Manufacturing method for fin on insulator

A technology of insulators and fins, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of fragile fins, easy to break, difficult to control the height of fins, etc., and achieve the effect of improving device performance and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

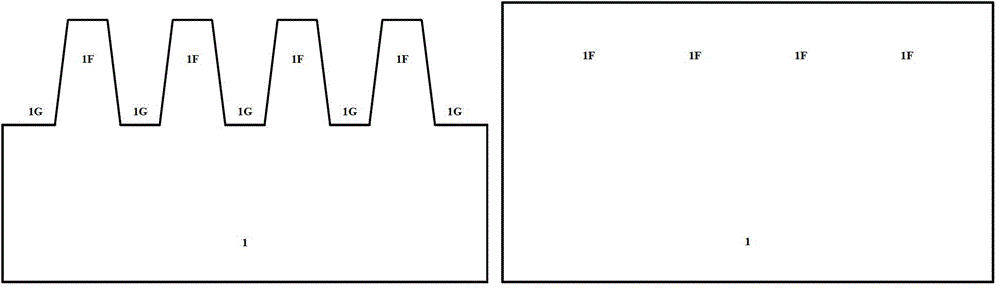

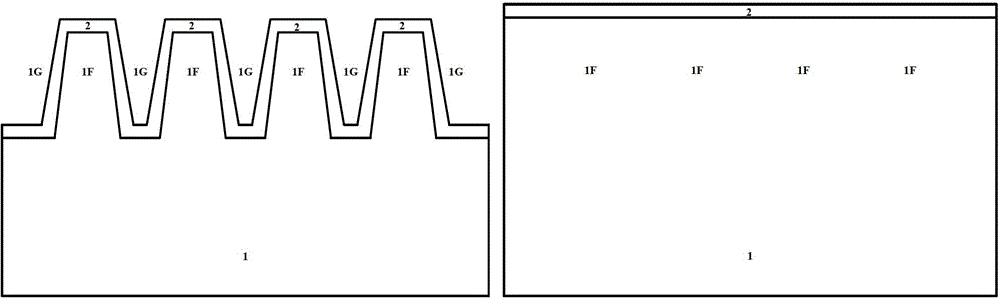

[0029] The features and technical effects of the technical solution of the present invention will be described in detail below with reference to the accompanying drawings and in conjunction with schematic embodiments, which discloses the fins on the insulator that can effectively improve the fineness of the fins and improve the insulation and isolation effect between the fins. Manufacturing method. It should be pointed out that similar reference numerals represent similar structures, and the terms "first", "second", "upper", "lower" and the like used in this application can be used to modify various device structures or manufacturing processes . These modifications do not imply spatial, sequential or hierarchical relationships of the modified device structures or fabrication processes unless specifically stated.

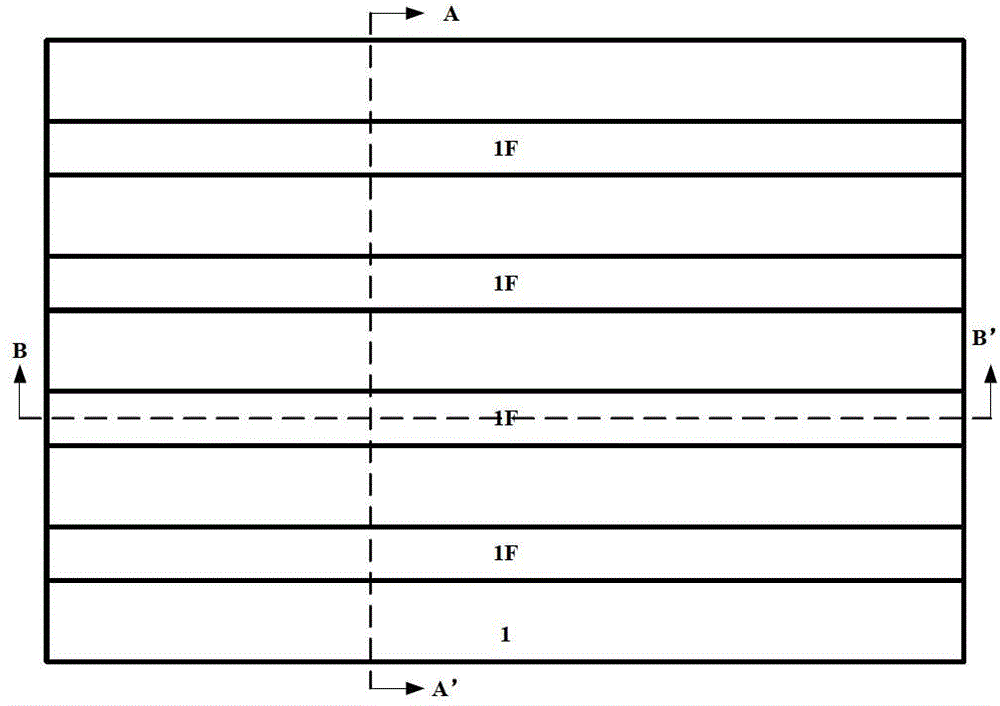

[0030] figure 1 Shown is the top view of the FinFET and tri-gate device in the prior art and the present invention, including the substrate 1 and the fin 1F formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com