A kind of waterborne epoxy antistatic floor coating topcoat and preparation method thereof

A technology of floor coatings and water-based epoxy resins, applied in the direction of epoxy resin coatings, conductive coatings, coatings, etc., can solve the problems of high organic volatiles, high toxicity, and strong odor, and achieve simple preparation methods and low organic volatiles. The effect of less material and lower cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

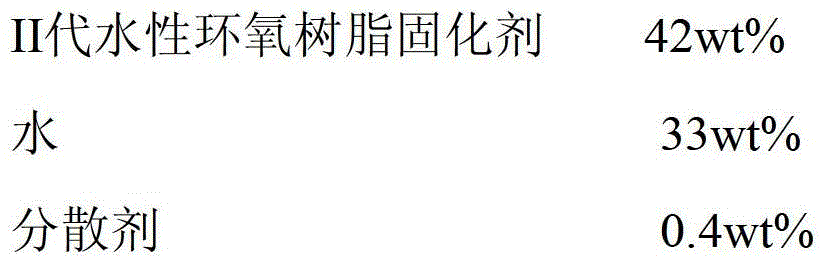

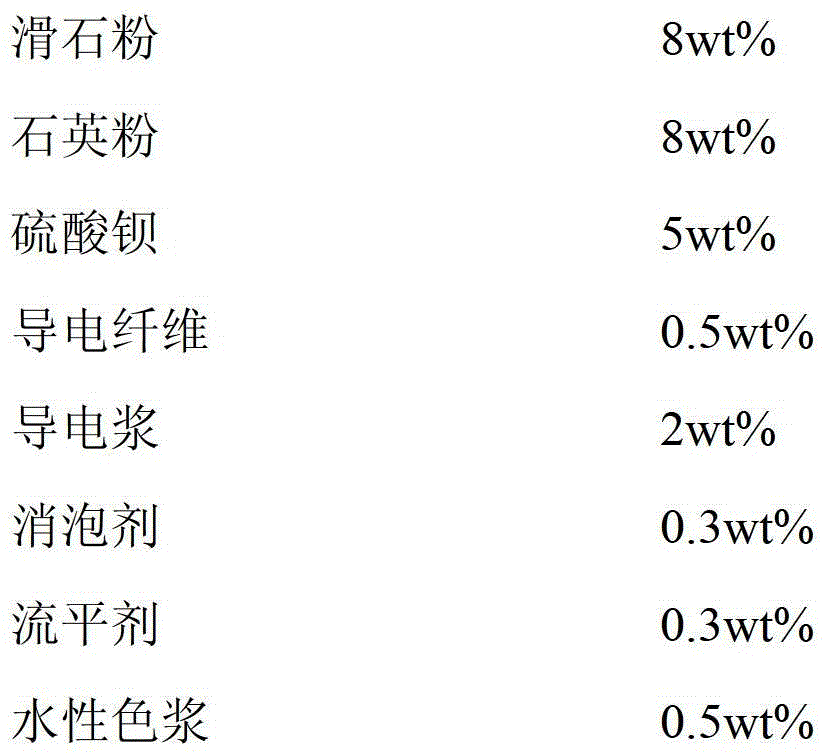

[0031] Weigh each component according to the following mass percentages:

[0032] A component:

[0033]

[0034]

[0035] B component:

[0036] Bisphenol A type epoxy resin (epoxy equivalent is 186g / eq) 80wt%

[0037] Butyl glycidyl ether 20wt%

[0038] The production process of component A is divided into eight steps:

[0039] Step 1: Add the measured II-generation water-based epoxy resin curing agent, 16.5wt% water, and dispersant into the material tank, disperse and stir evenly.

[0040] Step 2: Add quartz powder, barium sulfate, and talcum powder into the material tank and continue to disperse and stir evenly.

[0041] Step 3: Grind the above uniformly stirred and dispersed materials through a sand mill, and the fineness is controlled to be ≤50 μm.

[0042] Step 4: Add the conductive fiber, the conductive paste and the remaining 16.5wt% of water and stir in the disperser to disperse evenly.

[0043] Step 5: Filter with a 200-mesh filter.

[0044] Step 6: Add w...

Embodiment 2

[0052] Weigh each component according to the following mass percentages:

[0053] A component:

[0054]

[0055] B component:

[0056] Bisphenol A epoxy resin (epoxy equivalent 1866g / eq) 85%

[0057] Butyl glycidyl ether 5%

[0058] C12-Myristyl Glycidyl Ether 10%

[0059] The production process of component A is divided into eight steps:

[0060] Step 1: Add the measured II-generation water-based epoxy resin curing agent, 15% water, and dispersant into the material tank, disperse and stir evenly.

[0061] Step 2: Add titanium dioxide, silicon micropowder, and talcum powder into the material tank and continue to disperse and stir evenly.

[0062] Step 3: Grind the above dispersed and stirred materials through a sand mill, and the fineness is controlled to be ≤50 μm.

[0063] Step 4: Add conductive fiber, conductive paste and the remaining 15% of water to disperse and stir evenly in a disperser.

[0064] Step 5: Filter with a 200-mesh filter.

[0065] Step 6: Add color...

Embodiment 3

[0073] Weigh each component according to the following mass percentages:

[0074] A component:

[0075]

[0076] B component:

[0077] Bisphenol A epoxy resin (epoxy equivalent 1866g / eq) 90%

[0078] 1,4-Butanediol diglycidyl ether 5%

[0079] C12-Myristyl Glycidyl Ether 5%

[0080] The production process of component A is divided into eight steps:

[0081] Step 1: Add the measured II-generation water-based epoxy resin curing agent, 14% water, and dispersant into the material tank, disperse and stir evenly.

[0082] Step 2: Add titanium dioxide, silicon micropowder, and talcum powder into the material tank and continue to disperse and stir evenly.

[0083] Step 3: Grind the above dispersed and stirred materials through a sand mill, and the fineness is controlled to be ≤50 μm.

[0084] Step 4: Add conductive fiber, conductive paste and the remaining 14% of water to disperse and stir evenly in a disperser.

[0085] Step 5: Filter with a 200-mesh filter.

[0086] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com