Addition type liquid silicone rubber and manufacturing method thereof

A liquid silicone rubber, addition molding technology, applied in the field of silicone liquid rubber, can solve the problem of not meeting the comprehensive performance requirements of silicone rubber such as strength, elasticity, viscosity and light transmittance, and achieves easy industrial application, easy construction, Simple and easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

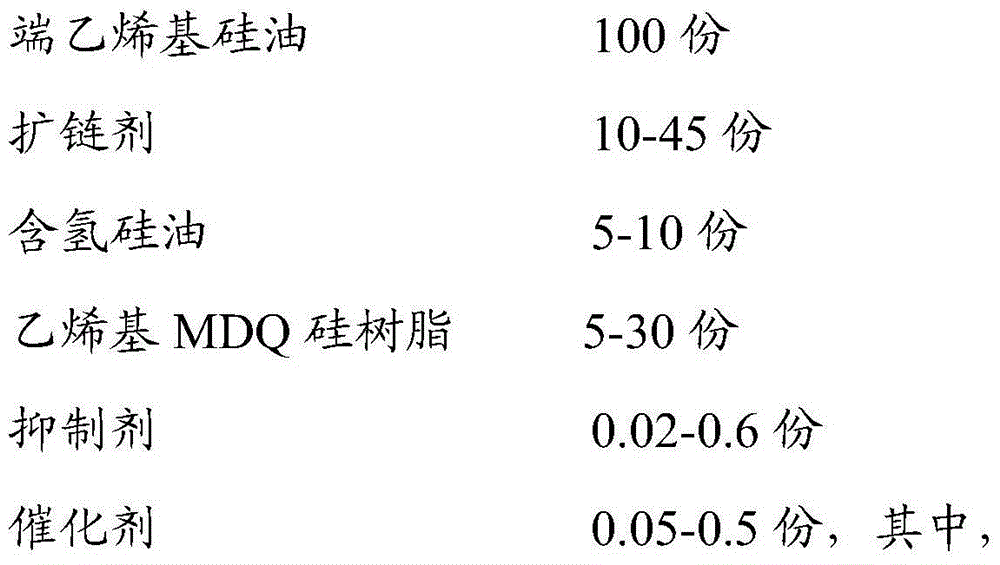

[0030] A kind of addition-type liquid silicone rubber of the present embodiment comprises the following raw materials in parts by weight:

[0031]

[0032] The viscosity of the vinyl-terminated polydimethylsiloxane is 5000mPa.s;

[0033] The chain extender is terminal hydrogen-containing silicone oil, and the general structural formula is (HMe 2 )Si(Me 2 SiO) n Si(Me 2 H), the viscosity is 150mPa.s;

[0034] The hydrogen-containing silicone oil contains at least 3 Si-H in each molecule, the viscosity is 50mPa.s, and the hydrogen content is 0.05%;

[0035] The structural formula of described vinyl MDQ silicone resin is as follows: (ViMe 2 SiO 1 / 2 )a(Me 3 SiO 1 / 2 ) b (Me 2 SiO) c (SiO 2 ) d , in the formula: (a+b) / d=0.5, c / d=0.5, the massfraction of Vi is 0.5%;

[0036] The inhibitor is 1-ethynyl-1-cyclohexanol;

[0037] The catalyst is chloroplatinic acid-isopropanol complex.

[0038] The preparation method of above-mentioned addition type liquid silicone rub...

Embodiment 2

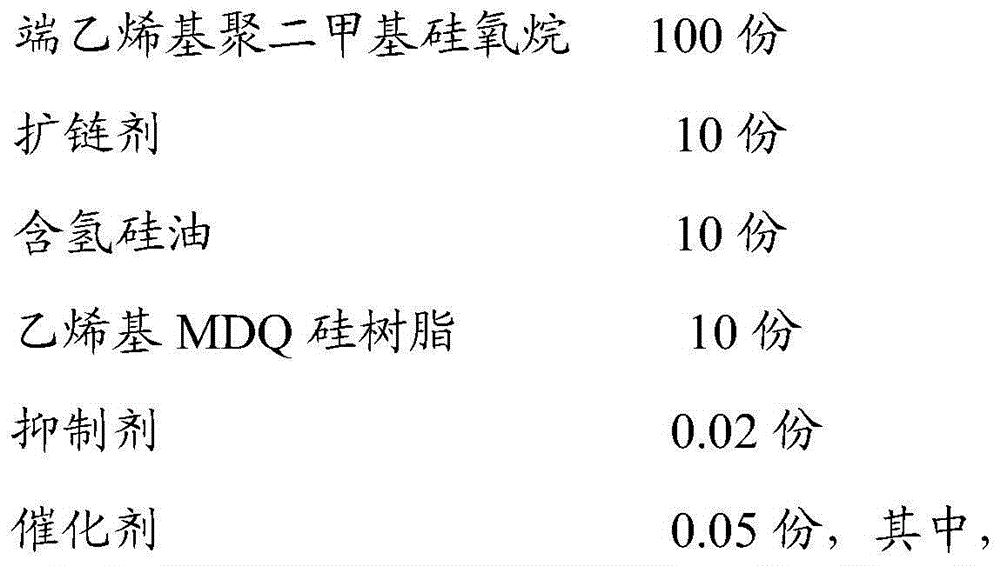

[0043] A kind of addition-type liquid silicone rubber of the present embodiment comprises the following raw materials in parts by weight:

