Alkali-efflorescence-free high-waterproofness dry-powder tile joint mixture

A technology of high waterproofness and caulking agent, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. Excellent performance and anti-migration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

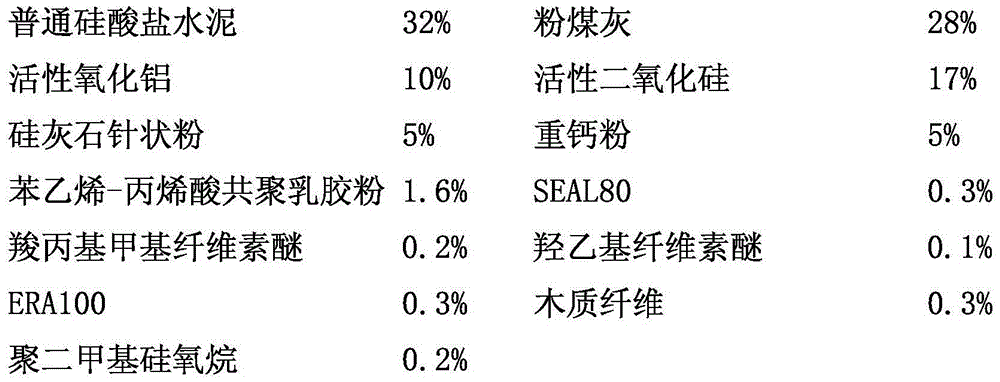

Embodiment 1

[0024] Raw material composition and weight percent proportioning are as follows:

[0025]

[0026] When in use, water with a mass of 18% of the total dry powder mass is added, stirred with an electric mixer for 8 minutes, left to stand for 10 minutes, then stirred with an electric mixer for 8 minutes before use.

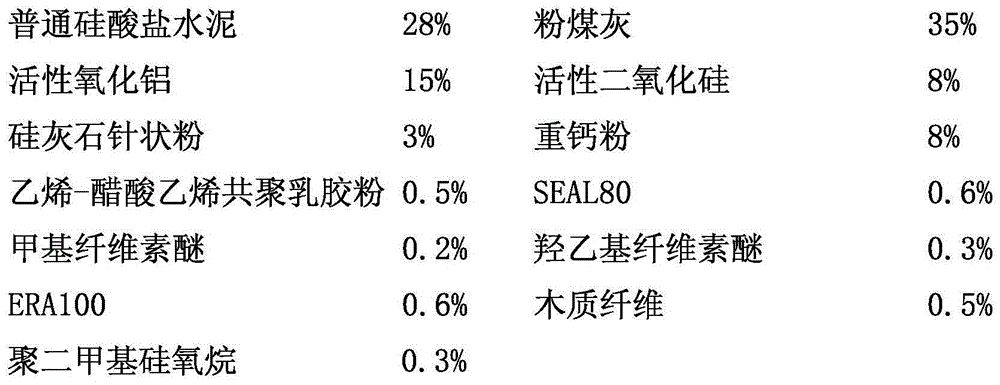

Embodiment 2

[0028] Raw material composition and weight percent proportioning are as follows:

[0029]

[0030] When using, add water with a mass of 20% of the total dry powder mass, stir with an electric mixer for 5 minutes, leave it for 10 minutes, then stir with an electric mixer for 5 minutes before use.

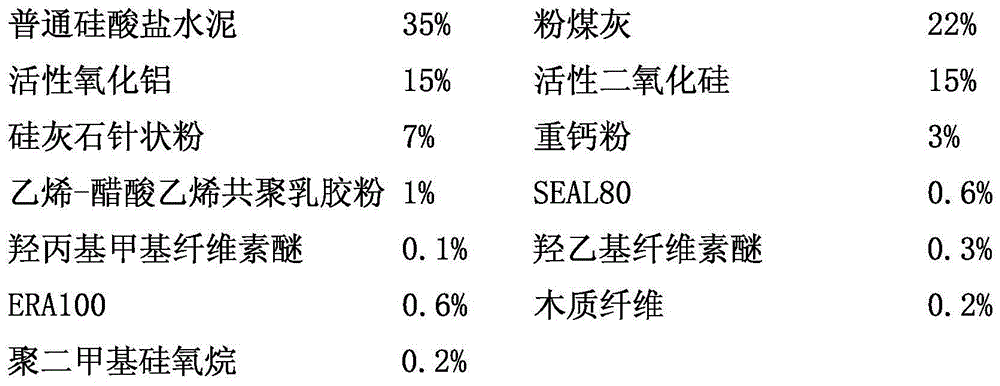

Embodiment 3

[0032] Raw material composition and weight percent proportioning are as follows:

[0033]

[0034] When in use, water with a mass of 16% of the total dry powder mass is added, stirred with an electric mixer for 9 minutes, left to stand for 10 minutes, then stirred with an electric mixer for 9 minutes before use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com