Epoxy resin composition, purpose of same, and fillings for epoxy resin composition

A technology of epoxy resin and composition, applied in the direction of epoxy resin glue, dyed silicone compound treatment, adhesive type, etc., can solve research problems and achieve the effect of excellent formability and excellent flame resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

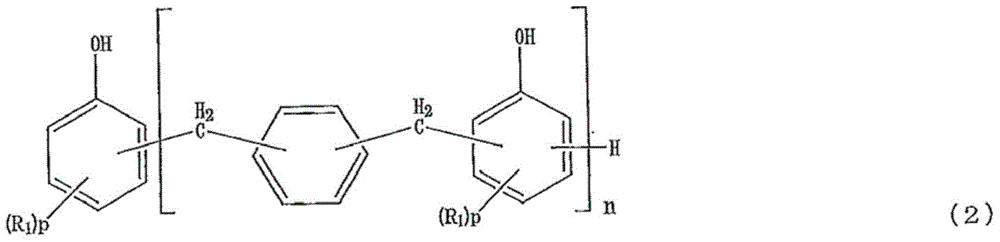

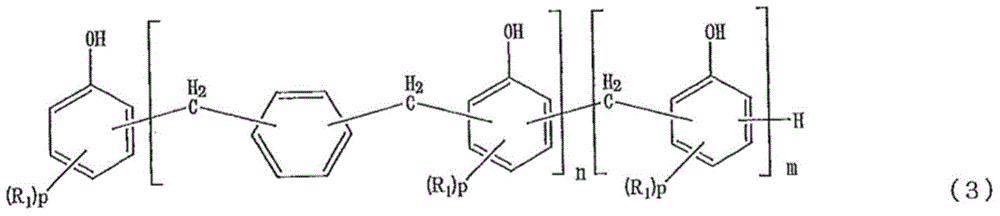

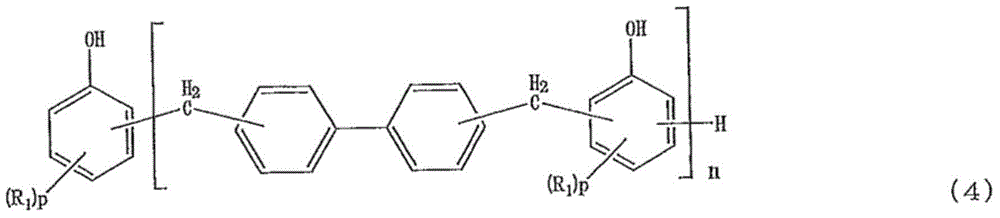

Method used

Image

Examples

Embodiment 1

[0112] As shown in Table 1, 100 g (100 parts by mass) of YX-4000 as an epoxy resin and 57 g of Hardener 1 (phenol formaldehyde type phenolic resin) as a hardener were mixed under the temperature conditions shown in Table 1 using a twin-shaft kneader. (57 parts by mass), 2.7 g (2.7 parts by mass) of triphenylphosphine as a hardening accelerator, 532 g (532 parts by mass) of silica powder (MSR-2212) as a filler, and phenyltrimethoxy 1,424 g (424 parts by mass) of magnesia powder treated with oxysilane was kneaded to obtain a kneaded product of an epoxy resin composition. Observe the mixing steps at this time.

[0113] After cooling the obtained kneaded product to room temperature, it was pulverized by a pulverizer to be powdered. This powder was press-molded with a specific die to form an ingot made of an epoxy resin composition. This ingot was used as a sample, and the fluidity (swirl flow) was evaluated. Furthermore, the sample was formed into a specific size by a transfer ...

Embodiment 2

[0115] As shown in Table 1, an epoxy resin composition was obtained in the same manner as in Example 1, using hardener 2 (biphenyl aralkyl type phenol resin) instead of hardener 1 (phenol formaldehyde type phenol resin) as a hardener. of mixes. In addition, its evaluation is performed.

Embodiment 3

[0117] As shown in Table 1, magnesium oxide powder 2 whose surface has been treated with N-2-aminoethyl-3-aminopropyltrimethoxysilane is used instead of magnesium oxide powder 1, and epoxy resin is obtained in the same manner as in Example 2. A kneaded product of a resin composition. In addition, its evaluation is performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com