Super-deep bed filter with external circulating cleaning function

An in vitro cleaning and filter technology, which is applied in the direction of gravity filter, loose filter material filter, filter separation, etc., can solve the problems of inability to use filter treatment, short service life of filter material, low filtration precision, etc., and achieve flexible design , save equipment cost, and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

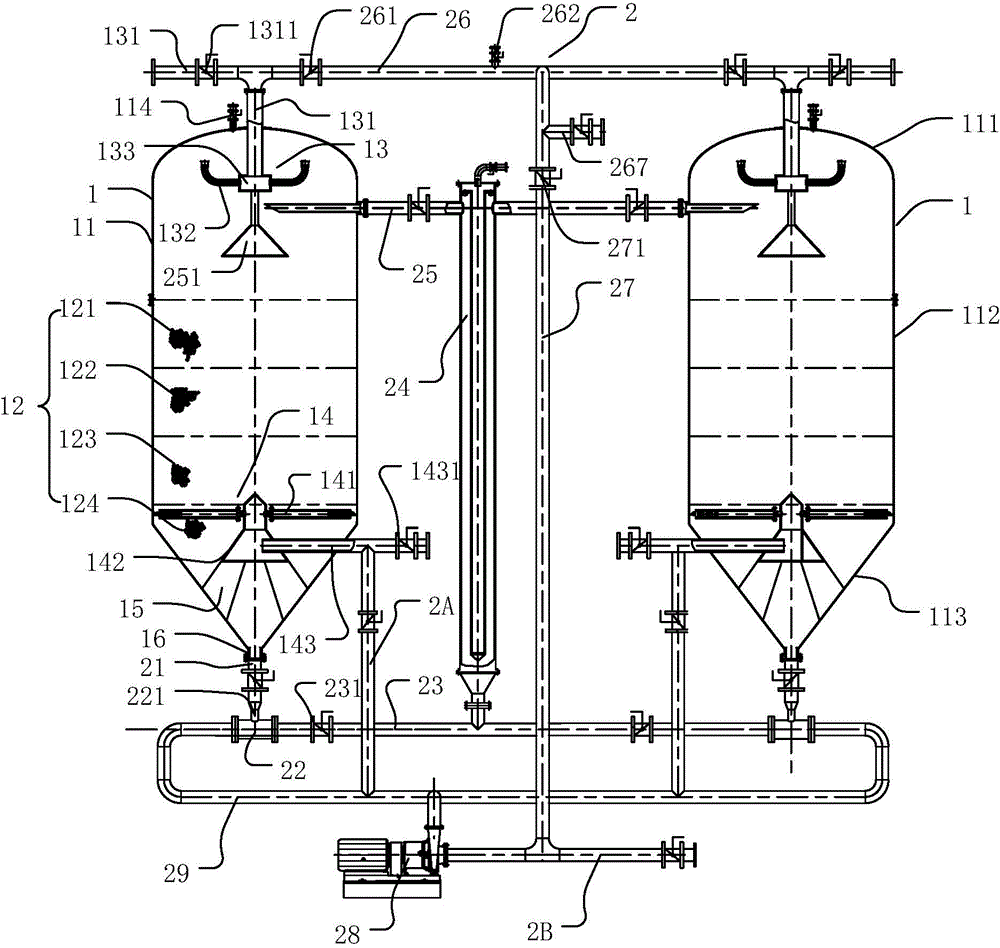

[0039] Such as figure 1 As shown, the filter in this embodiment includes a filter body 1 and an extracorporeal cleaning cycle device 2 . The filter body 1 includes a filter tank body 11 , a filter material 12 , an upper pipeline 13 and a lower pipeline 14 , and the filter tank body 11 includes an upper head 111 , a cylinder body 112 and a lower conical head 113 . The upper head 111 , the cylinder body 112 and the lower conical head 113 are connected to each other in order from top to bottom to form the filter tank body 11 . On the upper end of the canister body 11 is provided a canister oil discharge pipe 114 . The filter material 12 includes a top filter material 121 , a middle filter material 122 , a bottom filter material 123 (or more layers of filter material) and a mixed filter material 124 . These filter materials are sequentially placed in the filter tank body 11 from top to bottom to filter the fluid to be filtered passing through the filter tank body 11 .

[0040] ...

