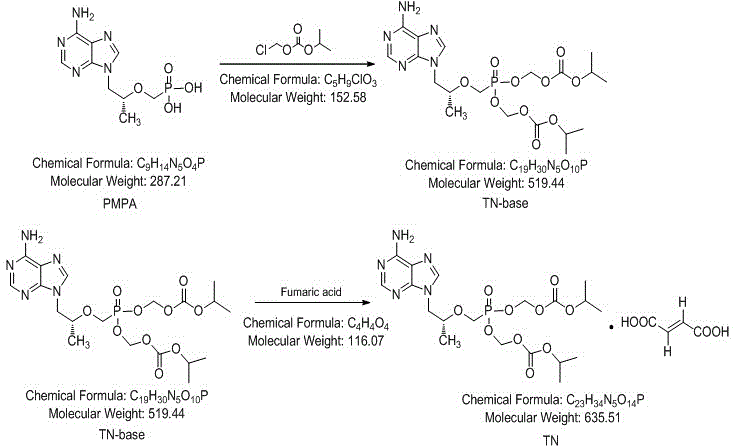

Preparation method of tenofovir disoproxil fumarate

A technology of tenofovir disoproxil fumarate and disoproxil fumarate, which is applied in the field of synthesis of tenofovir disoproxil fumarate, can solve the problem of high organic residues, achieve less side reaction products, overcome organic residues and Excessive side reactants and the effect of removing organic residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

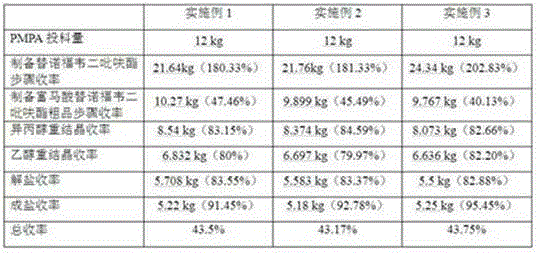

[0033] Embodiments 1 to 3 are specific embodiments of the present invention, wherein embodiment 1 is the best embodiment.

[0034] Example 1

[0035] The preparation method of this embodiment includes the following steps: preparing tenofovir disoproxil, preparing crude tenofovir disoproxil fumarate, and refining tenofovir disoproxil fumarate;

[0036]First, the specific operation of the step of preparing tenofovir disoproxil is:

[0037] 1) Add 49.25kg of N-methylpyrrolidone into the reaction kettle, then add 12kg of tenofovir into the reaction kettle and stir well, then add 17.2kg of triethylamine and 12kg of tetrabutylammonium bromide When the reaction kettle is heated to 46°C under the conditions, add 30.3kg of chloromethyl isopropyl carbonate dropwise, control the reaction temperature not to exceed 55°C, and continue to stir and react for 4 hours, then lower the temperature until the liquid in the reaction kettle is cooled to 40°C 50 kg of cyclohexane was added twice f...

Embodiment 2

[0049] The preparation method of this embodiment includes the following steps: preparing tenofovir disoproxil, preparing crude tenofovir disoproxil fumarate, and refining tenofovir disoproxil fumarate;

[0050] First, the specific operation of the step of preparing tenofovir disoproxil is:

[0051] 1) Add 49.25kg of N-methylpyrrolidone into the reaction kettle, then add 12kg of tenofovir into the reaction kettle and stir well, then add 17.2kg of triethylamine and 12kg of tetrabutylammonium bromide When the reaction kettle is heated to 46°C under the conditions, add 30.3kg of chloromethyl isopropyl carbonate dropwise, control the reaction temperature not to exceed 55°C, and continue to stir and react for 4 hours, then lower the temperature until the liquid in the reaction kettle is cooled to 40°C 50 kg of cyclohexane was added twice for washing, stirred for 30 minutes, allowed to stand for 15 minutes to separate layers, and the cyclohexane phase was discarded, and the liquid af...

Embodiment 3

[0063] 1) Add 49.25kg of N-methylpyrrolidone into the reaction kettle, then add 12kg of tenofovir into the reaction kettle and stir well, then add 17.2kg of triethylamine and 12kg of tetrabutylammonium bromide When the reaction kettle is heated to 46°C under the conditions, add 30.3kg of chloromethyl isopropyl carbonate dropwise, control the reaction temperature not to exceed 55°C, and continue to stir and react for 4 hours, then lower the temperature until the liquid in the reaction kettle is cooled to 40°C 50 kg of cyclohexane was added twice for washing, stirred for 30 minutes, allowed to stand for 15 minutes to separate layers, and the cyclohexane phase was discarded, and the liquid after washing was retained;

[0064] 2) Add 50 kg of water and 110 kg of ethyl acetate to the washed liquid for extraction, separate layers, and keep the ethyl acetate phase. Wash the aqueous phase twice with 55kg ethyl acetate twice, and combine the ethyl acetate phases;

[0065] 3) Wash the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com