A device and method for preparing optical fiber preform by vad method

An optical fiber preform and target rod technology, which is applied in the field of optical fiber manufacturing, can solve the problems of high probability of SIO2 particles adhering to the top of the separator, decreased stability, airflow disturbance, etc., to achieve relative position stability, stability improvement, and guaranteed stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

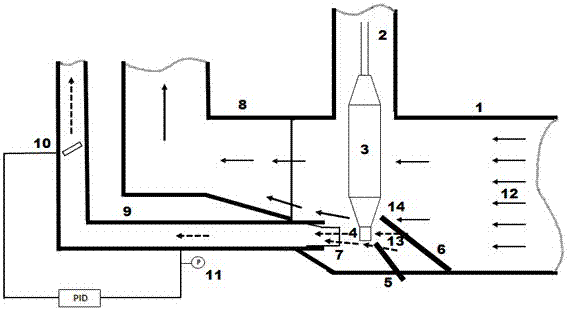

Method used

Image

Examples

Embodiment 1

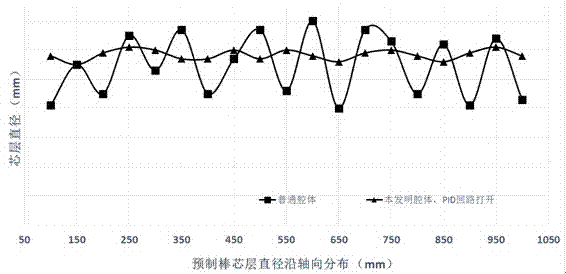

[0035] Embodiment 1: Using a common integrated exhaust duct (comparative example), the cladding and core layer gas smoke is taken away from an integral outlet. At this time, the core layer and cladding flames are at the same distance from the exhaust duct, and the fluctuation of pipeline pressure The effect on cladding and core is the same.

[0036] Install the quartz target rod on the boom and make it rotate, lower the target rod to the appropriate position in the rectangular reaction chamber and face the blowtorch. Introduce hydrogen and oxygen into the blowtorch and ignite it to generate oxyhydrogen flame; feed SiCl4 and GeCl4 gas raw materials into the core torch, which undergo hydrolysis reaction in the oxyhydrogen flame to form SiO2 and GeO2 powders and deposit them on the lower end of the target rod. The core layer of the prefabricated core rod is formed, and at the same time, the SiCl4 gas raw material is passed into the cladding blowtorch, and the generated SiO2 powde...

Embodiment 2

[0038] Embodiment 2: using the cladding-core layer separation type exhaust pipe proposed in the present invention, the distance from the inlet of the cladding exhaust pipe to the axis of the target rod is 400 mm, and the distance from the inlet of the core layer exhaust pipe to the axis of the target rod is adjusted to be 100 mm , turn on the exhaust device, set the pressure of the core layer exhaust pipe to -100Pa, and turn on the PID loop adjustment.

[0039] Install the quartz target rod on the boom and make it rotate, lower the target rod to the appropriate position in the rectangular reaction chamber and face the blowtorch. Introduce hydrogen and oxygen into the blowtorch and ignite it to generate oxyhydrogen flame; feed SiCl4 and GeCl4 gas raw materials into the core torch, which undergo hydrolysis reaction in the oxyhydrogen flame to form SiO2 and GeO2 powders and deposit them on the lower end of the target rod. The core layer of the prefabricated core rod is formed, an...

Embodiment 3

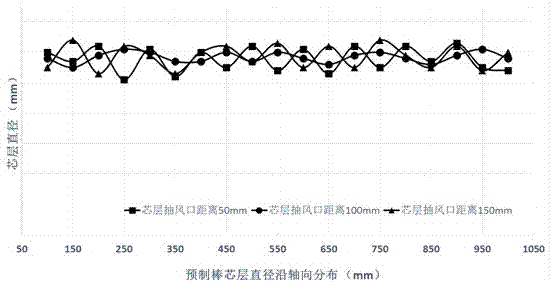

[0041] Embodiment 3: basically the same as Embodiment 2, adjust the distance from the inlet of the core layer exhaust pipe to the axis of the target rod to 50mm, set the pressure of the core layer exhaust pipe to -100Pa, and start the PID loop adjustment of the core layer discharge pipe.

[0042] After the deposited powder rods go through the vitrification process, use the preform analyzer to measure the core diameter of the preform core rod, the refractive index and other parameters to check the deposition quality of the preform ( image 3 ); when the core exhaust pressure is set at -100Pa, and the distance from the exhaust port to the center of the core deposition area is 50mm, the fluctuation range of the preform core diameter along the length direction is ±1.9%, and the standard deviation is 0.40mm. Compared with Example 2, when the air outlet of the core layer is closer to the flame of the core layer, the local draft force is too large, which may not be conducive to the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com