Embodiment 2

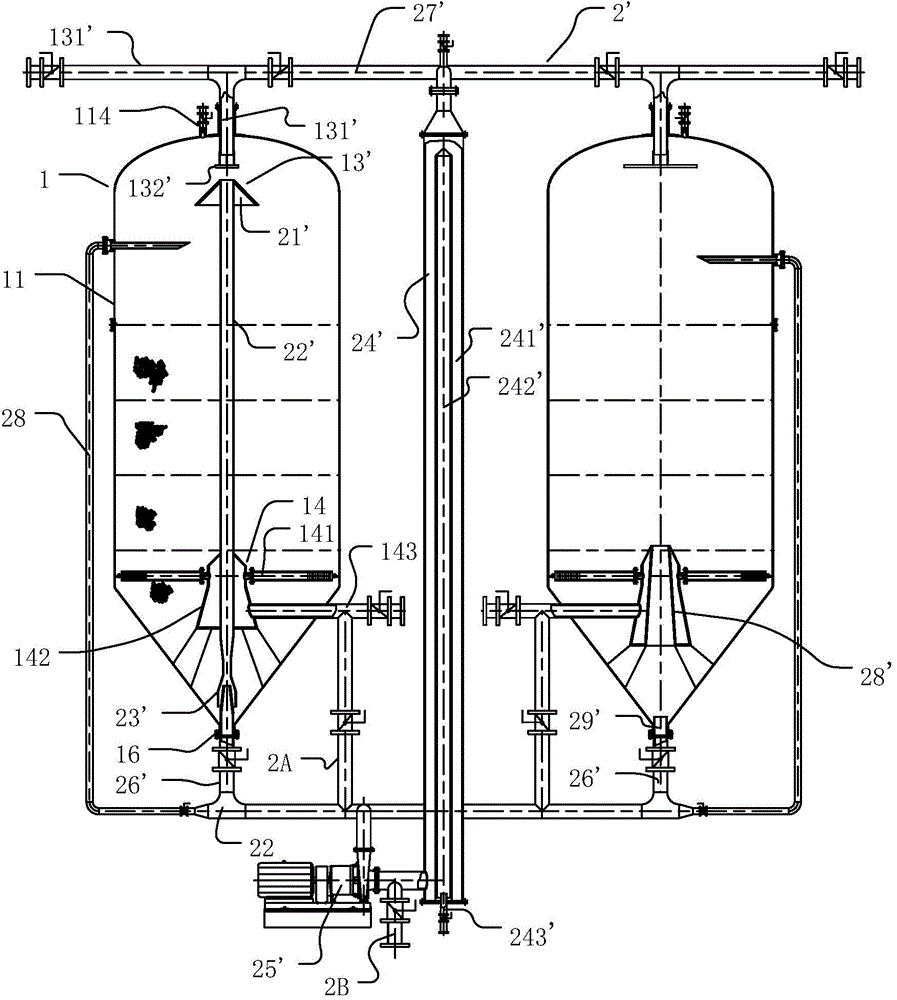

[0049] The filter in the second embodiment includes a filter body 1' and an extracorporeal cleaning circulation device 2'. The filter body 1' has the same structure as the filter body 1 in the first embodiment except for the upper pipeline, and the same parts are here Do not repeat. The upper pipeline in this embodiment is represented by 13'; the extracorporeal cleaning and circulatory device in this embodiment is also different from the extracorporeal cleaning and circulatory device 2 in Embodiment 1, and the extracorporeal cleaning and circulatory device in this embodiment is represented by 2' To represent. The upper pipeline 13' and the extracorporeal cleaning and circulation device 2' in the second embodiment will be introduced respectively below.

[0050] Such as figure 2 As shown, the upper pipeline 13' includes a liquid inlet pipe 131' and a water distribution baffle 132', the liquid inlet pipe 131' is inserted from the top of the filter tank body 11, and the water d...

Embodiment 3

[0056] The third embodiment is basically the same as the second embodiment, and the difference between the third embodiment and the second embodiment will be described in detail below. Embodiment 3 On the basis of Embodiment 2, the guide umbrella 21', the material guide pipe 22' and the jet device 23' are canceled, and the jet guide hole 28' is set along the longitudinal center position of the central water collecting tube 142, and the backwashing into One end of the water pipe 26' facing the inside of the filter tank body 11 is provided with an inlet nozzle 29', and the spraying direction of the inlet nozzle 29' is directly opposite to the inlet end of the jet guide hole 28'.

[0057] The operation processes of the third embodiment and the second embodiment are basically the same, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com