Method for treating phosphorus/phosphine-containing electroplating wastewater by utilizing electroplating sludge

A technology for electroplating wastewater and electroplating sludge, which is applied in the fields of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Excessive cost, waste of resources and other problems, to achieve the effect of improving sludge recycling rate, reducing sludge production and dosage, and improving wastewater reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

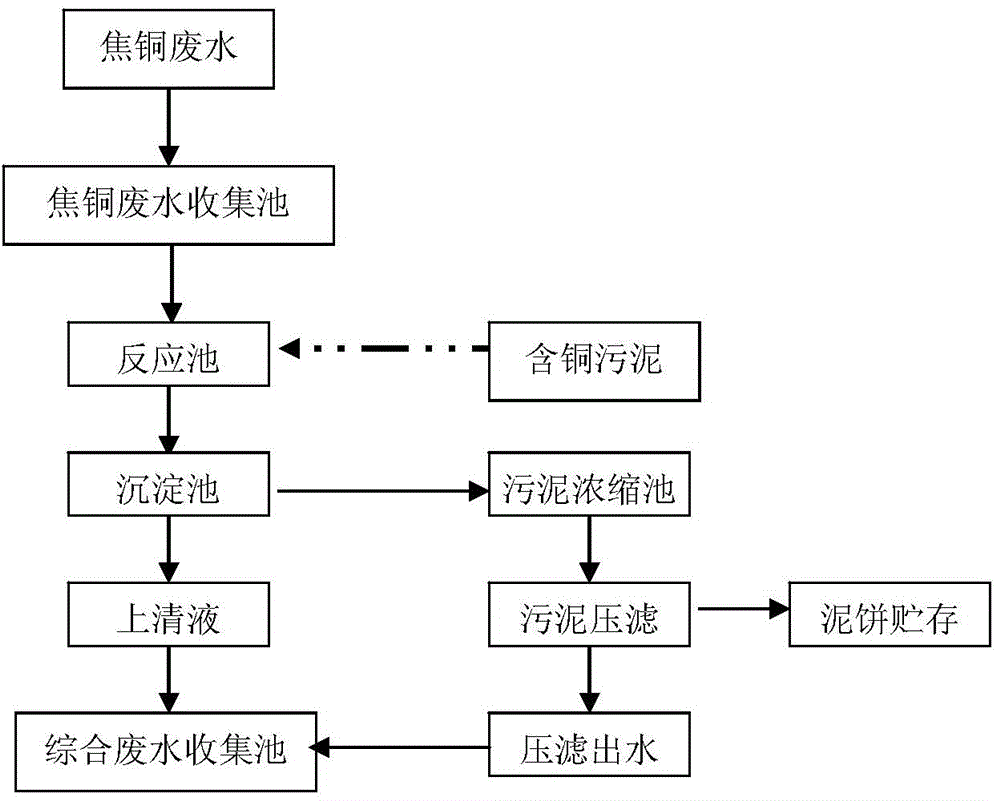

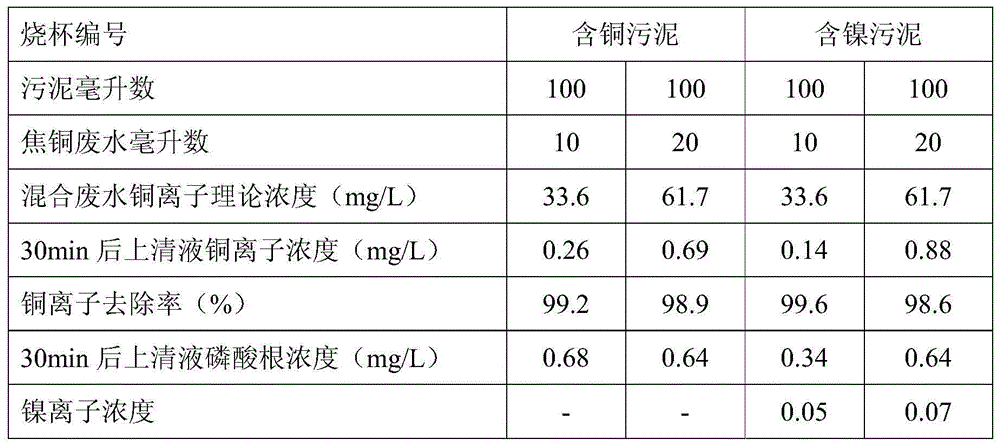

[0033] Coke-containing waste water is collected separately in the coke-copper waste water collection tank, after adjusting the water quality and quantity. Pump the coke copper wastewater into the chromium-containing wastewater sludge concentration tank, pump the wastewater into the depth of 1 / 2 to 3 / 4 of the concentration tank, keep the rising flow rate of the wastewater at 0.25 to 2.5m / h, use a pH meter (pH<8.5 ) to control the pumping volume of coke copper wastewater.