[0044]

[0045] The viscosity of the vinyl-terminated polydimethylsiloxane is 10000mPa.s;

[0046] The chain extender is terminal hydrogen-containing silicone oil, and the general structural formula is (HMe 2 )Si(Me 2 SiO) n Si(Me 2 H), the viscosity is 500mPa.s;

[0047] The hydrogen-containing silicone oil contains at least 3 Si-H in each molecule, has a viscosity of 150mPa.s, and contains 0.3% hydrogen;

[0048] The structural formula of described vinyl MDQ silicone resin is as follows: (ViMe 2 SiO 1 / 2 )a(Me 3 SiO 1 / 2 ) b (Me 2 SiO) c (SiO 2 ) d , where: (a+b) / d=0.8, c / d=1.0, the massfraction of Vi is 0.7%;

[0049] The inhibitor is 2-methyl-3-butynyl-2-alcohol;

[0050] The catalyst is chloroplatinic acid-divinyltetramethyldisiloxane complex.

[0051] The preparation method of above-mentioned addition type liquid sil...

Embodiment 3

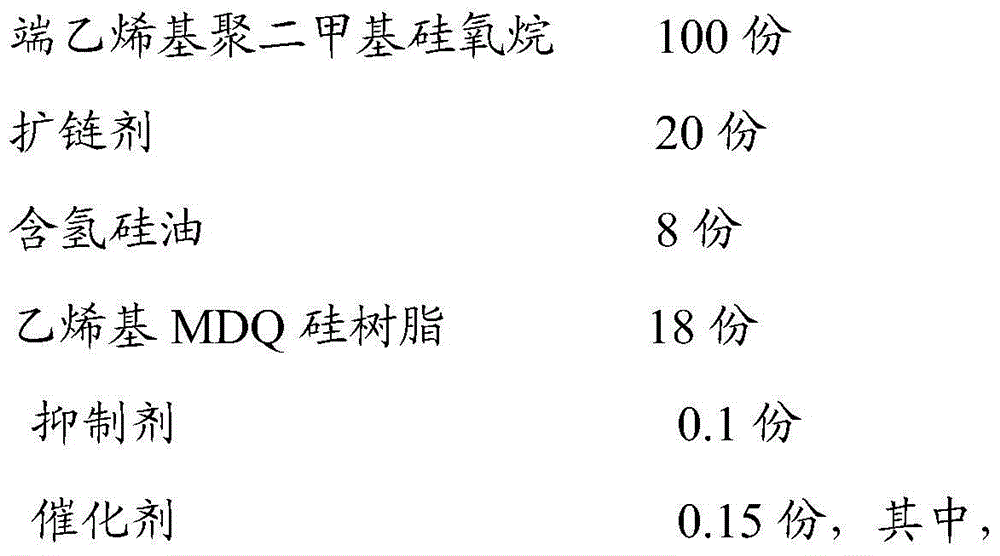

[0056] A kind of addition-type liquid silicone rubber of the present embodiment comprises the following raw materials in parts by weight:

[0057]

[0058] The viscosity of the vinyl-terminated polydimethylsiloxane is 12000mPa.s;

[0059] The chain extender is terminal hydrogen-containing silicone oil, and the general structural formula is (HMe 2 )Si(Me 2 SiO) n Si(Me 2 H), the viscosity is 400mPa.s;

[0060] The hydrogen-containing silicone oil contains at least 3 Si-H in each molecule, the viscosity is 500mPa.s, and the hydrogen content is 1.2%;

[0061] The structural formula of described vinyl MDQ silicone resin is as follows: (ViMe 2 SiO 1 / 2 )a(Me 3 SiO 1 / 2 ) b (Me 2 SiO) c (SiO 2 ) d , where: (a+b) / d=1.5, c / d=0.6, the mass fraction of Vi is 2.0%;

[0062] The inhibitor is 3-methyl-1-dodeyn-3-ol;

[0063] The catalyst is chloroplatinic acid-divinyltetramethyldisiloxane complex.

[0064] The preparation method of above-mentioned addition type liquid silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com