PEO-b-PMMA modified PVDF ultrafiltration membrane and preparation process thereof

An ultrafiltration membrane, peo-b-pmma technology, applied in the field of block copolymer PEO-b-PMMA modified polyvinylidene fluoride ultrafiltration membrane and its preparation, to achieve good thermal stability, continuous and convenient operation, durable The effect of corrosion interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

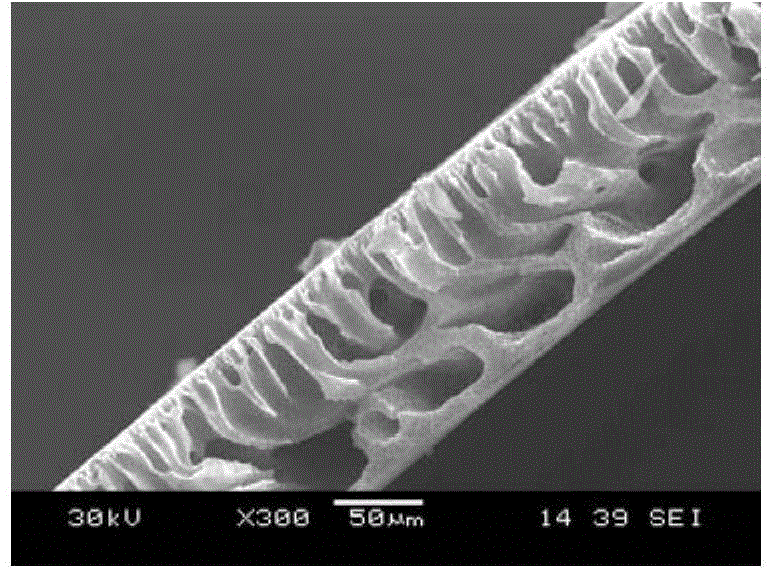

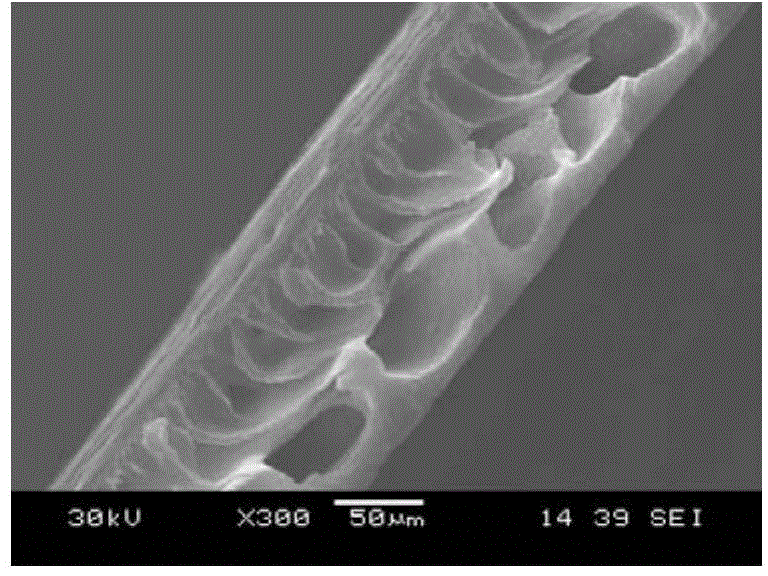

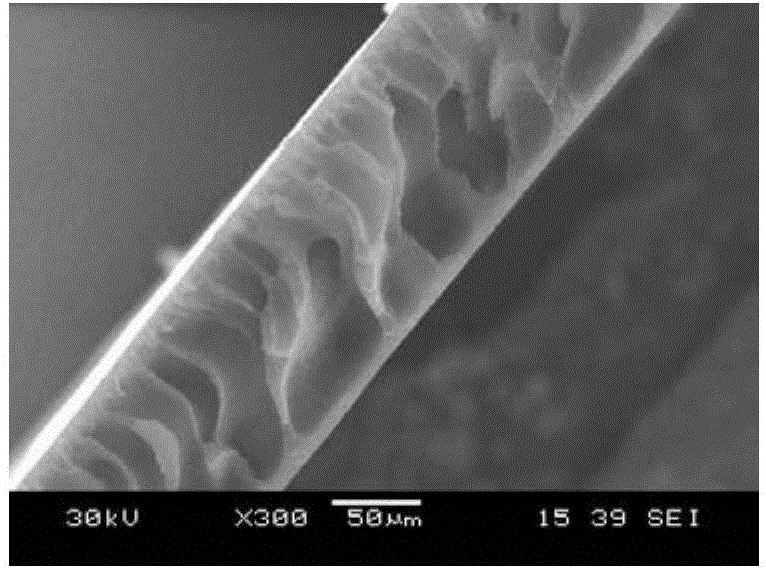

Image

Examples

Embodiment 1

[0033] Weigh 2.5g of PEO-Br, 0.05g of CuCl, 0.22g of PMDETA, 10ml of MMA and 20ml of THF into a 150ml Erlenmeyer flask, and bubble with nitrogen for 30 minutes to remove the air. Then seal it and put it in an oil bath at 60°C and stir for 5h. Cool to room temperature after stirring, add 50mlTHF to dissolve the product, and the solution passes through Al 2 o 3 column to remove Cu ligands. 200ml of glacial ether was poured into the filtrate to obtain a precipitate. The product was filtered with a water pump and then dried in a vacuum oven at 40°C. This is the surfactant PEO-b-PMMA.

Embodiment 2

[0035] Weigh 4g of PVDF, 0.3g of PVP, 0.2g of PEO-b-PMMA, 16.4ml of DMF in a conical flask, fully stir at 60°C for 7 hours to dissolve completely; Push it into a liquid film with a certain thickness with a film scraper, let it stand in the air for 15-20 seconds, and then immerse it together with the glass plate in a coagulation bath at 22°C. After the ultrafiltration membrane automatically falls off from the scraper plate, put the ultrafiltration The membrane is removed from it, immersed in distilled water, and cut to size for testing.

Embodiment 3

[0037] Weigh 4gPVDF, 0.3gPVP, 0.4gPEO-b-PMMA, 16.2mlDMF in a Erlenmeyer flask, stir thoroughly at 60°C for 7 hours to dissolve completely; Push it into a liquid film with a certain thickness with a film scraper, let it stand in the air for 15-20 seconds, and then immerse it together with the glass plate in a coagulation bath at 22°C. After the ultrafiltration membrane automatically falls off from the scraper plate, put the ultrafiltration The membrane is removed from it, immersed in distilled water, and cut to size for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com