Bamboo charcoal pottery clay water purification inner-container and preparation method thereof

A bamboo charcoal and water purification technology, applied in ceramic products, clay products, other household appliances, etc., can solve the problems of pollution, polluted water pipe network, microorganism and heavy metal pollution, etc., and achieve the effect of simple operation and water quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

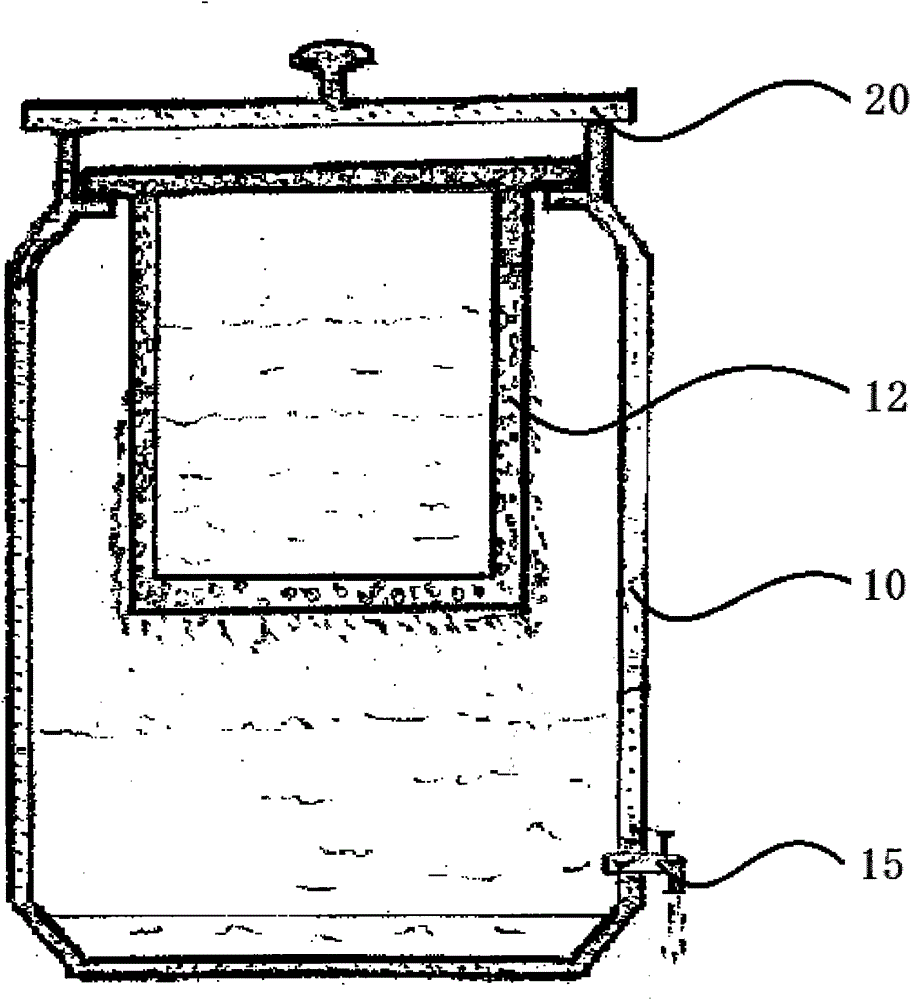

Image

Examples

Embodiment 1

[0021] The bamboo charcoal pottery water purification liner described in the present embodiment, it is formulated by following raw material: the bamboo charcoal particle of 50wt%, the bamboo charcoal powder of 10wt%, the medical stone powder (500-1000 order) of 10wt%, the quartz powder of 5wt% ( 500-1000 mesh) and 25% raw ore purple sand mud; wherein, the particle diameter of the bamboo charcoal particles is 0.5-2mm, the particle diameter of the bamboo charcoal powder is 10-100 μm, and the specific surface area is 200-300m 2 / g. Its preparation method comprises the following process steps: (1) mixing the above-mentioned raw materials to make powder, and adding 20-30wt% of water to the powder and blending into a slurry in mud refining equipment; (2) mixing the slurry in The liner blank (wall thickness 1-2cm) is made in the mold, and then dried at a temperature of 20-80°C for 12-48 hours; (3) The dried liner blank is sintered in a fully enclosed isolated air electric furnace , ...

Embodiment 2

[0030] Compared with Example 1, the bamboo charcoal pottery water purification liner differs only in the ratio of raw materials. Contain in the present embodiment the bamboo charcoal particle of 50wt%, the bamboo charcoal powder of 10wt%, the medical stone powder (500-1000 order) of 8wt%, the quartz powder (500-1000 order) of 4wt%, the raw ore purple sand mud of 25%, 2wt% citric acid, 1wt% sodium tripolyphosphate; wherein, the particle diameter of the bamboo charcoal particles is 0.5-2mm, the particle diameter of the bamboo charcoal powder is 10-100 μm, and the specific surface area is 200-300m 2 / g. The compressive strength of the prepared bamboo charcoal pottery water purification liner is 15-20MPa, which significantly improves the compressive strength of the liner, and the porosity has also reached 60-63%, while the adsorption and filtration effects are the same as those of Example 1 quite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com