[0034] Batch operation can also be operated continuously to control the ratio of sludge to wastewater to 1:1~1:5. During continuous operation, the pH control solenoid valve controls the amount of sludge pumped.

[0035] The chemical nickel wastewater is pumped into the nickel-containing sludge concentration tank or the comprehensive sludge concentration tank (the ratio of sludge to wastewater is 1:1~1:10, pH>8.5).

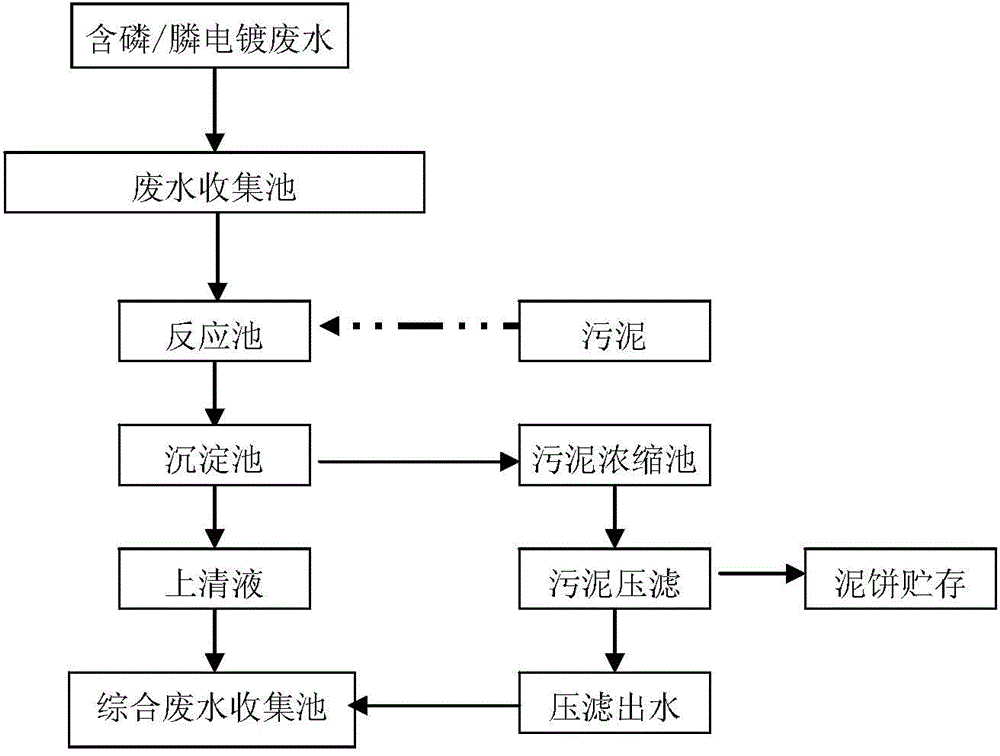

[0036] The phosphorus-containing cyanide-free electroplating is pumped into the comprehensiv...

Embodiment 2

[0040] There is a chemical treatment system for new construction or renovation. The sludge in the sedimentation tank or sludge concentration tank is mixed with phosphorus-containing wastewater in a certain proportion (the ratio of sludge to wastewater is 1:2), and then enters the reaction tank. The pH meter is used to control the sludge or waste water. Phosphorus / phosphine-containing electroplating wastewater is added, and the mud-water mixture enters the sedimentation tank for sedimentation. The effluent enters the comprehensive collection pool or the corresponding waste water collection pool. The sludge enters the sludge thickening tank to concentrate.

[0041] In order to make full use of the sludge during operation, keep the sludge return rate at 25% to 300%.

[0042] The concentration of phosphate in the effluent is <5mg / L.

Embodiment 3

[0044] Phosphorus-containing waste bath is treated before electroplating, the ratio of sludge to bath is 5:1-10:10, the total phosphorus in the effluent is <5mg / L, and the total metal ion concentration is <5mg / L.

[0045] Because the present invention makes full use of the generalized acid-base in electroplating wastewater, electroplating sludge is used to treat phosphorous / phosphine-containing electroplating wastewater, thereby reducing the addition of salinity and alkali in wastewater treatment, reducing sludge output and chemical dosage, and significantly reducing the dissolution rate in wastewater. Non-toxic solids, reduce the amount of electroplating sludge, reduce the cost of wastewater treatment, reduce the salt content in wastewater, reduce environmental pollution, improve the recycling rate of wastewater and the recycling rate of electroplating sludge.

[0046] Taking copper wastewater as an example, copper wastewater contains not only copper pyrophosphate, but also po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com