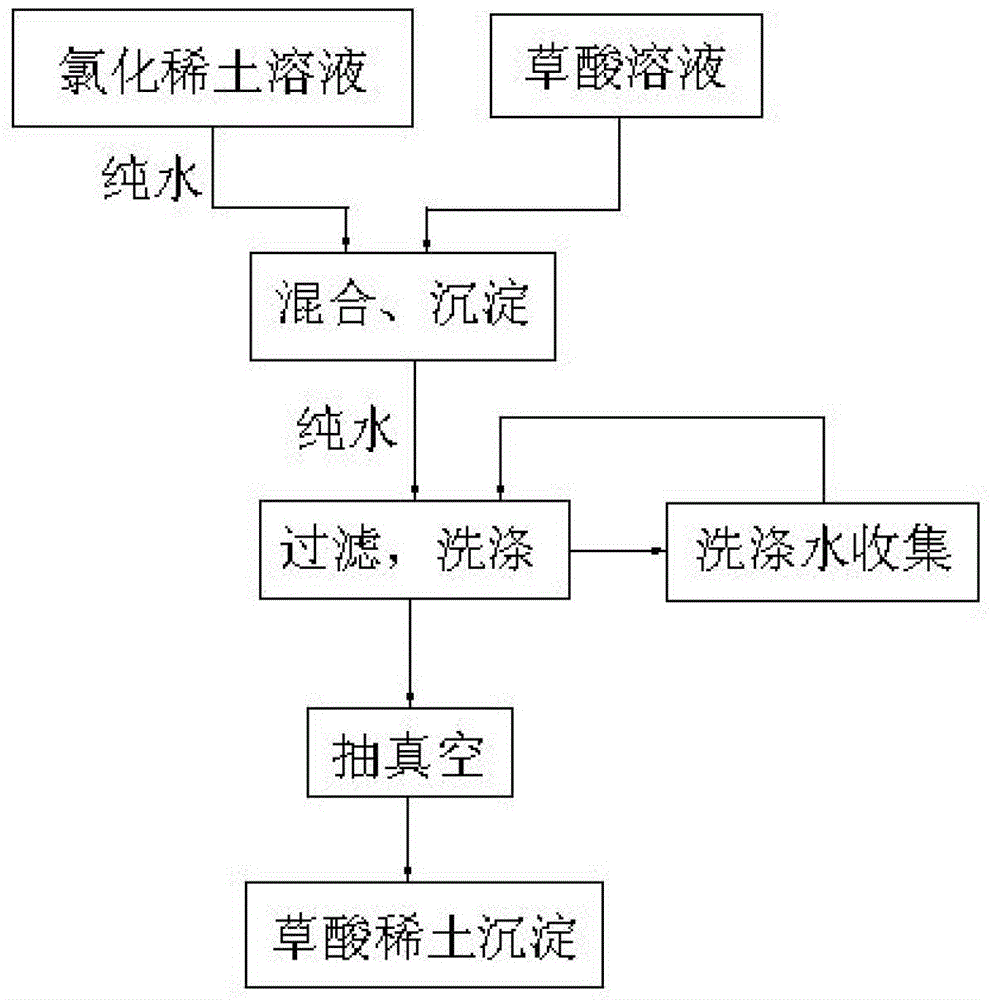

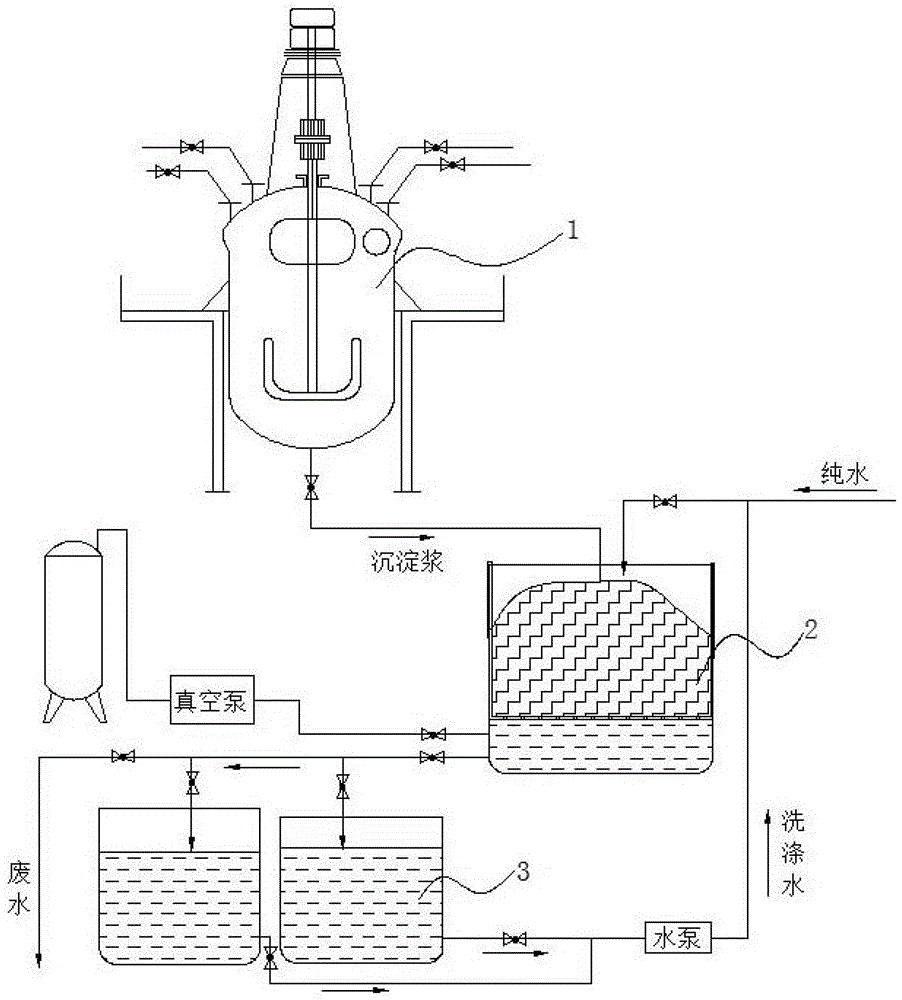

[0027] See figure 1 with figure 2 , figure 1 Prepare the process flow chart of the method for rare earth oxalate precipitation for the present invention, figure 2 It is a schematic diagram of the equipment structure of the method of the present invention, and the process of the present invention comprises the following steps:

[0028] (1) Add hot water at 70-80°C to the precipitation tank 1 to preheat the interior of the precipitation tank 1; then simultaneously feed the heated oxalic acid solution prepared with refined oxalic acid and pure water and the rare earth extraction and separation preparation Chloride the rare earth solution, and turn on the stirring device, so that the oxalic acid and the rare earth chloride fully react to form a rare earth oxalate precipitate; the concentration of the rare earth chloride solution is 1.5~2.0mol / L, the concentration of the oxalic acid solution is 180g / L, and the reaction temperature is 70 ~80°C. Refined oxalic acid is refined f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com