Adhesive sheet and preparation method thereof

An adhesive sheet, adhesive resin technology, applied in the direction of adhesive types, ester copolymer adhesives, chemical instruments and methods, etc., can solve the problem of residual gaps or air bubbles in the frame, achieve simple manufacturing process, avoid frame Residual air bubbles, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

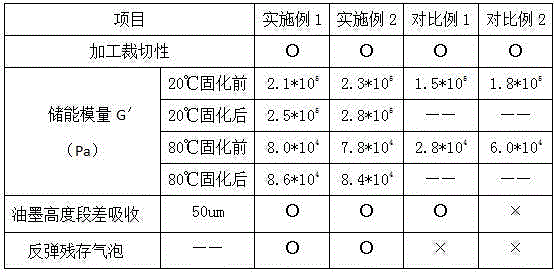

Examples

Embodiment 1

[0040] Preparation of Adhesive Layer A : 100 parts of solvent-based acrylate copolymer adhesive resin YTF-03 (weight average molecular weight of 1 million, solid content of 30%) with a Tg of -46°C and a hydroxyl value of 29 mgKOH / g and 1 part of unsaturated bond-containing acrylic acid Prepolymer and 0.04 parts of UV photoinitiator 184 are mixed uniformly to prepare coating solution;

[0041] Preparation of support layer B : 100 parts of solvent-based acrylate copolymer adhesive resin YTF-04 (weight-average molecular weight: 950,000, solid content: 35%) with a Tg of -44°C and an acid value of 14 mgKOH / g and 0.4 parts of epoxy glycidol Prepare the coating liquid after mixing and stirring the ether curing agent evenly;

[0042] Adhesive sheet preparation : Then the adhesive layer A of the upper and lower layers and the support layer B of the middle layer are coated with a three-layer slit co-extrusion die and extruded simultaneously to form an ABA structural adhesive resin...

Embodiment 2

[0045] The preparation of adhesive layer A and support layer B is the same as in Example 1;

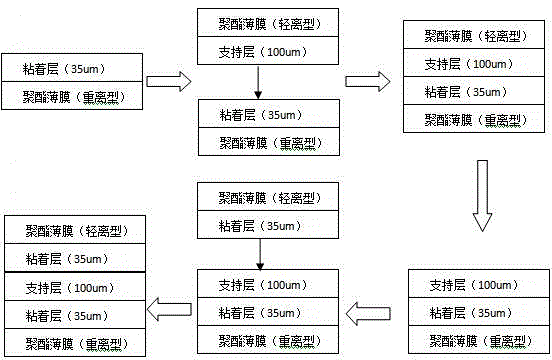

[0046] Adhesive sheet preparation : Coating the adhesive layer A coating solution on the heavy-release polyester film layer, and volatilizing the solvent in an oven at 90°C for 3 minutes, so that the dry thickness is 35um, and then lightly release the polyester film layer; the support layer Coating solution B is coated on the heavy-release polyester film layer, and after the solvent is volatilized in an oven at 90°C for 7 minutes, the dry thickness is 100um, and then compounded with the heavy-release polyester film layer; figure 1 The multiple composite processes shown in the figure obtain the adhesive sheet;

[0047] UV radiation curing: After the above-mentioned adhesive sheet is attached to the laminate, it is placed in an autoclave for degassing. The pressure of degassing is 0.3Mpa; the temperature is 40°C; the time is 60min, and finally the laminate is cured and fixed by ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com