Crystal edge cleaning device

A technology for cleaning equipment and equipment, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using gas flow, etc., can solve problems such as the impact of product yield improvement, difficult product crystal edge quality, etc. degree, improve product yield, and reduce the effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

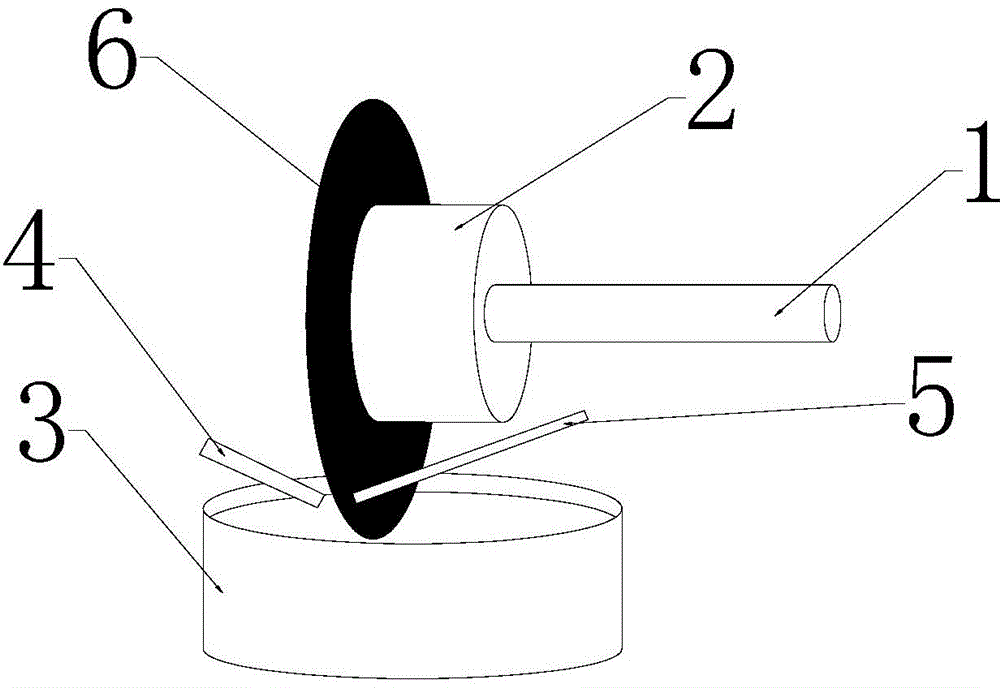

[0017] In view of the current actual production, the crystal edge of the product often becomes the source of defects, so a new equipment is proposed to effectively process the crystal edge in the whole process of production.

[0018] The invention relates to a crystal edge cleaning equipment, comprising a rotating shaft, a wafer clamping device, a cleaning tank and a gas nozzle, the rotating shaft is arranged horizontally, and a driving motor is connected to the rotating shaft, and the rotating shaft is connected to the wafer clamping device Hinged, the first gas nozzle and the second gas nozzle are respectively set on both sides of the wafer clamping device. When cleaning the wafer, the injection point of the first gas nozzle is located at the front edge of the wafer, and the injection point of the second gas nozzle is located at the edge of the wafer. on the opposite edge.

[0019] The specific embodiments of the present invention will be further described below in conjuncti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com